WARNING | t

| Always read rules for cleanliness and instructions for working on fuel system → Chapter. |

| t

| Follow these instructions and rules for cleanliness before starting work and while working on the fuel system. |

|

| –

| Erase fault memory of engine control unit. |

| –

| Clean all connections (with commercial cleaning solution etc.) before removing. |

Note | t

| Make sure all parts are clean; no dirt must be allowed to enter the fuel system. |

| t

| Check all cylinders in turn. |

| –

| Dry all components after cleaning. |

| –

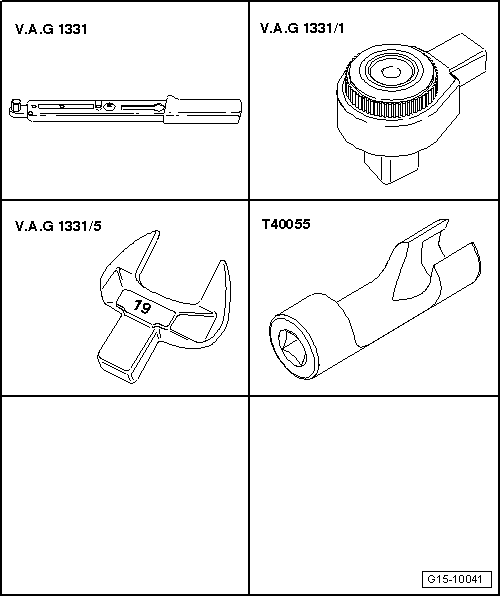

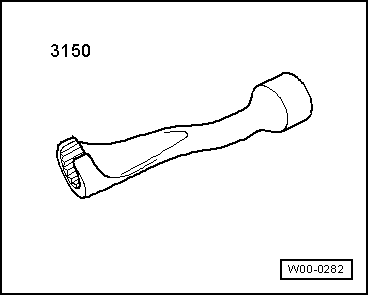

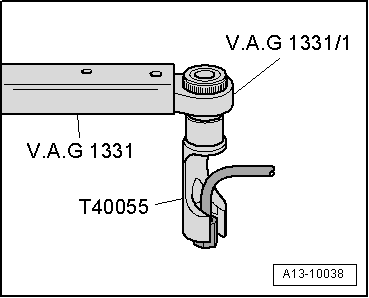

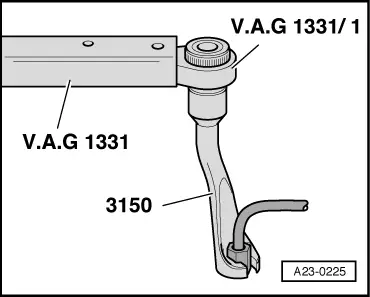

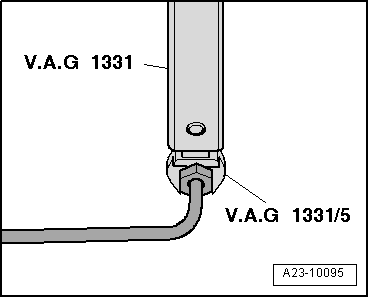

| Using socket, 14 mm -3150- or tool insert, AF 19 -V.A.G 1331/5-, unscrew union nut for No. 1 cylinder at rail element. Also loosen union nut on injector slightly using socket -T40055-, 17 mm. Seal off open connection on injector pipe. |

| –

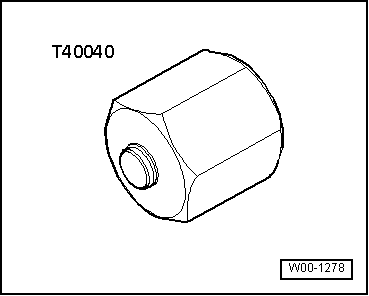

| Seal off open connection on rail element using plug for rail connection -T 40040-. |

| –

| The electrical connector of the relevant injector must remain connected. |

Note | t

| The fault „positive control deviation“ should no longer be indicated when the defective injector has been located. |

| t

| Other fault messages may possibly be stored in the memory. These result from previous steps and can be disregarded. |

| –

| Interrogate fault memory after road-testing vehicle. If a fault relating to „positive control deviation“ is still being indicated, repeat the above steps for all rail element connections until the fault is no longer indicated after the road-test. |

| Observe all instructions for connecting injector pipes. |

Note | t

| Note identification marks for cylinder allocation when re-installing high-pressure pipes. |

| t

| The high-pressure pipes can be re-used after performing the following checks: |

| t

| Check taper seats of high-pressure pipes for deformation and cracks. |

| t

| The bore of the pipe must not be distorted, restricted or otherwise damaged. |

| t

| Corroded pipes must not be used again. |

| –

| Lubricate threads of union nuts with fuel. |

| –

| Hand-tighten union nuts on high-pressure pipes. Make sure that connections are not under tension. |

|

|

|

Note

Note Note

Note Note

Note

WARNING

WARNING