| –

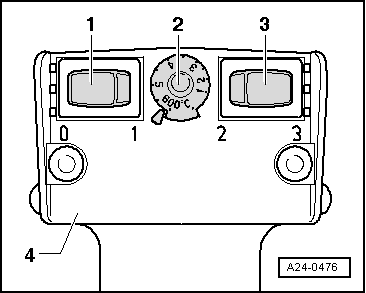

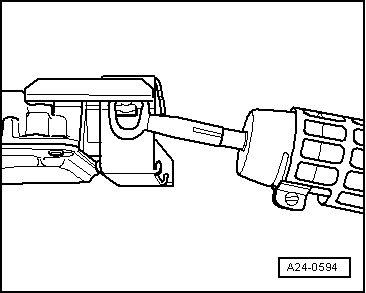

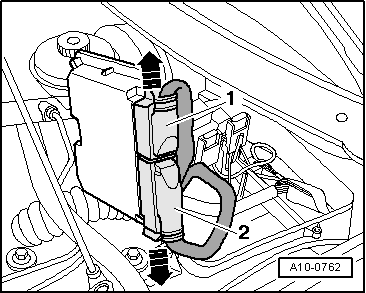

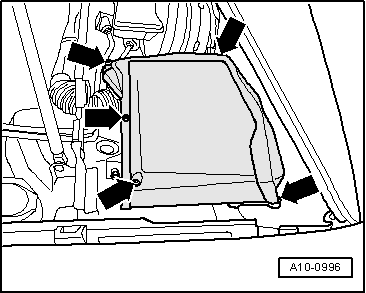

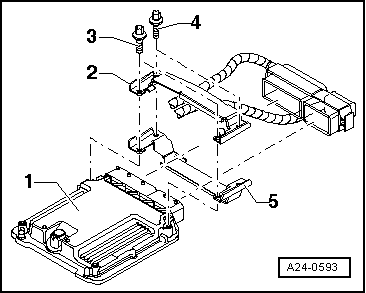

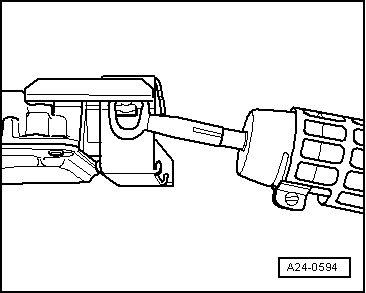

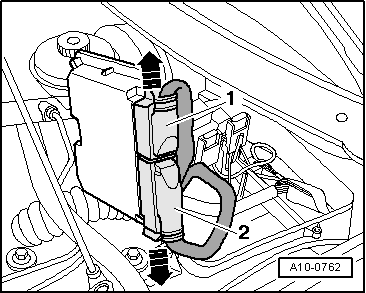

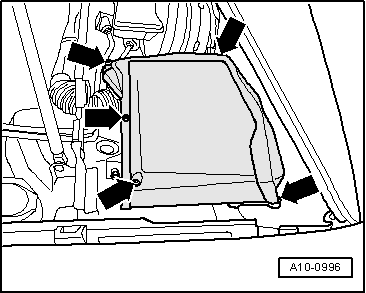

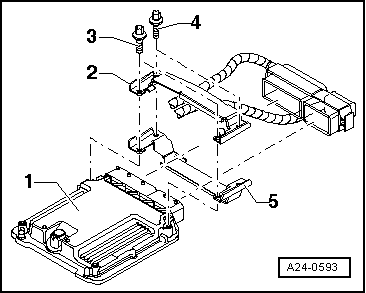

| Release retaining tabs -arrows- and unplug connectors -1 and 2- from engine control unit. |

| –

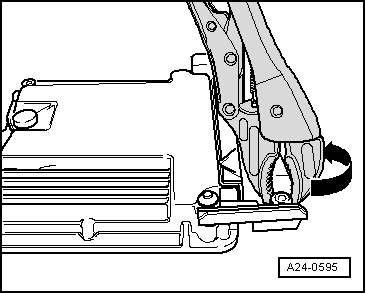

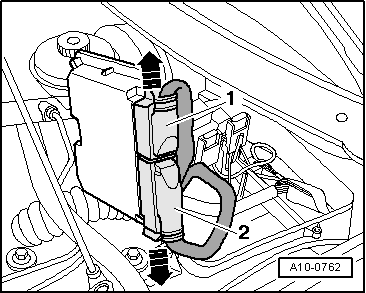

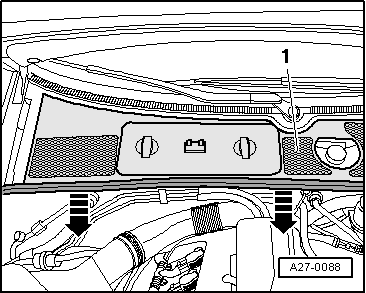

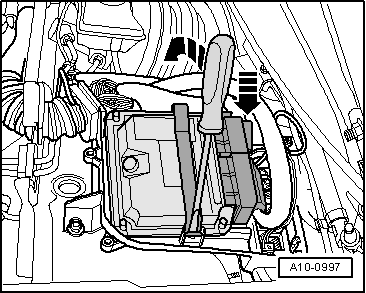

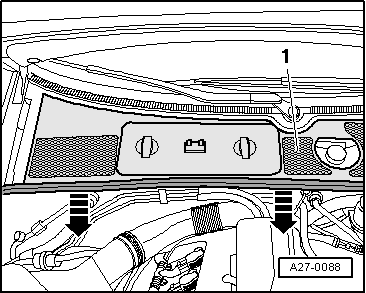

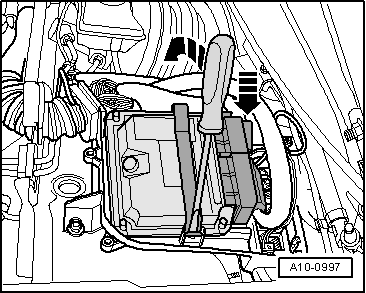

| Take out old engine control unit -J623- and install new engine control unit -J623-. |

| Installation is performed in the reverse sequence. |

| –

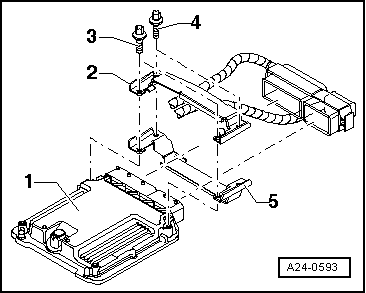

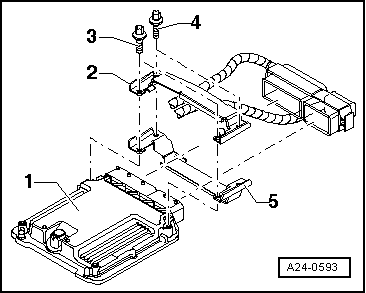

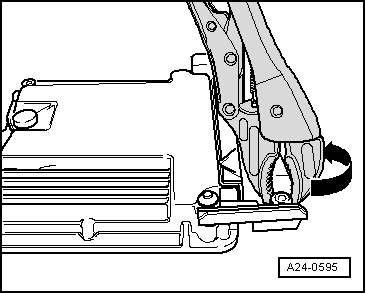

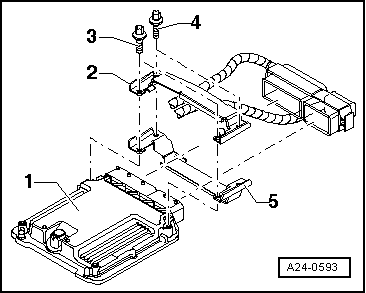

| After installation, the locking plate must be re-fitted on the engine control unit -J623-. |

| –

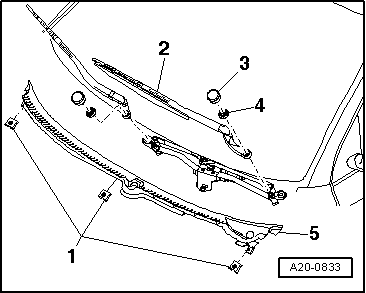

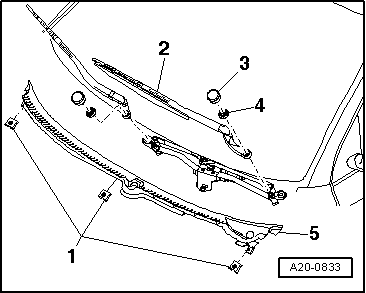

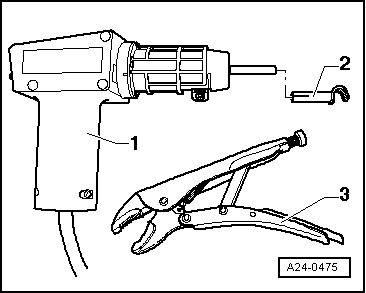

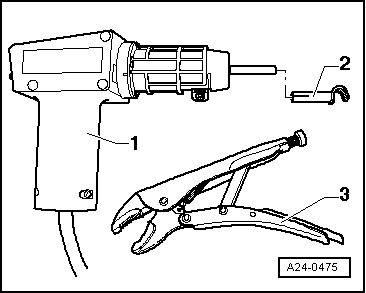

| Clean threaded holes for shear bolts to remove any residue from locking fluid. This can be done using a thread tap. |

| –

| Always use new shear bolts. |

| The procedure required after connecting the new engine control unit is described in the Guided Fault Finding or Guided Functions. |

| –

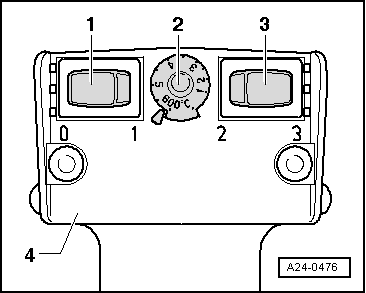

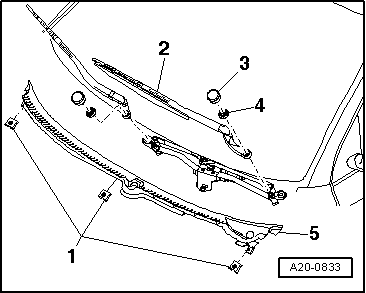

| Activate engine control unit on vehicle diagnosis and service information system -VAS 5052- in „Guided Functions“ mode, „J623 - Renew engine control unit, further steps“. |

| –

| The injector delivery calibration and the injector voltage calibration must additionally be re-adapted in the engine control unit -J623- after the control unit has been renewed (these functions influence engine power and exhaust emissions). |

| –

| On vehicles with particulate filter the current mileage (km) reading must be stored in the engine control unit via an adaption procedure. |

|

|

|

Note

Note

Note

Note