A4 Cabriolet Mk2

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

| Component | Nm | |

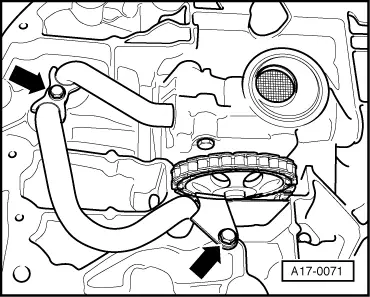

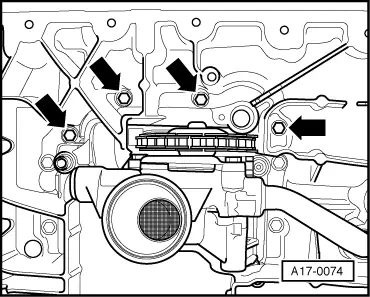

| Brackets for oil pipes to sump (top section) | 10 | |

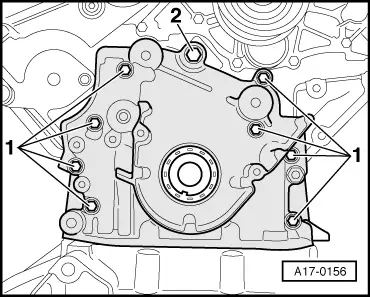

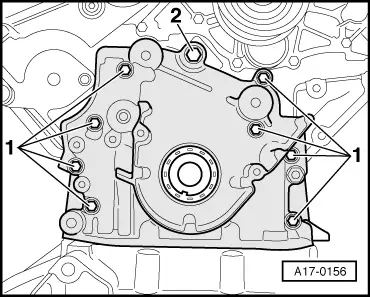

| Sealing flange (front) | M6 | 10 |

| to cylinder block | M8 | 30 → Note |

| Sealing flange (front) to sump (top section) | 16 | |

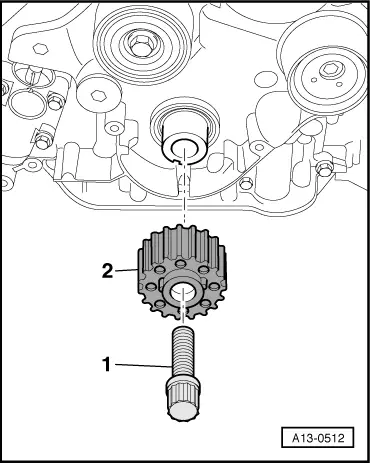

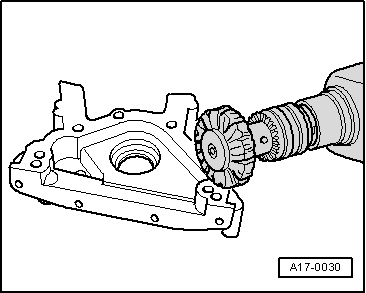

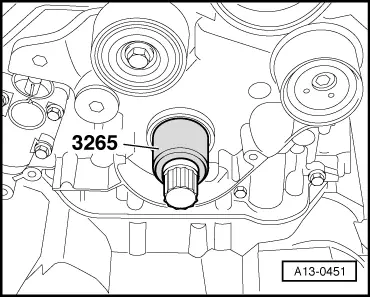

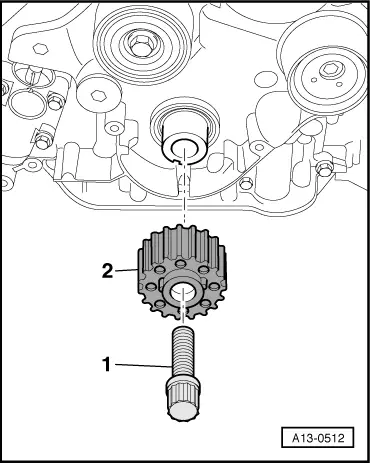

| Toothed belt sprocket to crankshaft | 200 + 180° → Note → Note | |

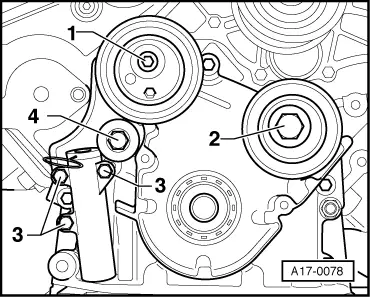

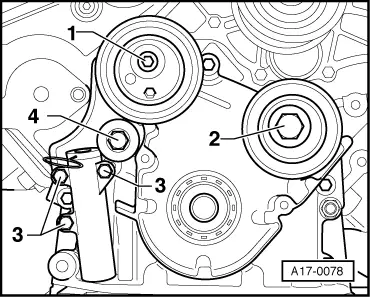

| Tensioner to sealing flange (front) | 10 | |

| Tensioning lever to sealing flange (front) | 22 | |

| Tensioning roller to sealing flange (front) | 22 | |

| Idler roller to sealing flange (front) | 43 | |

|

WARNING

WARNING