| –

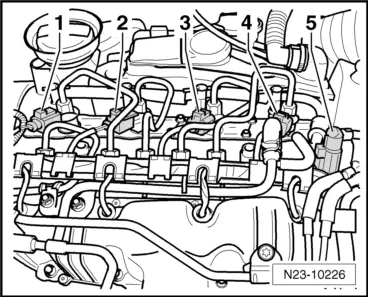

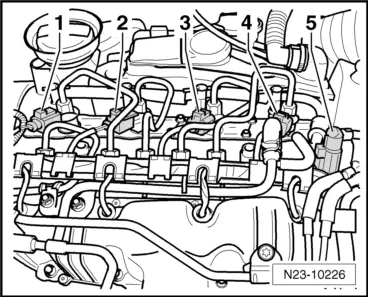

| Detach electrical connector -5- from fuel pressure regulating valve -N276-. |

Note | This prevents fuel from being injected when starter is operated. |

| –

| Connect the 4 hoses onto return line connections of all 4 injectors. |

| –

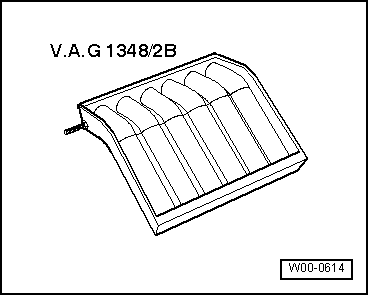

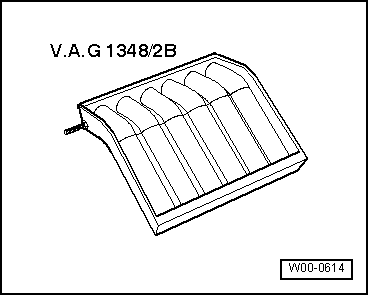

| Run the 4 hoses into injection rate comparison meter -V.A.G 1348/2 B-. |

| –

| Operate starter three times. (Wait approx. 20 seconds each time after operating starter to prevent it from overheating.) |

| l

| Specification of return flow rate: 0 ml |

| –

| If fuel comes out of one injector, that injector must be renewed. |

| –

| Re-attach electrical connector on fuel pressure regulating valve -N276-. |

| Installing fuel return lines |

| –

| Renew O-rings for all return line connections. |

Note | Lubricate all O-rings with engine oil or assembly oil before installing. |

| –

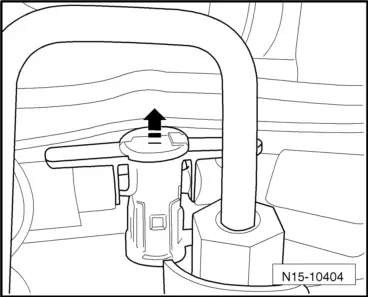

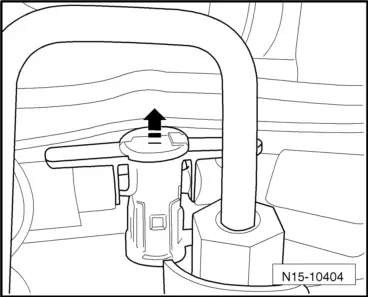

| Push the return line connections carefully over the new seals and onto the injectors. The catch should engage audibly. Then press release pin down carefully. |

| –

| Erase entry in event memory using a diagnostic tester. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note