A4 Cabriolet Mk2

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

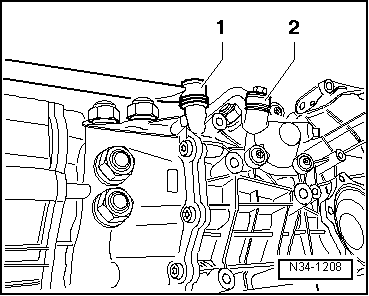

| Component | Nm | |

| Heat shield for drive shaft to gearbox | 23 | |

| Heat shield for propshaft to gearbox cover | 25 | |