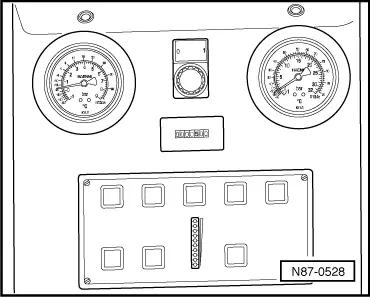

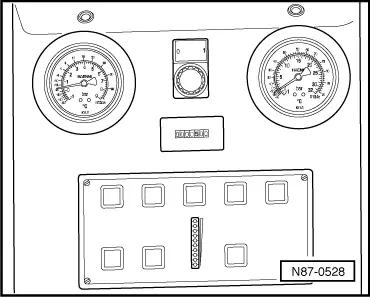

| Evacuating refrigerant circuit with air conditioner service station |

| l

| The work procedure must always be performed as described in the operating instructions of the air conditioner service station. |

| l

| Quantity of refrigerant oil in refrigerant circuit checked and if necessary corrected → Chapter. |

| l

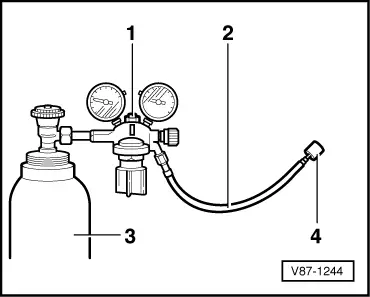

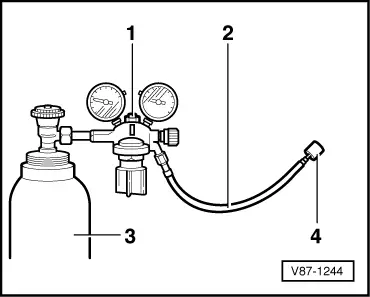

| Quantity of refrigerant in air conditioner service station checked |

| The refrigerant circuit must be evacuated before it is filled with refrigerant. In addition, moisture is removed from the circuit. |

| Leaks can be detected on evacuating the refrigerant circuit. |

Caution | t

| Do not start the engine during the evacuating procedure and while there is a vacuum in the refrigerant circuit. |

| t

| The air conditioner compressor may be damaged if the engine is started whilst there is a vacuum in the refrigerant circuit. |

| t

| Always charge the refrigerant circuit before starting the engine. |

|

| –

| Connect air conditioner service station to power supply. |

| –

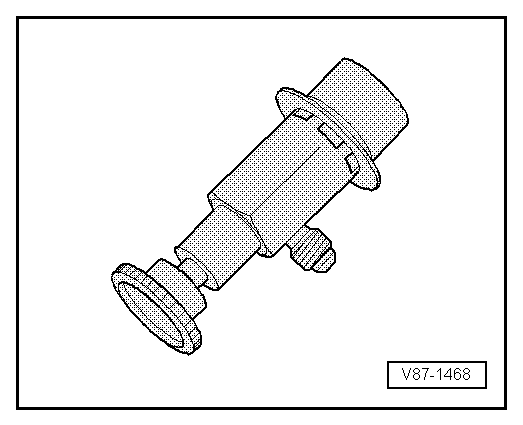

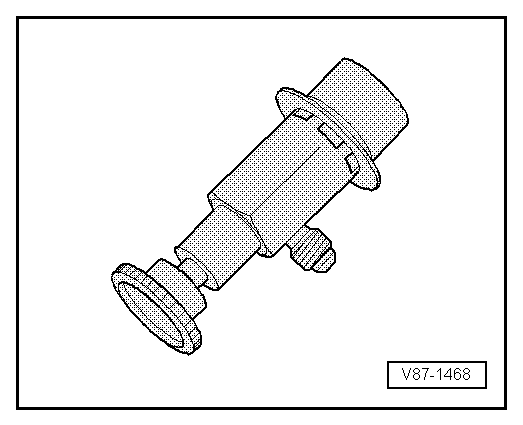

| Screw in the handwheel of the quick-release coupling adapters to the extent required to reliably open the valves of the service connections (take care not to open the valve too far). |

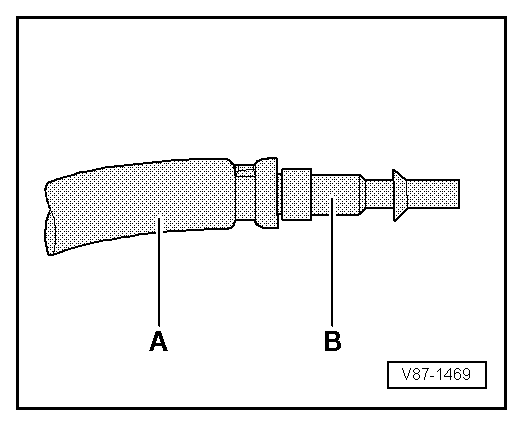

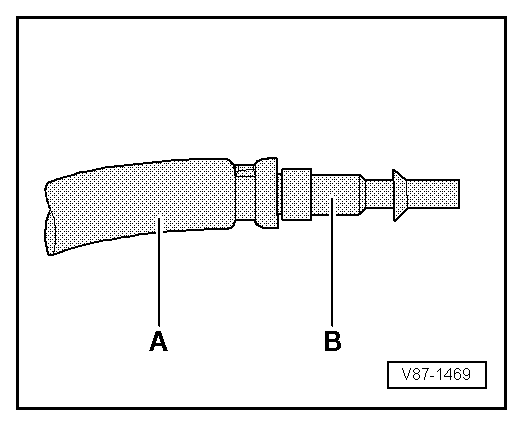

Note | If you intend to measured the pressure on only one side of the refrigerant circuit after charging the system (on vehicles with a service connection), use the valve adapter and filler hose with valve opener → Chapter. |

| –

| Switch on air conditioner service station and evacuate refrigerant circuit for at least 30 minutes. In this process, the pressure reading must be less than 10 mbar absolute (corresponding to a vacuum of 990 mbar). |

Note | On the air conditioner service station V.A.G 1885 (for currently available air conditioner service stations, refer to → V.A.G workshop equipment catalogue), the two green LEDs light at this pressure for example. |

| –

| Switch off the air conditioner service station and allow to stand for at least 1 hour. |

| l

| If the vacuum display (LED chain) does not change, the system is free of leaks and can be charged. |

Note | t

| With V.A.G 1885 for example (for currently available air conditioner service stations, refer to → V.A.G workshop equipment catalogue), a current vacuum display (LED) is only obtained after pressing the Evacuation button again. |

|

|

|

Note

Note Note

Note Note

Note Note

Note

Note

Note Note

Note Note

Note Note

Note