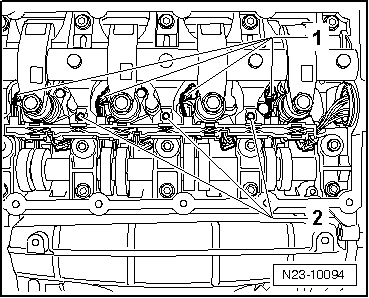

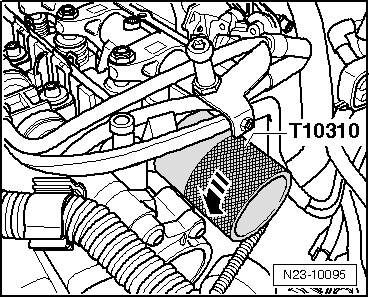

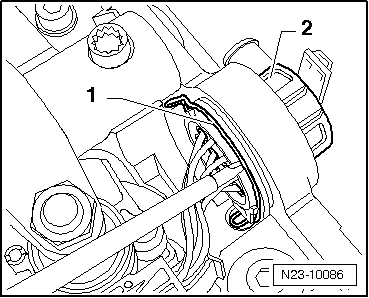

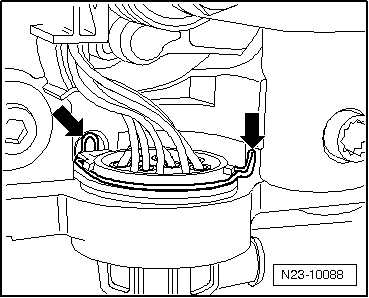

Removing and installing electrical wiring harness for unit injectors

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

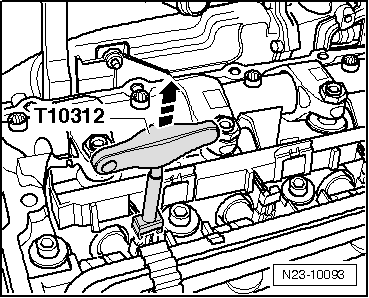

| Component | Nm |

| Electrical wiring harness to cylinder head | 10 |

Caution

Caution