A4 Cabriolet Mk2

| Dismantling and assembling pinion shaft |

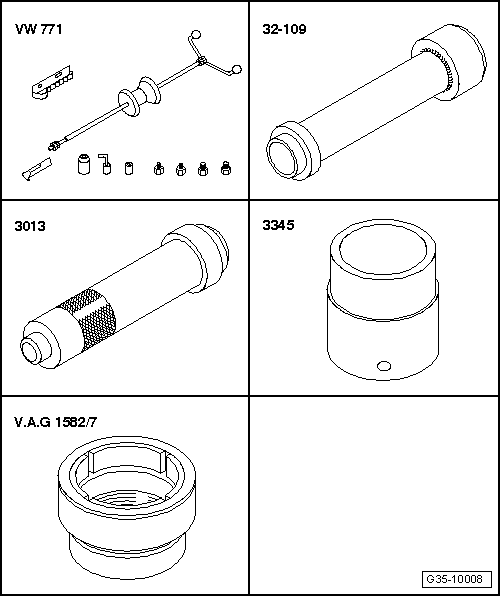

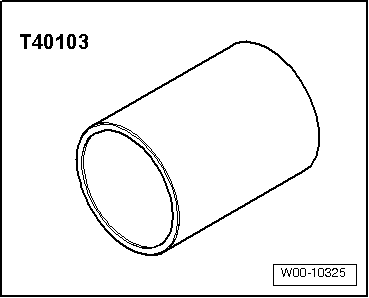

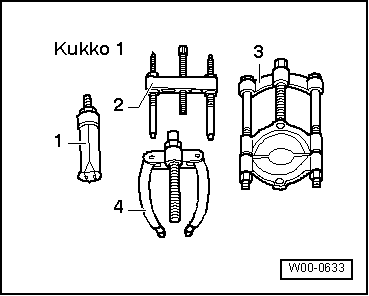

| Special tools and workshop equipment required |

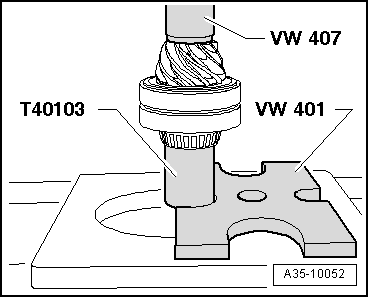

| t | Thrust plate -VW 401- |

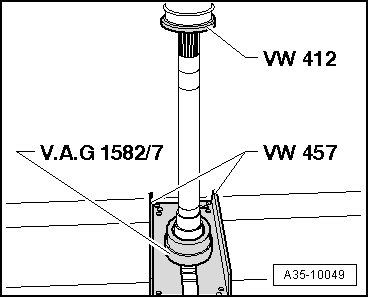

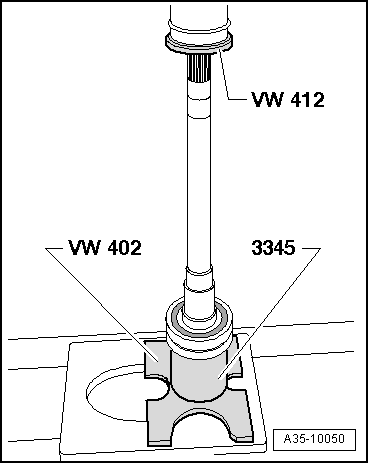

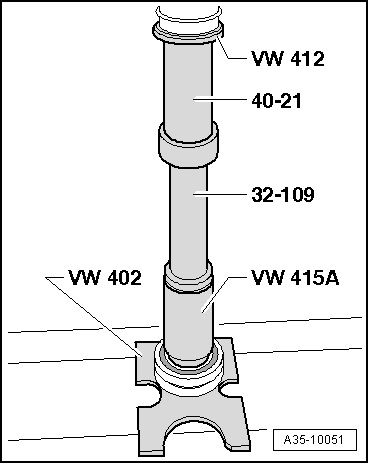

| t | Thrust plate -VW 402- |

| t | Press tool -VW 407- |

| t | Press tool -VW 412- |

| t | Tube -VW 415 A- |

| t | Support rails -VW 457- |

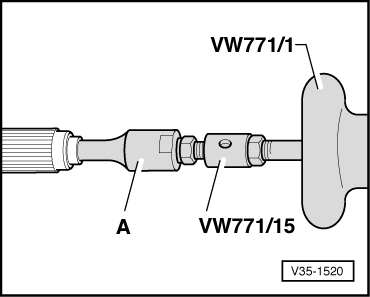

| t | Multi-purpose tool -VW 771- |

| t | Tube -32 - 109- |

| t | Drift sleeve -40 - 21- |

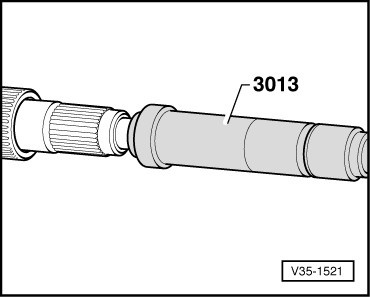

| t | Punch -3013- |

| t | Tube for wheel bearing -3345- |

| t | Adapter -V.A.G 1582/7- |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

| Circlip thickness (mm) | ||

| 1.50 | 1.90 | 2.30 |

| 1.55 | 1.95 | 2.35 |

| 1.60 | 2.00 | 2.40 |

| 1.65 | 2.05 | 2.45 |

| 1.70 | 2.10 | 2.50 |

| 1.75 | 2.15 | 2.55 |

| 1.80 | 2.20 | 2.60 |

| 1.85 | 2.25 | |