A3 Mk2

|

| Grease | Outer joint Ø | Inner joint Ø |

| G 000 603 | 90 mm | 100 mm |

| Total quantity | 120 g | 110 g |

| In joint | 80 g | 50 g |

| In boot | 40 g | 60 g |

Note

Note

|

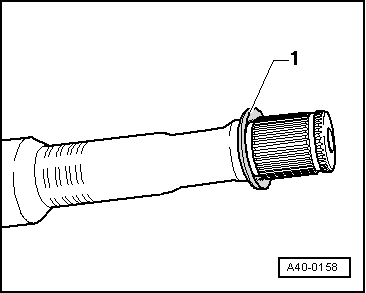

| 1 - | Outer constant velocity joint |

| q | Renew only as complete unit |

| q | Checking → Chapter |

| q | Removing → Fig. |

| q | Greasing ⇒ see table → Anchor |

| q | Installing → Anchor |

| q | Grease splines on drive shaft lightly with grease used in joint when fitting joint onto drive shaft |

| 2 - | Bolt |

| q | Always renew if removed |

| q | Different versions; for correct version refer to → Electronic parts catalogue |

| q | Hexagon bolt = 200 Nm + turn 180° further; loosening and tightening → Chapter |

| q | Twelve-point ribbed bolt = 70 Nm + turn 90° further; loosening and tightening → Chapter |

| q | Twelve-point bolt without ribbing = 200 Nm + turn 180° further; loosening and tightening → Chapter |

| q | Before securing, clean the threads in the CV joint using a thread tap. |

| 3 - | Profile shaft |

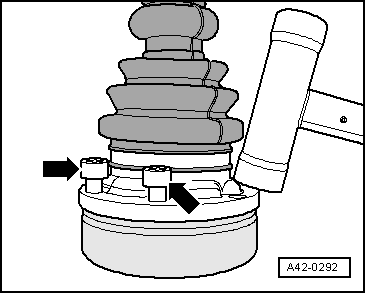

| 4 - | Hose clip |

| q | Renew |

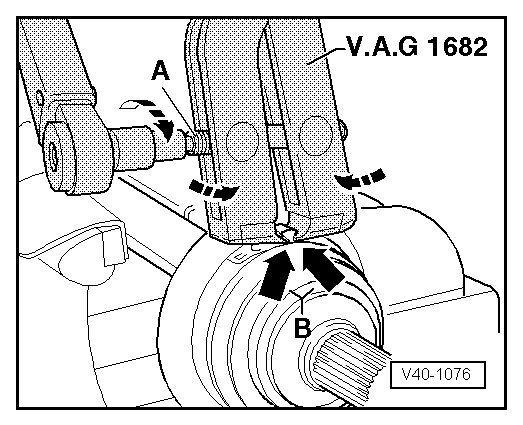

| q | Tightening → Fig. or → Fig. |

| 5 - | Boot for outer constant velocity joint |

| q | Without vent hole |

| q | Check for splits and chafing |

| 6 - | Hose clip |

| q | Renew |

| q | Tightening → Fig. or → Fig. |

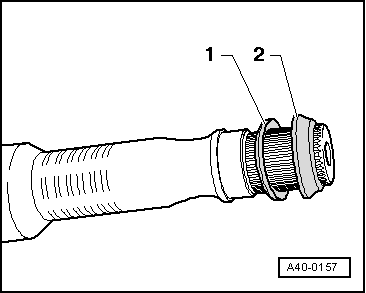

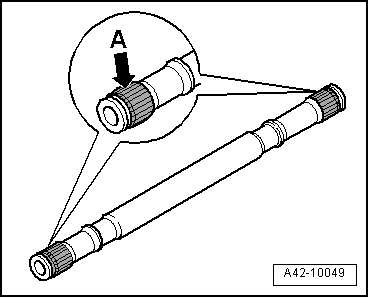

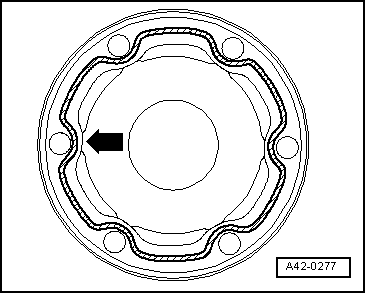

| 7 - | Dished spring |

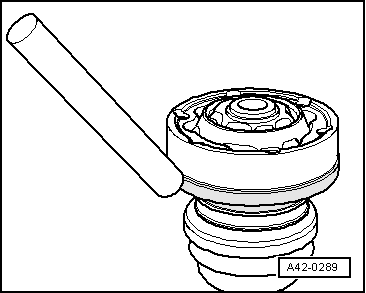

| q | Installation position → Fig. |

| 8 - | Spacer ring (plastic) |

| q | Installation position → Fig. |

| 9 - | Circlip |

| q | Renew |

| q | Insert in groove on shaft |

| 10 - | Boot for inner constant velocity joint |

| q | Without vent hole |

| q | Check for splits and chafing |

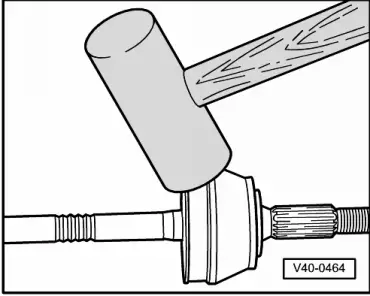

| q | Drive off constant velocity joint with a drift |

| q | Before fitting on constant velocity joint, coat sealing surface with D 454 300 A2 |

| 11 - | Hose clip |

| q | Renew |

| q | Tightening → Fig. or → Fig. |

| 12 - | Lock plate |

| 13 - | Multi-point socket head bolt |

| q | Always renew if removed |

| q | Initial tightening torque: 10 Nm in diagonal sequence |

| q | Tightening torque, M8: 40 Nm in diagonal sequence |

| q | Tightening torque, M10: 70 Nm in diagonal sequence |

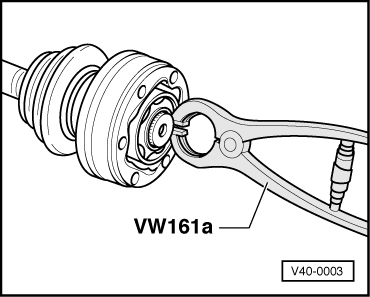

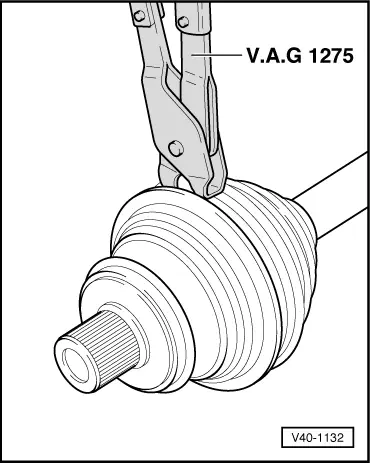

| 14 - | Circlip |

| q | Renew |

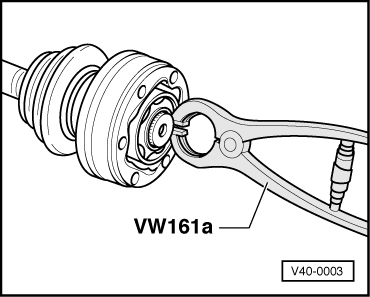

| q | Removing and installing with -VW 161 A- → Fig. |

| 15 - | Gasket |

| q | Adhesive surface on constant velocity joint must be free of oil and grease |

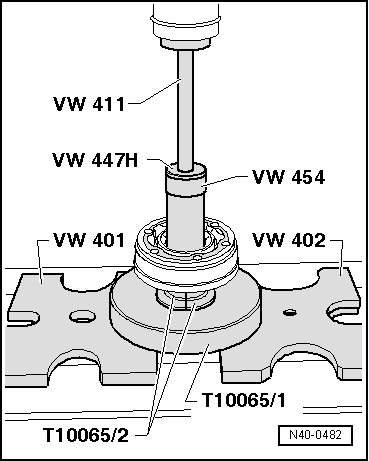

| 16 - | Inner constant velocity joint |

| q | Renew only as complete unit |

| q | Checking → Chapter |

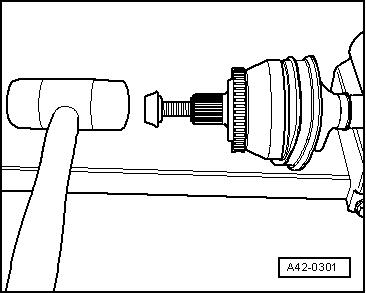

| q | Pressing off → Fig. |

| q | Greasing ⇒ see table → Anchor |

| q | Pressing on → Anchor |

| q | Grease splines on drive shaft lightly with grease used in joint when fitting joint onto drive shaft |

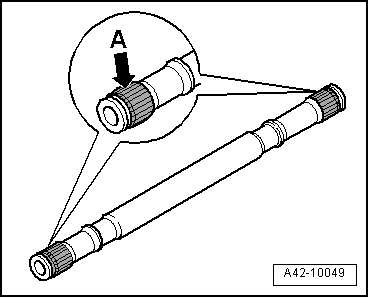

| 17 - | Dished spring |

| q | Installation position → Fig. |

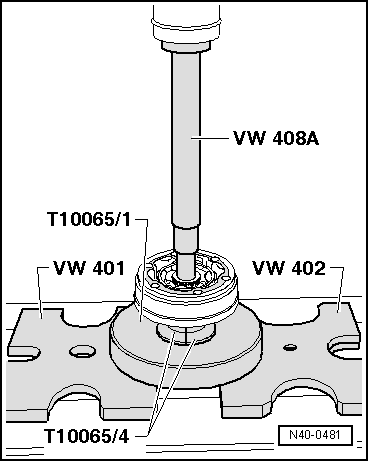

| Special tools and workshop equipment required |

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

| t | Press tool -VW 408 A- |

| t | Press tool -VW 411- |

| t | Tube -VW 416 B- |

| t | Thrust plate -VW 447 H- |

| t | Circlip pliers -VW 161 A- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

| t | Clamp tensioner -V.A.G 1682- |

| t | Assembly tool -T10065- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|