| t

| When installing a new rear final drive unit, check the oil level in the final drive and top up if necessary → Chapter. |

| t

| When installing mounting brackets as well as other waxed components, the contact surfaces must be cleaned. The contact surfaces must be free of wax and grease. |

| t

| Thoroughly clean all joints and connections and the surrounding areas before dismantling. |

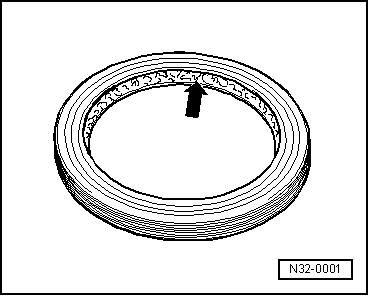

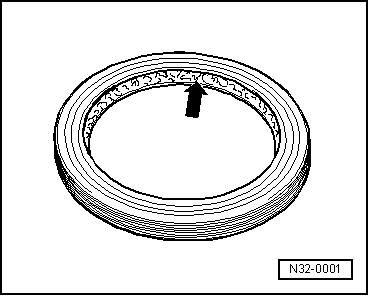

| O-rings, oil seals and gaskets |

| t

| Always renew O-rings, seals and gaskets. |

| t

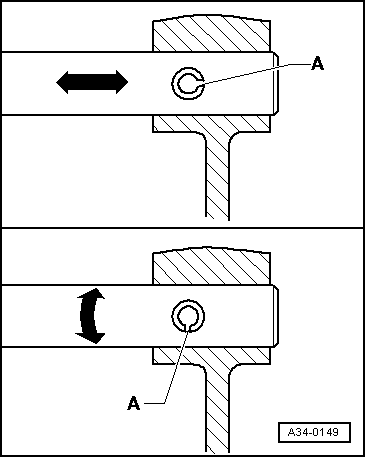

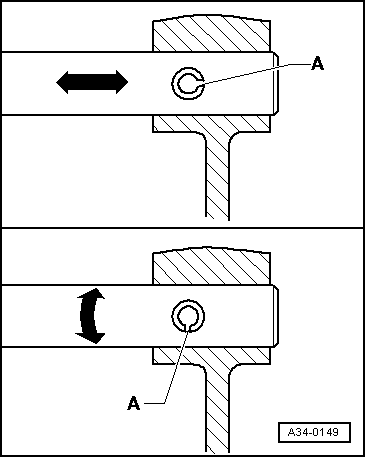

| After removing gaskets and seals, always inspect the contact surface on the housing or shaft for burrs resulting from removal or for other signs of damage. |

| t

| Thoroughly clean housing joint surfaces before assembling. |

|

|

|