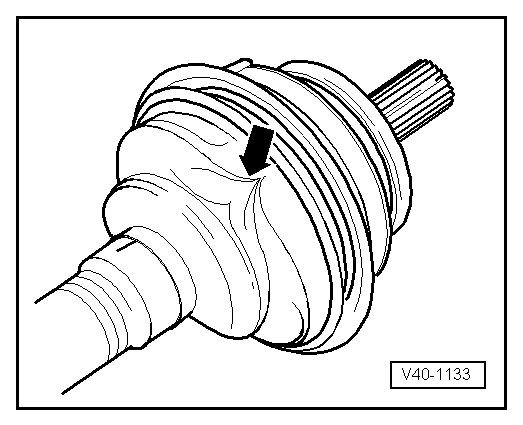

| Only applies to boots made of rubber: |

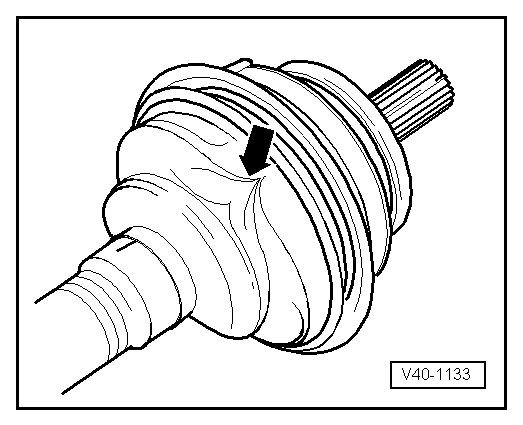

| A partial vacuum is sometimes created in the rubber boot during installation. |

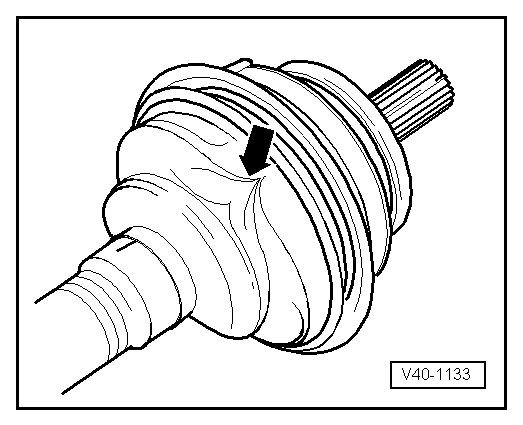

| This vacuum produces a fold -arrow- when driving. |

| For this reason, please note the following: |

| –

| Before tightening the hose clips, vent the boot to equalise pressure by briefly lifting the lip. |

|

|

|