| –

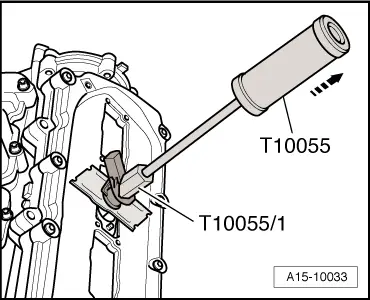

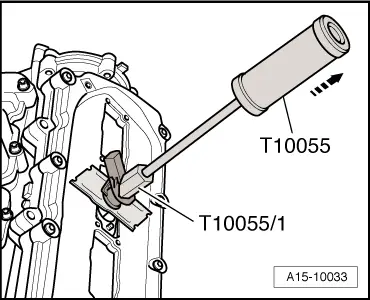

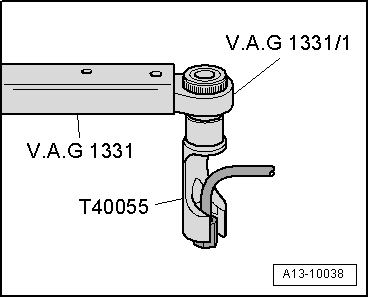

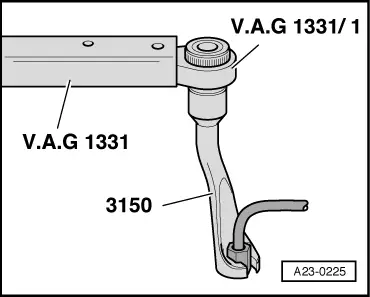

| Pull out injectors using puller -T10055- with adapter -T10055/1-. |

| –

| After removal, lay injectors on a clean cloth. |

| Important instructions for installing injectors: |

| l

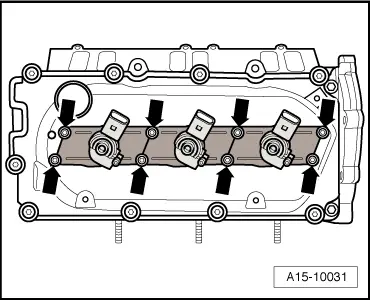

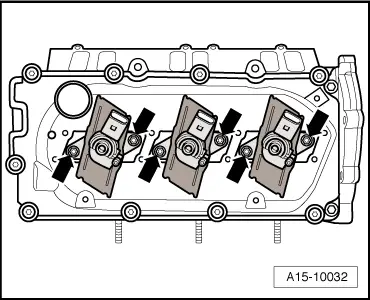

| When removing and installing, always renew the following components and seals/O-rings: „copper seal“, „O-ring for injector bore“, „O-ring for injector return connection“. |

| l

| The following components and seals/O-rings must always be renewed when an injector is renewed: „clamping piece“, „copper seal“, „O-ring for injector bore“, „O-ring for injector return connection“ |

| l

| Used injectors and high-pressure pipes may only be re-installed on the same cylinders. |

| l

| Make sure that the injectors and the surrounding areas are clean before installing. |

| l

| The injectors must be completely undamaged. |

| l

| Lubricate all O-rings with engine oil or assembly oil before installing. |

Note | t

| Note identification marks for cylinder allocation when re-installing high-pressure pipes. |

| t

| The high-pressure pipes can be re-used after performing the following checks: |

| t

| Check taper seats of high-pressure pipes for deformation and cracks. |

| t

| The bore of the pipe must not be distorted, restricted or otherwise damaged. |

| t

| Corroded pipes must not be used again. |

| If a used injector is being re-installed: |

| –

| Spray tip of injector nozzle with rust-releasing spray. Wait approx. 5 minutes and wipe off soot particles and oil with a cloth. |

| –

| If an injector is very dirty, the tip of the nozzle should also be cleaned with a soft brass wire brush to make it easier to remove the copper seal. Do not apply the wire brush to the bores in the nozzle. |

| –

| To remove the old copper seal from the injector, clamp the seal carefully in a vice so that it is just held between the jaws without turning. Then carefully pull and twist the injector out of the copper seal by hand. |

| –

| Clean off deposits under the copper seal using a suitable scraper. |

| –

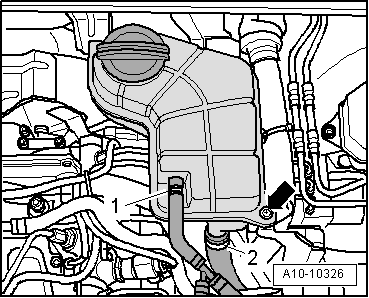

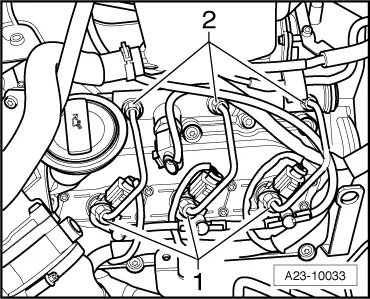

| Renew O-rings -2- at all return line connections. |

Note | Lubricate all seals with engine oil or assembly oil before installing. |

| –

| To remove carbon deposits from the injector sealing surface, clean the injector seat in the cylinder head with a cloth soaked in engine oil or rust solvent. Take care not to damage the sealing surface. |

Note | t

| Note identification marks for cylinder allocation when re-installing high-pressure pipes. |

| t

| The high-pressure pipes can be re-used after performing the following checks: |

| t

| Check taper seats of high-pressure pipes for deformation and cracks. |

| t

| The bore of the pipe must not be distorted, restricted or otherwise damaged. |

| t

| Corroded pipes must not be used again. |

| t

| Lubricate threads of union nuts with fuel. |

| –

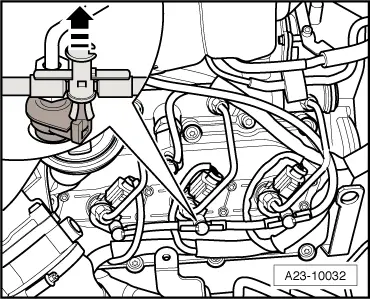

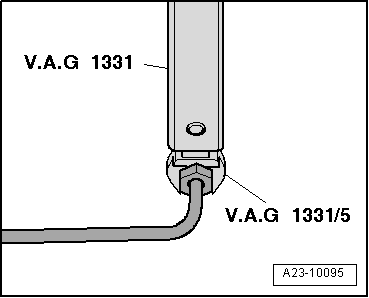

| Hand-tighten union nuts on high-pressure pipes. Make sure that connections are not under tension. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note Note

Note

Note

Note Note

Note Note

Note

Caution

Caution