A4 Cabriolet Mk2

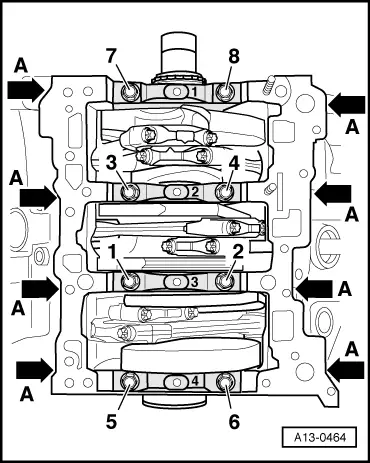

| Crankshaft - exploded view |

Note

Note| When carrying out repairs, secure engine to assembly stand with engine and gearbox support -VAS 6095- → Chapter. |

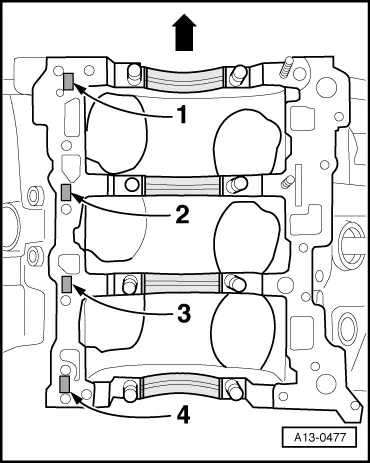

| 1 - | Bolt |

| q | For bearing cap |

| q | Renew |

| q | Tightening sequence → Fig. |

| 2 - | Dowel sleeve |

| q | Insert in cylinder block |

| 3 - | Drive chain sprocket for oil pump |

| q | Removing and installing → Chapter |

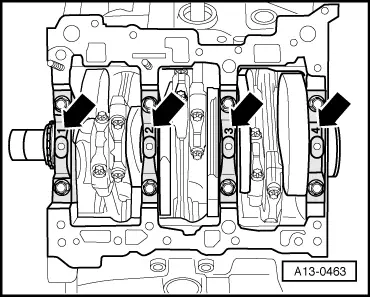

| 4 - | Bearing cap |

| q | Note marking → Fig. |

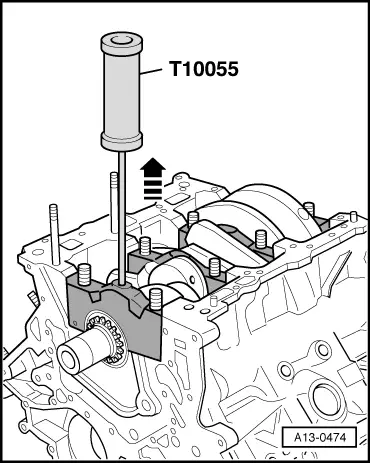

| q | Removing → Fig. |

| q | Installing → Fig. |

| 5 - | Nut |

| q | For bearing cap |

| q | Renew |

| q | Tightening sequence → Fig. |

| 6 - | Thrust washer |

| q | Only fitted on 4th crankshaft bearing |

| q | Oil grooves face outwards |

| q | Note location |

| q | Measuring axial clearance of crankshaft → Chapter |

| 7 - | Bearing shell |

| q | For bearing cap (without oil groove) |

| q | Do not interchange used bearing shells (mark positions) |

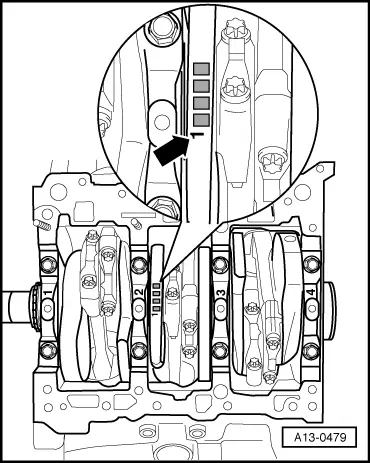

| q | Install new bearing shells for the bearing caps with the correct coloured markings → Fig. |

| 8 - | Crankshaft |

| q | Measuring axial clearance → Chapter |

| q | Measuring radial clearance → Chapter |

| q | Do not rotate the crankshaft when checking the radial clearance |

| q | Crankshaft dimensions → Chapter |

| 9 - | Thrust washer |

| q | Only fitted on 4th crankshaft bearing |

| q | Oil grooves face outwards |

| q | Measuring axial clearance of crankshaft → Chapter |

| 10 - | Bearing shell |

| q | For cylinder block (with oil groove) |

| q | Do not interchange used bearing shells (mark positions) |

| q | Install new bearing shells for the bearing caps with the correct coloured markings → Fig. |

| 11 - | Stud |

| 12 - | Bolt |

| q | For bearing cap |

| q | Renew |

| q | Tightening sequence → Fig. |

|

|

|

|

| Letter on cylinder block | Colour coding of bearing | |

| G | = | Yellow |

| B | = | Blue |

| S | = | Black |

|

|

| Letter on crankshaft | Colour coding of bearing | |

| G | = | Yellow |

| B | = | Blue |

| S | = | Black |

|

|