A4 Cabriolet Mk2

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

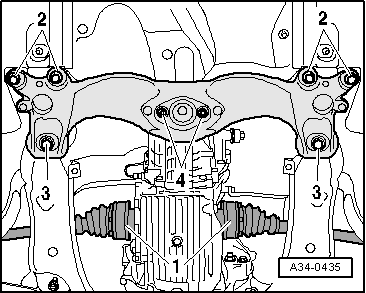

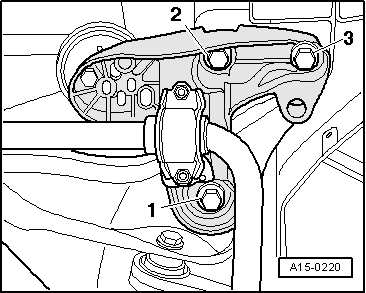

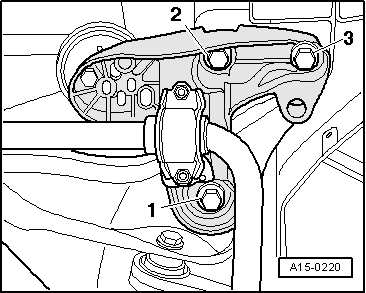

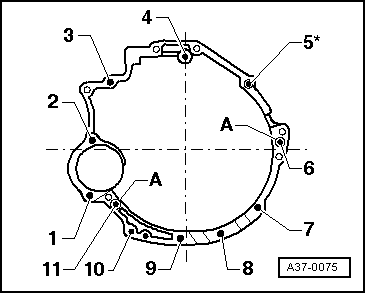

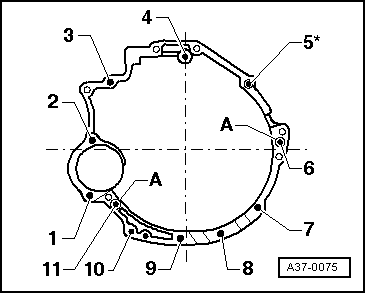

| Item | Bolt | Nm |

| 1 1) | M12 x 75 | 65 |

| 2 1) | M12 x 90 | 65 |

| 3 2) | M12 x 75 | 65 |

| 4, 6 | M12 x 90 | 65 |

| 5 2) | M12 x 110 | 65 |

| 7 3) | M10 x 50 | 45 |

| 8, 9, 10 | M10 x 45 | 45 |

| 11 4) | M12 x 110 | 65 |

| A | Dowel sleeves for centralising | |

| 1) Secures starter to gearbox 2) With bracket for wiring harness 3) Hammer head bolt with nut 4) With nut | ||

|

|

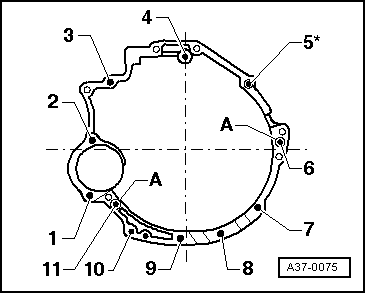

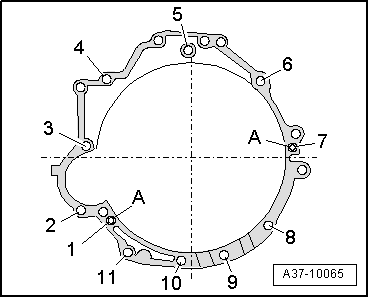

| Item | Bolt | Nm |

| 1 1) | M12 x 75 | 65 |

| 2 1) | M12 x 90 | 65 |

| 3 2) | M12 x 75 | 65 |

| 4, 6 | M12 x 90 | 65 |

| 5 2) | M12 x 110 | 65 |

| 7 3) | M10 x 50 | 45 |

| 8, 9, 10 | M10 x 45 | 45 |

| 11 4) | M12 x 110 | 65 |

| A | Dowel sleeves for centralising | |

| 1) Secures starter to gearbox 2) With bracket for wiring harness 3) Hammer head bolt with nut 4) With nut | ||

|

|

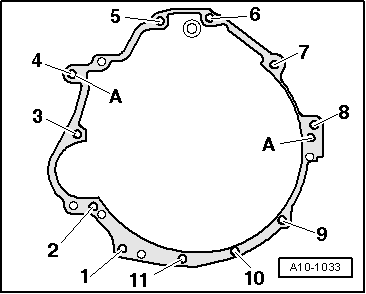

| Item | Bolt | Nm |

| 1 1) | M12 x 80 | 65 |

| 2 1) | M12 x 95 | 65 |

| 3 2) | M12 x 80 | 65 |

| 4, 6 | M12 x 95 | 65 |

| 5 2) | M12 x 110 | 65 |

| 7 3) | M10 x 50 | 45 |

| 8, 9, 10 | M10 x 45 | 45 |

| 11 4) | M12 x 110 | 65 |

| A | Dowel sleeves for centralising | |

| 1) Secures starter to gearbox 2) With bracket for wiring harness 3) Hammer head bolt with nut 4) With nut | ||

|

|

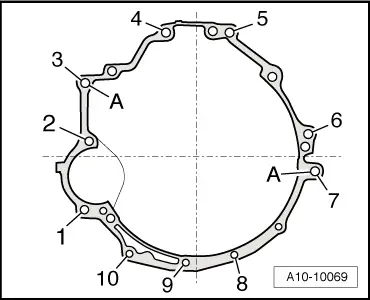

| Item | Bolt | Nm |

| 1 1) | M12 x 105 | 65 |

| 2 2) | M12 x 80 | 65 |

| 3 2) | M12 x 90 | 65 |

| 4 3) | M12 x 80 | 65 |

| 5, 7 | M12 x 95 | 65 |

| 6 3) | M12 x 105 | 65 |

| 8 4) | M10 x 50 | 45 |

| 9, 10, 11 | M10 x 45 | 45 |

| A | Dowel sleeves for centralising | |

| 1) With nut 2) Secures starter to gearbox 3) With bracket for wiring harness 4) Hammer head bolt with nut | ||

|

|

| Item | Bolt | Nm |

| 1, 10, 11 | M10 x 60 | 45 |

| 2 1) | M10 x 150 | 65 |

| 3 1) | M12 x 130 | 65 |

| 4 | M12 x 85 | 65 |

| 5, 6 | M12 x 90 | 65 |

| 7 | M10 x 100 | 45 |

| 8 | M12 x 95 | 65 |

| 9 2) | M10 x 60 | 45 |

| A | Dowel sleeves for centralising | |

| 1) Secures starter to gearbox 2) Hammer head bolt with nut | ||

|

|

| Item | Bolt | Nm |

| 1 1) | M12 x 140 | 65 |

| 2 1) | M12 x 155 | 65 |

| 3 | M12 x 110 | 65 |

| 4 | M12 x 115 | 65 |

| 5 | M12 x 110 | 65 |

| 6 | M12 x 125 | 65 |

| 7 2) | M10 x 160 | 65 |

| 8, 9, 10 | M10 x 80 | 45 |

| A | Dowel sleeves for centralising | |

| 1) Secures starter to gearbox 2) With nut | ||

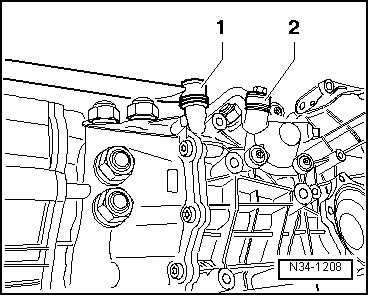

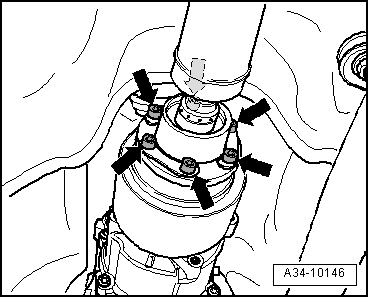

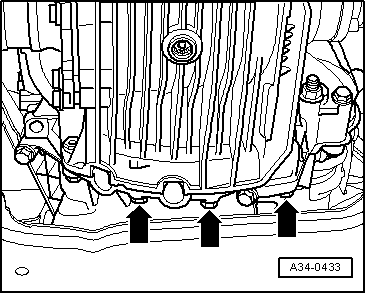

| Component | Nm | |

| Gearbox mounting to gearbox | 23 | |

| Heat shields above drive shafts to gearbox | 23 | |

| Heat shield for propshaft to gearbox cover | 25 | |

| Engine mounting to engine support | 23 | |

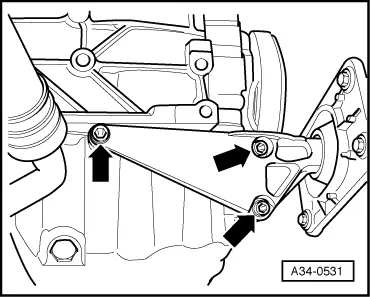

| Torque reaction support to engine (Cabriolet only) | 30 + 90° 1) | |

| Bracket for noise insulation to subframe | 10 | |

| 1) Renew bolt | ||

Caution

Caution