A4 Cabriolet Mk2

| Removing and installing sump (top section) |

| Special tools and workshop equipment required |

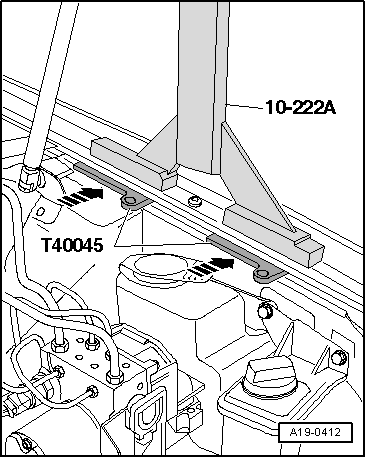

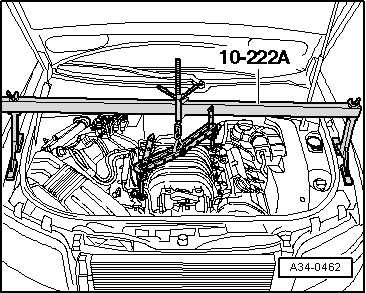

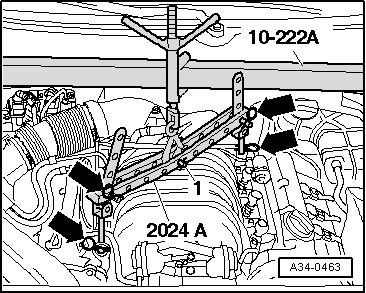

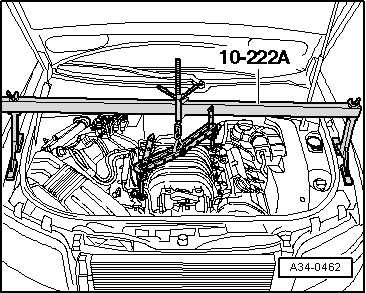

| t | Support bracket -10-222 A- |

| t | Lifting tackle -2024 A- |

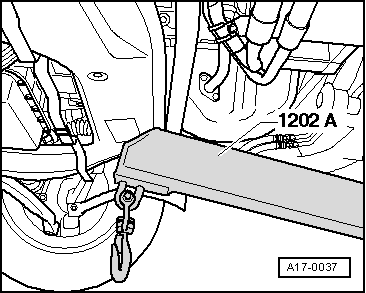

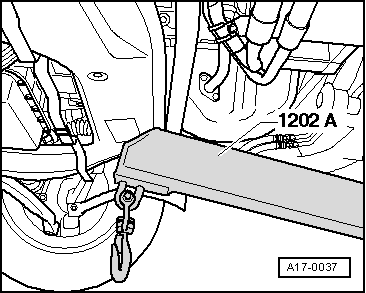

| t | Workshop hoist -VAS 6100- or -V.A.G 1202 A- |

| t | Drip tray for workshop hoist -VAS 6208- or -V.A.G 1306- |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

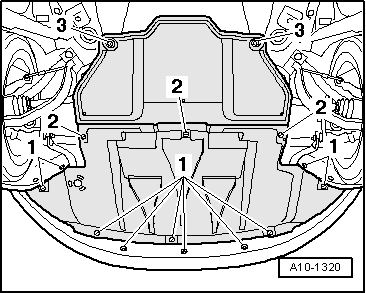

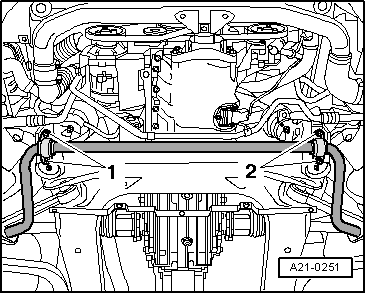

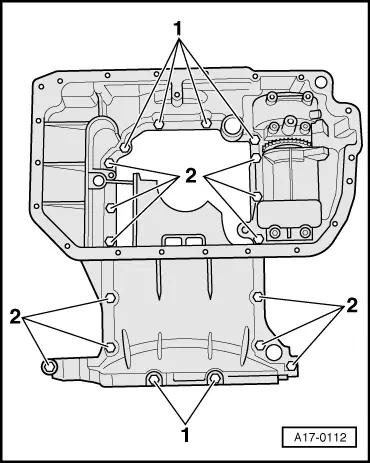

| Component | Nm | |

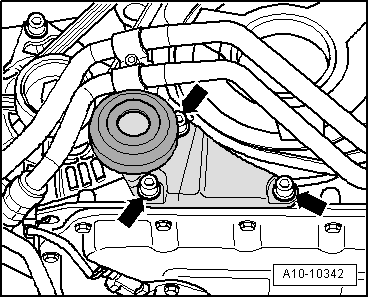

| Balance shaft housing to sump (top section) | 22 | |

| Sump (top section) to: | Cylinder block and sealing flanges | 16 |

| Gearbox | 45 → Note | |

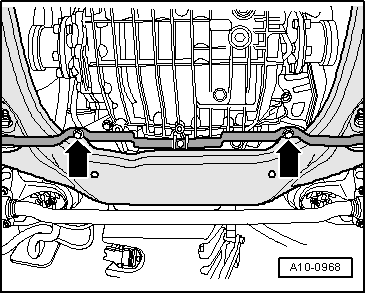

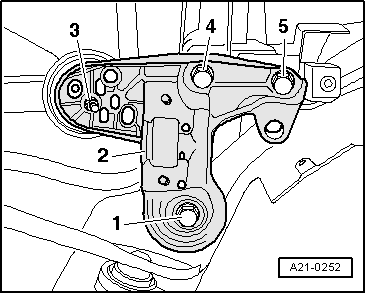

| Console for engine mounting to longitudinal member | 75 | |

| Engine mounting to console for engine mounting | 23 | |

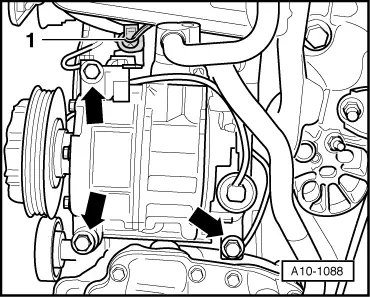

| Bracket for A/C compressor to: | Sump (top section) | 22 |

| Bracket for power steering pump and oil cooler | 22 | |

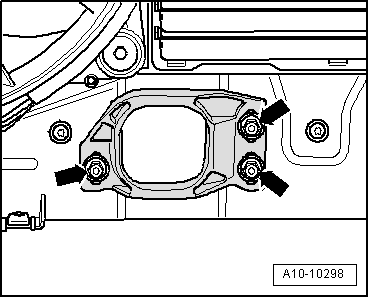

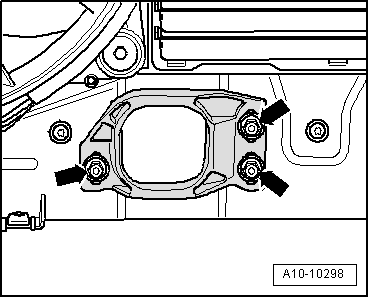

| Torque reaction support to top section of sump | 40 | |

| Stop for torque reaction support | 28 | |

|

Caution

Caution WARNING

WARNING