| –

| Loosen cap nut and remove wiring lug from screw connection. |

| –

| Check screw connection for corrosion, dirt, etc. |

| –

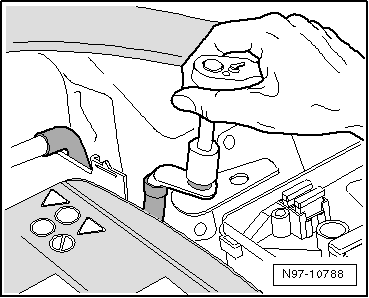

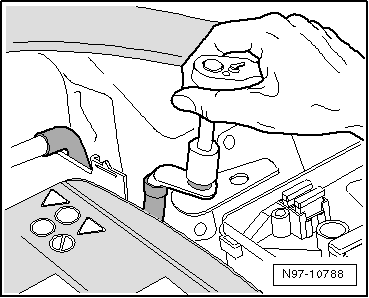

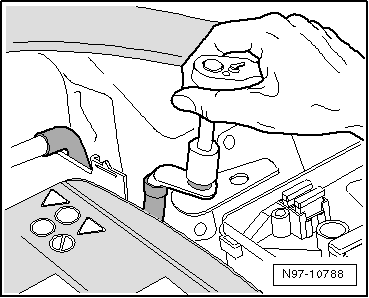

| Select appropriate adapter and corresponding sanding pad for screw connection. |

Caution | Increased corrosion due to exposed copper layer. |

| Do not sand away the tin plating to such an extent that the copper layer underneath becomes visible. Galvanic effects can cause increased corrosion. |

|

Note | As the thickness of the tin coating varies, it is necessary to clean the screw connection in several stages and check it in between. |

| –

| Apply adapter to screw connection and sand corrosion and dirt off by rotating adapter. |

| –

| Check screw connection and if necessary re-sand. |

| –

| Bolt screw connection together with locating element (if fitted) and tighten to specified torque. |

Note | To ensure optimum contact, tighten all screw-type connections to specified torque after cleaning. |

| –

| Protect connection from corrosion by applying corresponding anti-corrosion agent → Chapter. |

|

|

|

Note

Note Note

Note Note

Note

Note

Note Note

Note Note

Note