A4 Cabriolet Mk2

| Cylinder head - exploded view |

| 1 - | Hall sender -G40- |

| q | For camshaft position |

| 2 - | 10 Nm |

| q | Apply locking fluid when installing; refer to → Electronic parts catalogue |

| 3 - | 15 Nm |

| 4 - | 100 Nm |

| q | Use counterhold tool -T10051- when loosening and tightening → Chapter „Removing and installing camshaft“ |

| 5 - | Hub |

| q | With sender wheel for Hall sender -G40- |

| q | To remove, use puller -T10052- → Chapter „Removing and installing camshaft“ |

| 6 - | Cylinder head bolt |

| q | Renew |

| q | Note correct sequence when loosening → Anchor |

| q | Note correct sequence when tightening → Anchor |

| q | Ensure that washers → Item are fitted in cylinder head |

| 7 - | Gasket for cylinder head cover |

| q | Renew if damaged or leaking |

| q | Only available together with cylinder head cover |

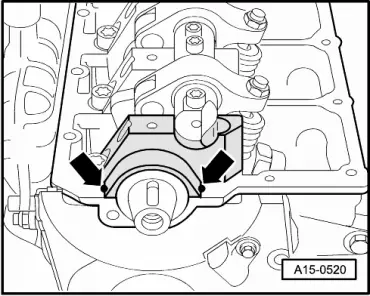

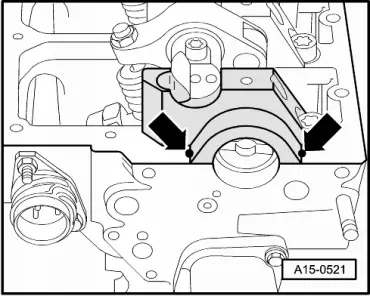

| q | Before fitting, apply sealant at sealing points → Fig. |

| q | Sealant → Electronic parts catalogue |

| q | Insert lugs into holes on cylinder head |

| 8 - | Crankcase breather hose |

| 9 - | Cap |

| 10 - | Seal |

| q | Renew if damaged or leaking |

| 11 - | Filler cap |

| 12 - | Special bolt, 10 Nm |

| q | Renew if damaged or leaking |

| q | Note correct sequence for loosening and tightening → Chapter „Removing and installing cylinder head cover“ |

| 13 - | Cylinder head cover |

| q | Removing and installing → Chapter |

| 14 - | Gasket |

| q | Renew |

| 15 - | Tandem pump |

| q | Removing and installing → Rep. Gr.20 |

| 16 - | M6 = 9 Nm; M8 = 22 Nm |

| 17 - | 9 Nm |

| 18 - | Connection |

| 19 - | Seal |

| q | Renew |

| 20 - | Cylinder head |

| q | Removing → Chapter |

Caution

Caution

|

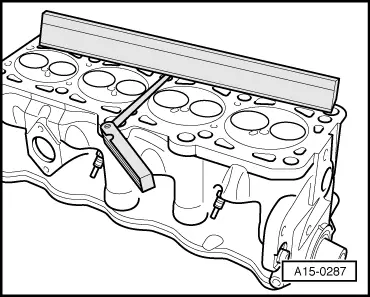

| q | Checking for distortion → Fig. |

| q | Installing → Anchor |

| q | If renewed, change coolant and engine oil |

| 21 - | Oil supply pipe |

| q | To turbocharger |

| 22 - | Banjo bolt, 25 Nm |

| 23 - | Seals |

| q | Renew |

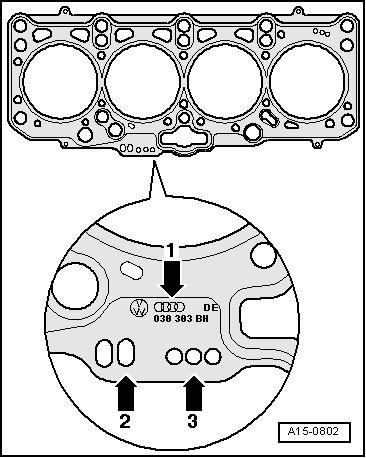

| 24 - | Cylinder head gasket |

| q | Renewing → Chapter „Removing and installing cylinder head“ |

| q | Note marking → Fig. |

| q | If renewed, change coolant and engine oil |

Note

Note

|

|

|

|

|

|