A4 Cabriolet Mk2

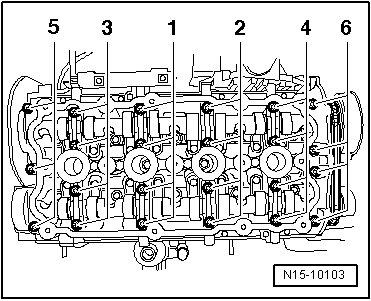

| Valve gear - exploded view |

| 1 - | 50 Nm + 180° |

| q | Renew |

| 2 - | Camshaft sprocket |

| 3 - | Oil seal |

| q | Renewing → Chapter |

| 4 - | Cylinder head |

| 5 - | Valve guide |

| q | Checking → Chapter |

| 6 - | Valve stem oil seal |

| q | Renewing with cylinder head installed → Chapter |

| q | Renewing with cylinder head removed → Chapter |

| 7 - | Valve spring |

| 8 - | Upper valve spring plate |

| 9 - | Cotters |

| 10 - | Hydraulic valve clearance compensation element |

| q | Do not interchange |

| q | Lubricate contact surface |

| 11 - | Parallel key |

| q | Check for firm attachment |

| 12 - | Exhaust camshaft |

| q | Check radial clearance with Plastigage (rocker fingers not installed). Wear limit: 0.1 mm |

| q | Runout: max. 0.035 mm |

| 13 - | Retaining frame |

| q | With integrated camshaft bearings |

| q | Clean sealing surface; machining not permitted |

| q | Remove old sealant residues |

| 14 - | Bolt |

| q | Renew |

| q | Tightening sequence → Fig. |

| 15 - | Camshaft adjuster |

| 16 - | 20 Nm + turn 45° further |

| q | Renew |

| 17 - | Inlet camshaft |

| q | Check radial clearance with Plastigage (rocker fingers not installed). Wear limit: 0.1 mm |

| q | Runout: max. 0.035 mm |

| 18 - | Chain tensioner |

| q | Remove → Chapter Removing and installing camshaft adjuster |

| q | Before removing, lock in place using locking pin -T10115- |

| 19 - | Drive chain |

| q | Check for wear |

| 20 - | 10 Nm |

| 21 - | 10 Nm |

| 22 - | Phase sensor |

| 23 - | Exhaust valve |

| q | Do not machine, only grinding-in is permitted |

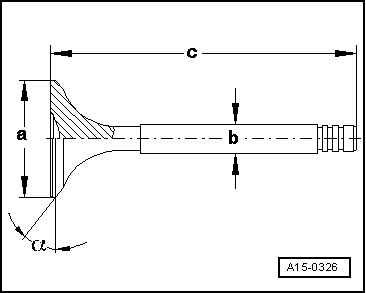

| q | Valve dimensions → Fig. |

| q | Checking valve guides → Chapter |

| 24 - | Inlet valve |

| q | Do not machine, only grinding-in is permitted |

| q | Valve dimensions → Fig. |

| q | Checking valve guides → Chapter |

| 25 - | Sealing cap |

| q | Renew |

| q | Removing sealing cap with retaining frame installed: pierce on one side with an awl and pry out |

| q | Installing: press in 1 ... 2 mm deep without sealant using thrust piece -3334- |

|

|

|

Note

Note

|

|

| Dimension | Inlet valve | Exhaust valve | |

| Ø a | mm | 33.85 ± 0.10 | 28.0 ± 0.1 |

| Ø b | mm | 5.98 ± 0.01 | 5.96 ± 0.01 |

| c | mm | 104.0 ± 0.2 | 101.9 ± 0.2 |

| α | ∠° | 45 | 45 |