A4 Cabriolet Mk2

|

|

|

Note

Note

|

|

Note

Note

|

|

| Component | Nm | |

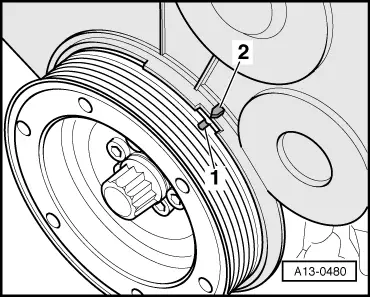

| Flywheel to crankshaft | ||

| Bolt length 22.5 mm | 60 + 90° → Note → Note | |

| 35.0 mm | 60 + 180° → Note → Note | |

| 43.0 mm | 60 + 180° → Note → Note | |

| Sealing plug in cylinder block | 10 | |

|

Caution

Caution WARNING

WARNING