A4 Cabriolet Mk2

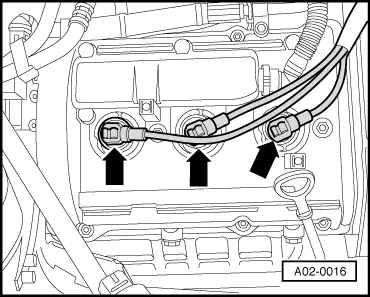

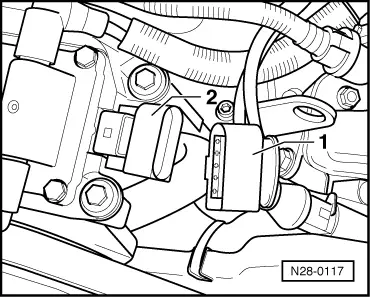

| Checking compression |

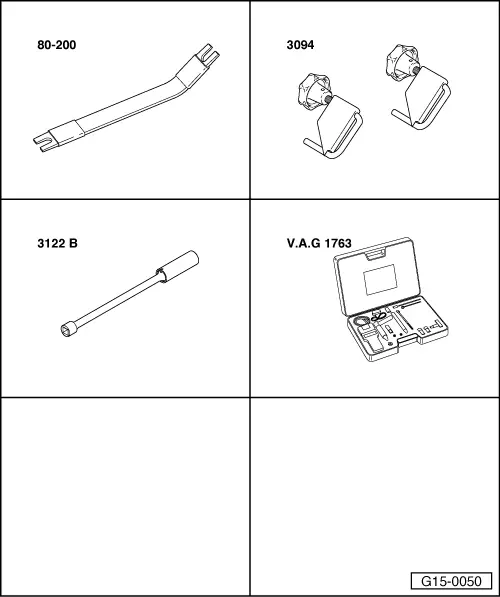

| Special tools and workshop equipment required |

| t | Removal lever -80-200- |

| t | Hose clamps for hoses up to 25 mm Ø -3094- |

| t | Spark plug socket and extension -3122 B- |

| t | Compression tester -V.A.G 1763- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

| New pressure in bar | Wear limit bar | Permissible difference between cylinders bar |

| 9.0 … 14.0 | 7.5 | 3.0 (maximum) |

|

| Component | Nm |

| Spark plugs in cylinder head | 30 |