A4 Cabriolet Mk2

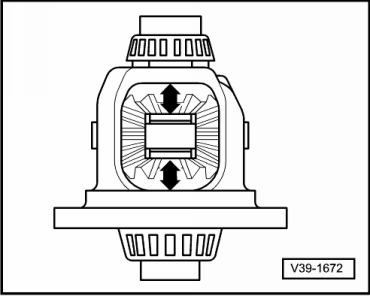

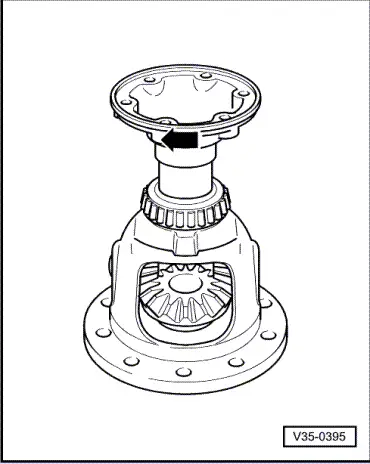

| Exploded view - dismantling and assembling differential |

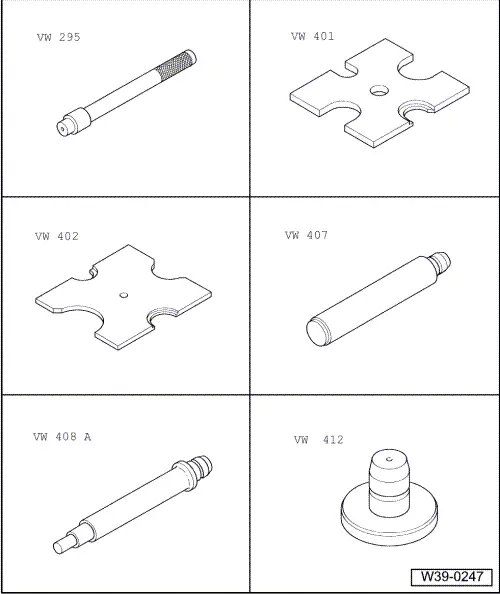

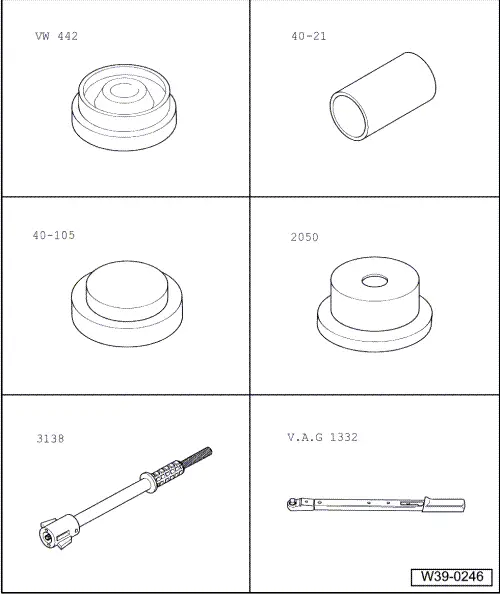

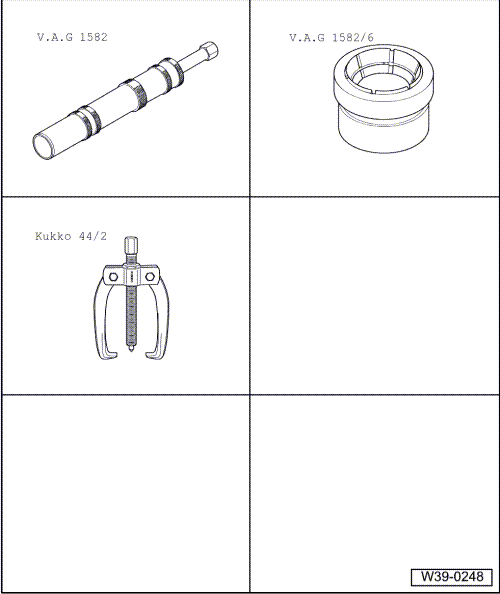

| Special tools and workshop equipment required |

| t | Drift -VW 295- |

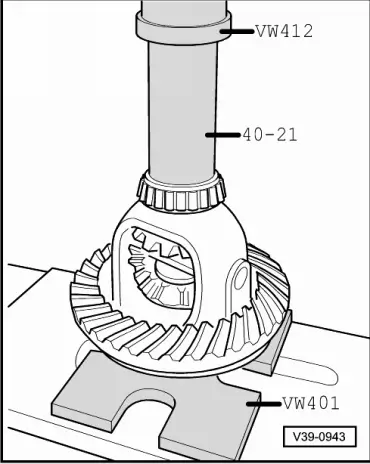

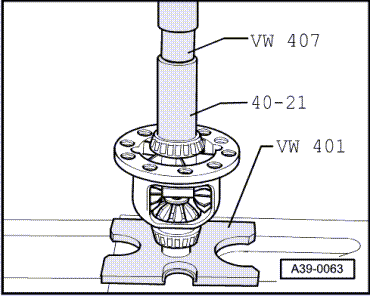

| t | Thrust plate -VW 401- |

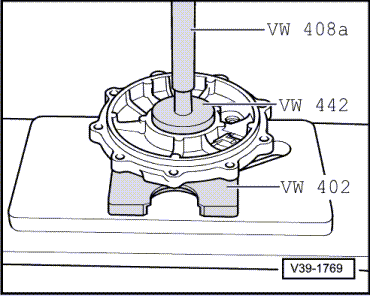

| t | Thrust plate -VW 402- |

| t | Press tool -VW 407- |

| t | Press tool -VW 408 A- |

| t | Press tool -VW 412- |

| t | Press tool -VW 442- |

| t | Press tool -40-21- |

| t | Thrust plate -40-105- |

| t | Thrust piece -2050- |

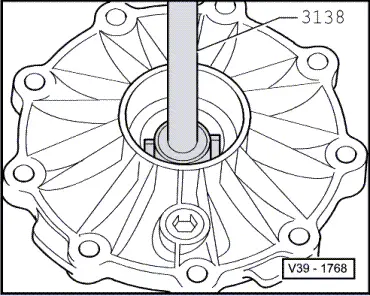

| t | Drift -3138- |

| t | Torque wrench -V.A.G 1332- |

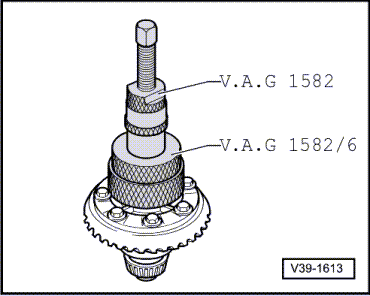

| t | Tapered roller bearing puller -V.A.G 1582- |

| t | Adapter -V.A.G 1582/6- |

| t | Puller -Kukko 44/2- |

| Heat tapered roller bearing inner races to 100°C before installing. |

| Always renew both tapered roller bearings together. |

| The differential must be adjusted → Chapter if the tapered roller bearings, differential cage, rear final drive cover, final drive gear set or the final drive housing are renewed. |

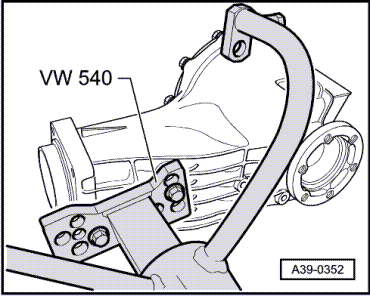

| Clamp rear final drive in assembly stand → Fig. |

| 1) | Adjustment work is required if these components are renewed → Chapter |

| 1 - | Cover for rear final drive → Note |

| 2 - | O-ring |

| q | Always renew |

| q | Lubricate with oil when installing |

| 3 - | Rear final drive housing → Note |

| 4 - | Shim S1 |

| q | Note thickness |

| q | Table of adjustments → Chapter |

| 5 - | Small tapered roller bearing outer race → Note |

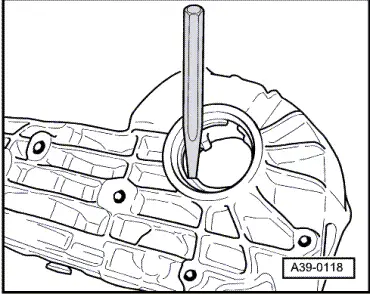

| q | Driving out → Fig. |

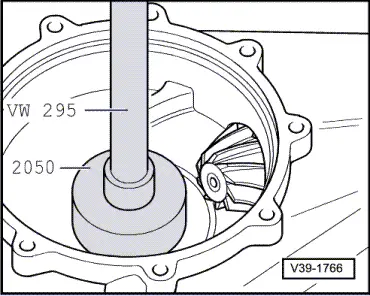

| q | Pressing in → Fig. |

| 6 - | Small tapered roller bearing inner race → Note |

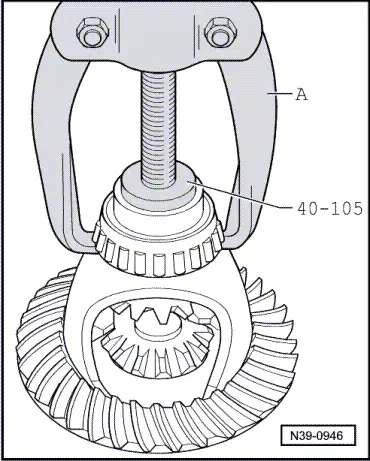

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 7 - | Hexagon bolt, 60 Nm then turn 45° further |

| q | Always renew |

| q | Lightly tighten bolts then tighten in diagonal sequence to correct torque |

| q | For correct version, refer to → Electronic parts catalogue |

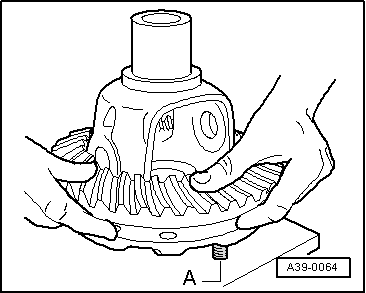

| 8 - | Differential cage → Note |

| 9 - | Crown wheel → Note |

| q | Is paired with pinion shaft (final drive gear set) |

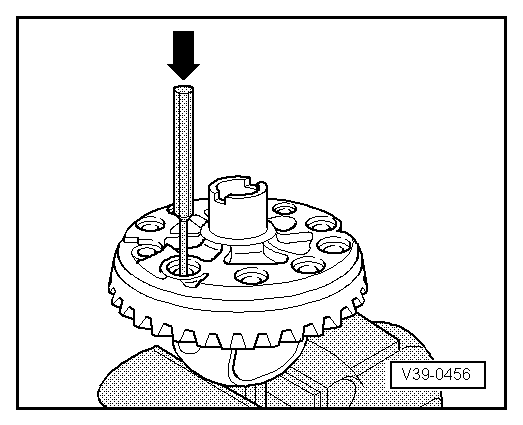

| q | Drive off with a drift → Fig. |

| q | Fitting on differential cage → Fig. |

| q | For correct version, refer to → Electronic parts catalogue |

| 10 - | Spring pin |

| q | For securing differential pinion pin |

| q | Drive in flush |

| 11 - | Large tapered roller bearing inner race → Note |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 12 - | Large tapered roller bearing outer race → Note |

| q | Driving out → Fig. |

| q | Pressing in → Fig. |

| 13 - | Shim S2 |

| q | Note thickness |

| q | Table of adjustments → Chapter |

| 14 - | Threaded piece |

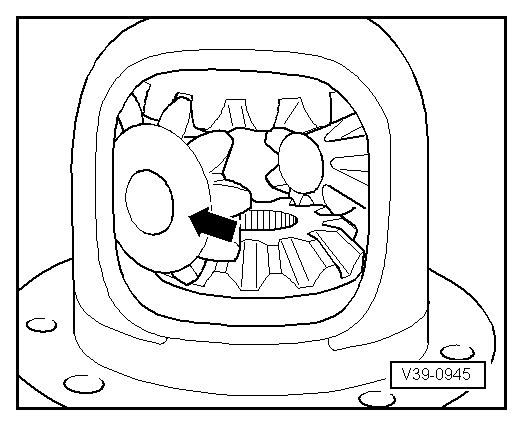

| 15 - | Sun wheel |

| q | Installing → Fig. |

| q | Adjusting → Fig. |

| 16 - | Planet pinion |

| q | Installing → Fig. |

| 17 - | Differential pinion pin |

| q | Drive out with drift |

| 18 - | Shim |

| q | Determining thickness → Fig. |

| 19 - | Thrust washer |

| q | Check for cracks |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Shim thickness (mm) | ||

| 0.50 | 0.70 | 0.90 |

| 0.60 | 0.80 | 1.00 |

|

|

|

WARNING

WARNING