| –

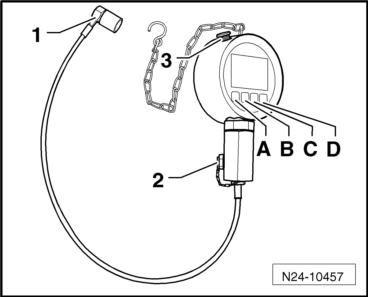

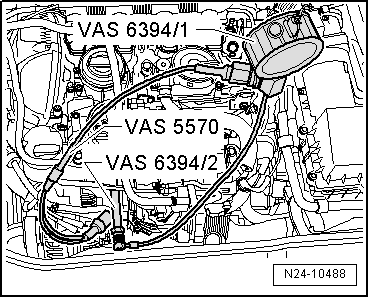

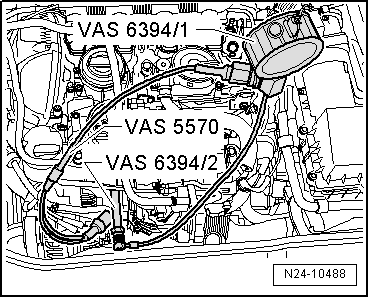

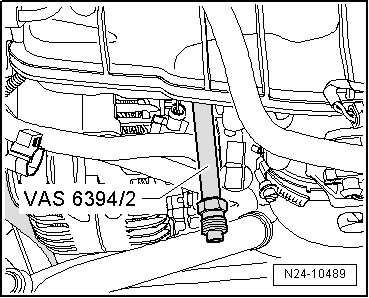

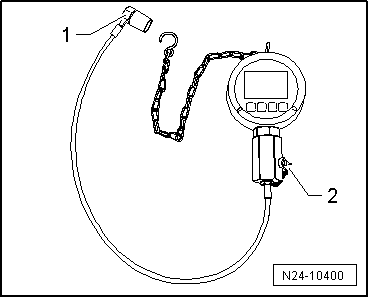

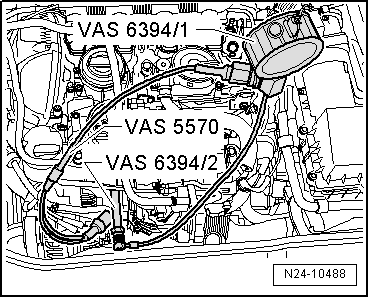

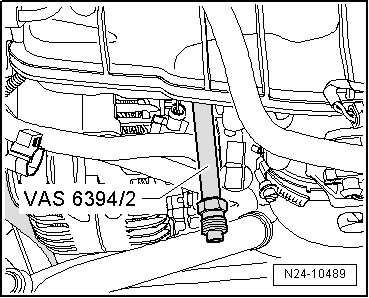

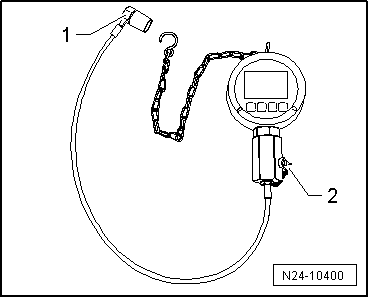

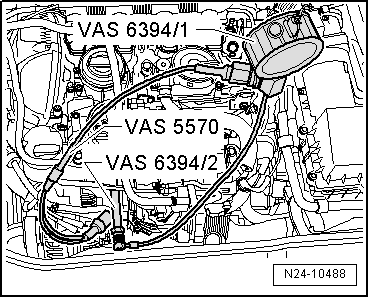

| Connect pressure line of pressure gauge -VAS 6394/1- to adapter -VAS 6394/2-. |

| –

| Compare the pressure indicated by pressure gauge -VAS 6394/1- with the actual pressure value on the vehicle diagnostic tester. |

| l

| The pressure readings must not deviate by more than 5 bar. |

| –

| If the deviation is more than 5 bar, test a new fuel pressure sender -G247-. |

WARNING | The fuel system is pressurised. The fuel pressure in the high-pressure part of the injection system must be reduced to a residual pressure prior to opening; for procedure see → Chapter. |

|

| –

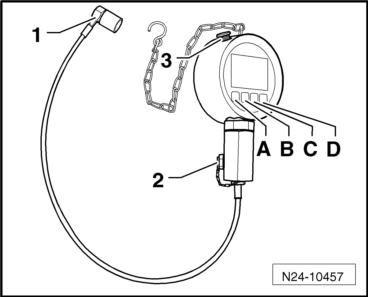

| Screw a new fuel pressure sender -G247- into the pressure gauge -VAS 6394/1-. |

| –

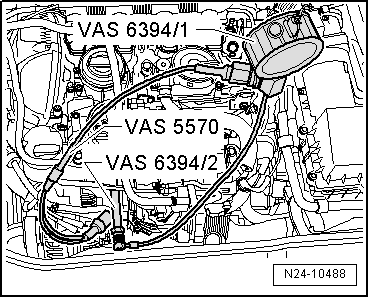

| Repeat the test with the new fuel pressure sender -G247- and compare the two pressure values. |

| If the two values still do not agree: |

| –

| Install the new fuel pressure sender -G247- → Chapter. |

|

|

|

Note

Note

Note

Note