A4 Cabriolet Mk2

| ATF supply unit |

Caution

Caution

|

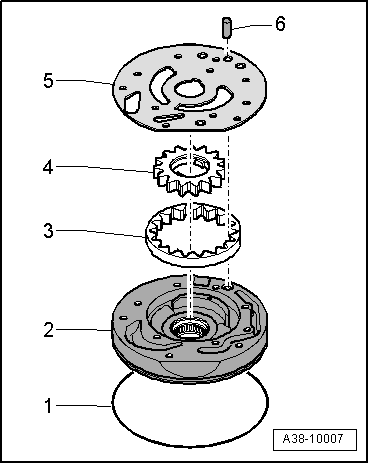

| 2 - | Corrugated washer |

| q | Check for distortion |

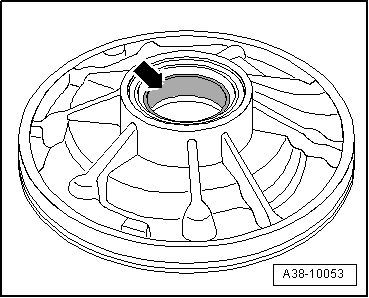

| 4 - | ATF pump housing |

| q | Check running surfaces for scoring and signs of abnormal wear → Fig. |

| q | Check brass bush for wear → Fig. |

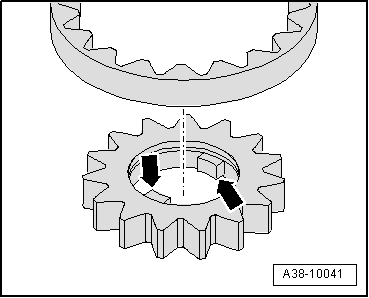

| 5 - | Annulus |

| q | Check running surfaces for scoring and signs of abnormal wear → Fig. |

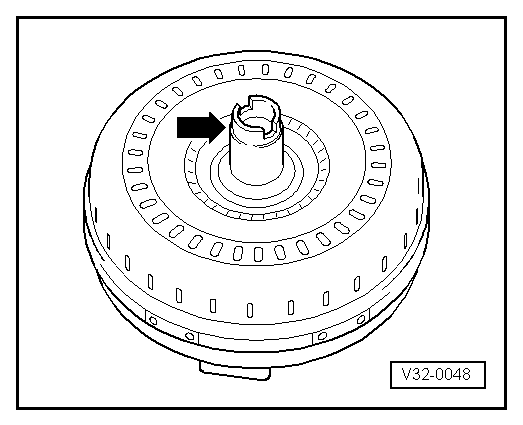

| 6 - | ATF pump gear |

| q | Check running surfaces for scoring and signs of abnormal wear → Fig. |

| q | Check drive lugs in ATF pump gear → Fig. |

| 8 - | Intermediate plate |

| q | Check running surfaces for scoring and signs of abnormal wear → Fig. |

| 10 - | ATF supply unit |

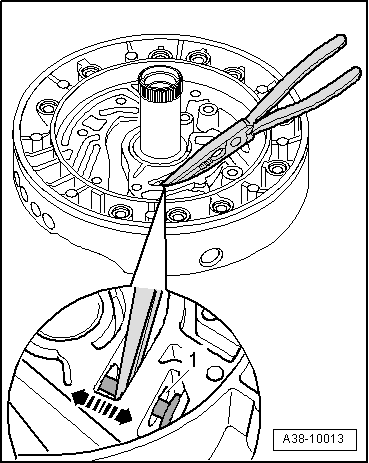

| q | Check that flow control valve of ATF supply unit moves freely → Fig. |

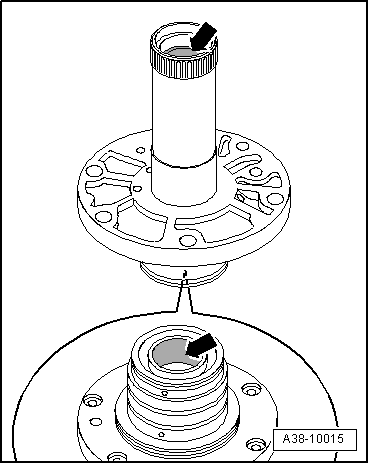

| 14 - | Stator shaft |

| q | Check brass bushes for wear → Fig. |

| q | Check splines for wear |

| q | Must be seated securely in housing of ATF supply unit → Item; renew both parts if loose |

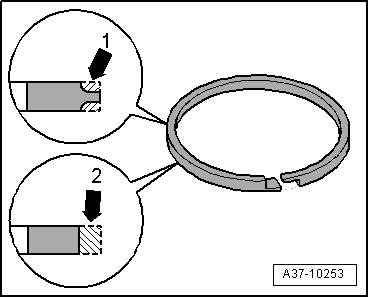

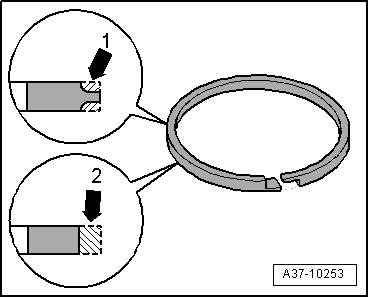

| 16 - | Rectangular section seals for clutch “B” |

| q | Checking for wear → Fig. |

| 17 - | Rectangular section seal for clutch “A” |

| q | Checking for wear → Fig. |

| 18 - | Axial needle bearing |

| q | Perform visual check for damage: axial needle bearing and contact surfaces should be in as-new condition; renew if necessary. |

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|