A4 Cabriolet Mk2

| Removing gearbox on vehicles with 3.2 ltr. FSI engine |

| Special tools and workshop equipment required |

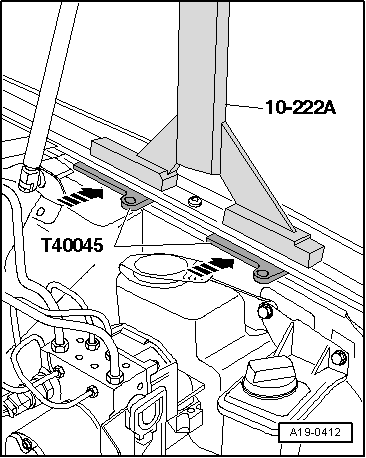

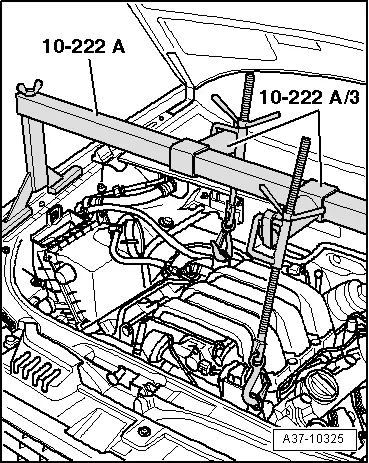

| t | Support bracket -10-222 A- |

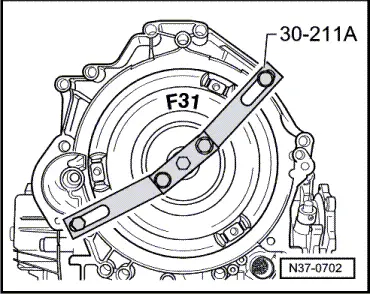

| t | Support bridge -30-211 A- |

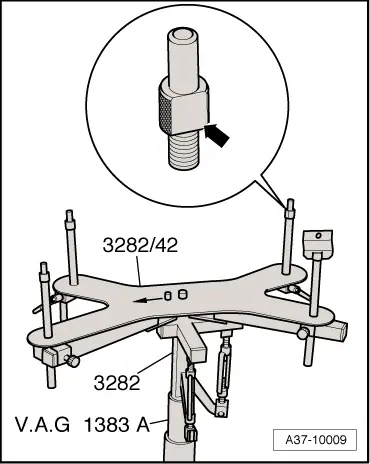

| t | Gearbox support -3282- |

| t | Adjustment plate -3282/48- |

| t | Pin -3282/50- |

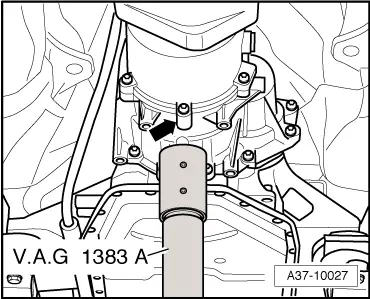

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Used oil collection and extraction unit -V.A.G 1782- |

| t | Wing compensation plate -T40045- |

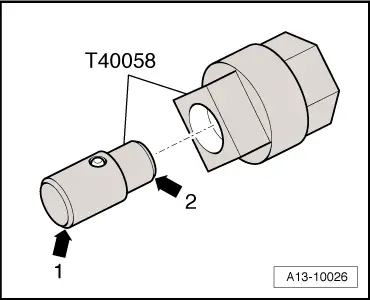

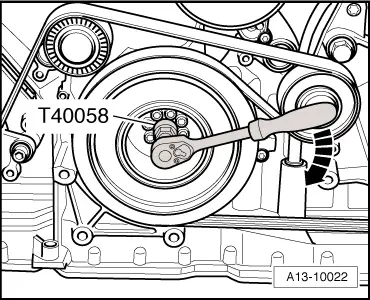

| t | Adapter -T40058- |

| t | Bolt M10x20 |

Note

Note

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note |

|

Note

Note

|

|

Note

Note |

|

Note

Note

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Caution

Caution WARNING

WARNING