A3 Mk2

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

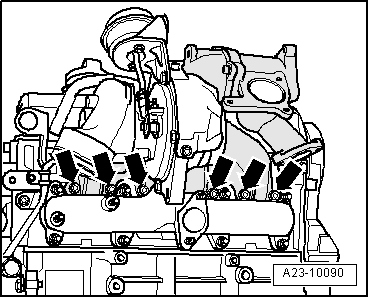

| Component | Nm | |||||

| Intake manifold to cylinder head | 22 | |||||

| Exhaust gas recirculation cooler to intake manifold | 22 | |||||

| Heat shield to exhaust manifold | 25 | |||||

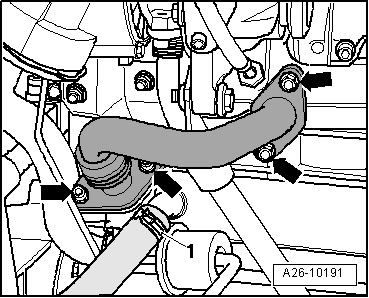

| Support for turbocharger to: | Cylinder block | 60 | ||||

| Turbocharger | 25 | |||||

| Oil pipe to turbocharger | 15 | |||||

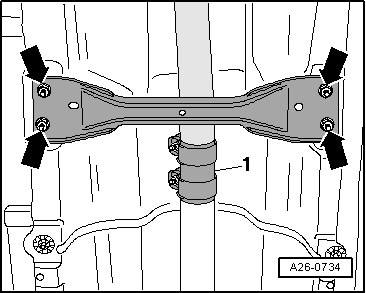

| Pendulum support to: | Gearbox | 40 + 90° 1)2) | ||||

| Subframe | 100 + 90° 1)2) | |||||

| Drive shaft heat shield to cylinder block | 35 | |||||

| Exhaust gas recirculation valve -N18- to intake manifold | 10 | |||||

| Intake manifold flap motor -V157- to intake manifold | 10 | |||||

| Air pipe to bracket | 10 | |||||

| ||||||