A4 Mk1

|

Removing and installing gearbox

Removing

|

|

|

|

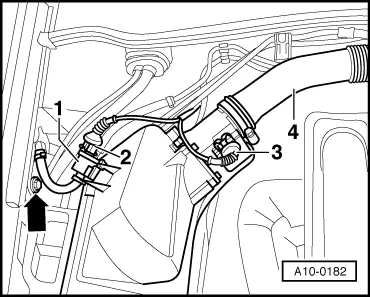

Vehicles with 4-cylinder normally aspirated engine:

|

|

|

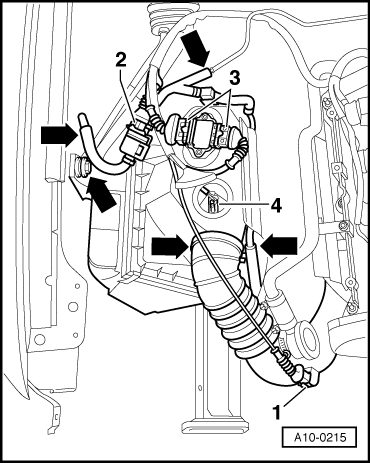

Note: Avoid excessive bending of the decoupling element at front exhaust pipe (max. 10o). Vehicles with 4-cylinder turbo engine:

|

|

|

|

|

|

|

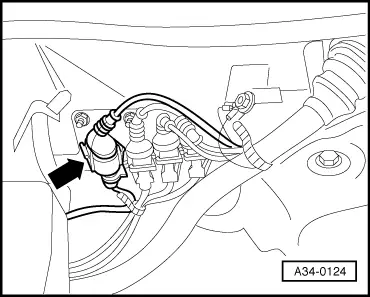

Note: Avoid excessive bending of the decoupling element at front exhaust pipe (max. 10o). Vehicles with 6-cylinder engine:

|

|

|

|

All models:

|

|

|

Vehicles with 4-cylinder engine: |

|

|

|

|

|

|

|

|

|

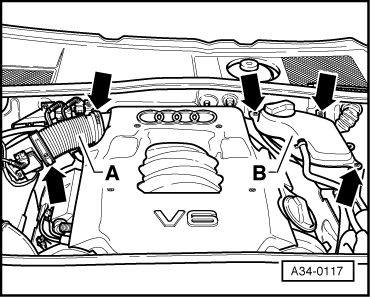

Vehicles with 6-cylinder engine:

=> 6-cylinder Engine (2-valve), Mechanics; Repair Group 26; Removing and installing exhaust system |

|

|

All models: |

|

|

Note: Take care not to damage protective coating on drive shafts.

|

|

|

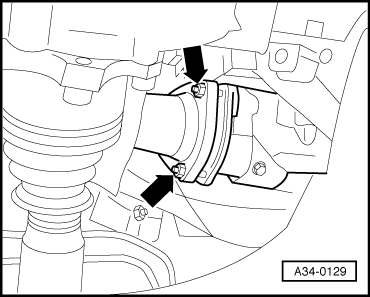

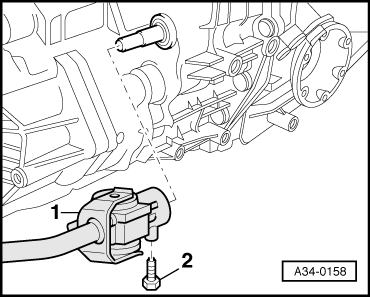

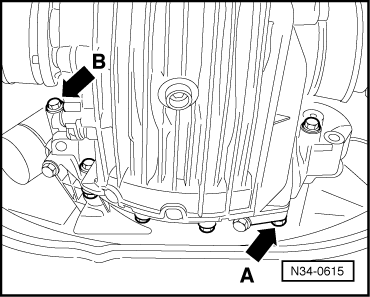

=> Electrical system; Repair Group 27; Removing and installing starter Note: Starter cables do not need to be disconnected. Vehicles with standard-travel shift mechanism: |

|

|

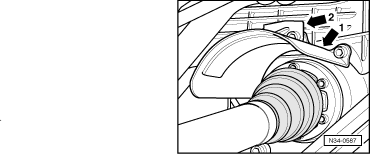

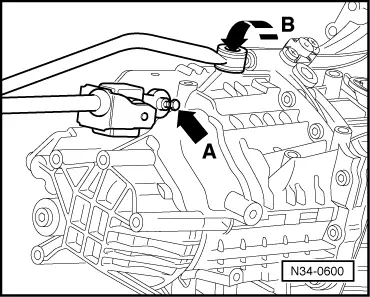

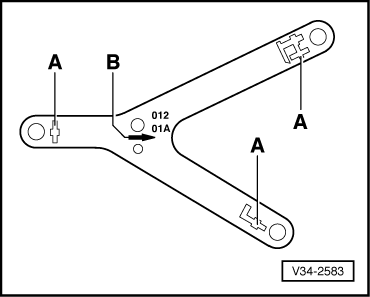

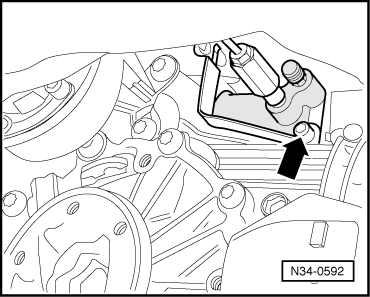

Vehicles with short-travel shift mechanism: |

|

|

Note: Shown in illustration on manual gearbox 012. All models: |

|

|

|

|

|

|

|

|

|

|

|

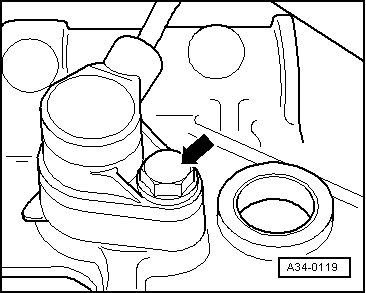

Notes:

|

|

|

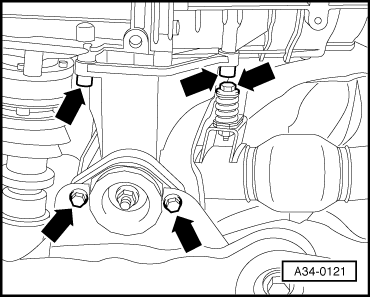

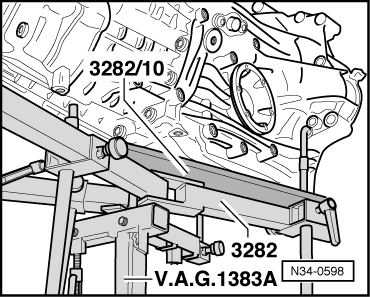

Note: If gearbox support 3282 is not available, gearbox can be removed and installed using gearbox lifter V.A.G 1383 A and universal support V.A.G 1359/2.

|

|

|

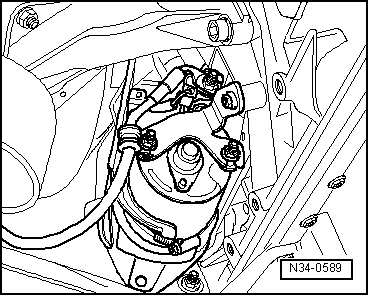

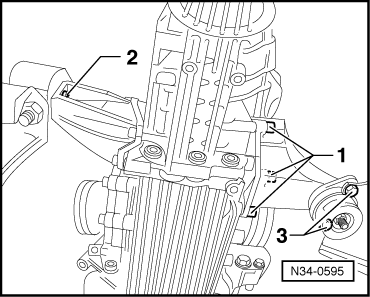

Vehicles with 4-cylinder engine: |

|

|

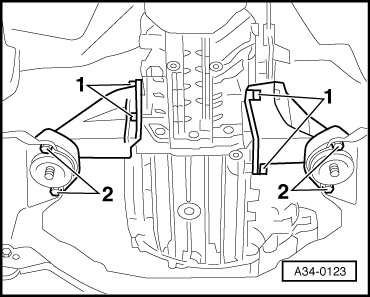

Vehicles with 6-cylinder engine: |

|

|

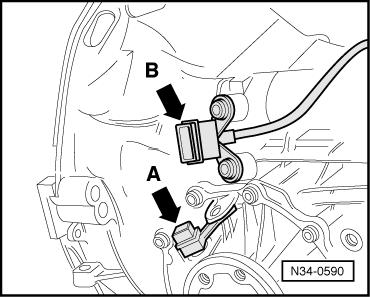

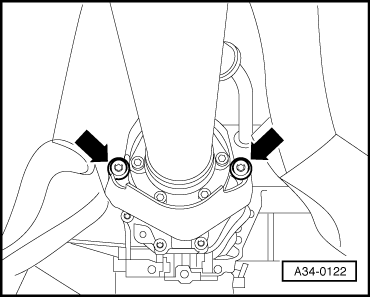

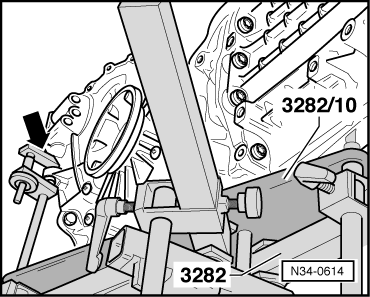

All models: |

|

|

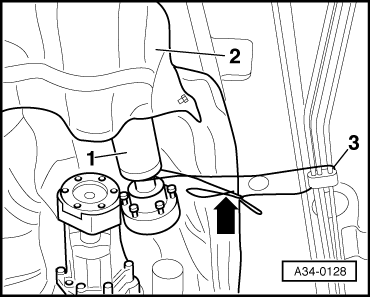

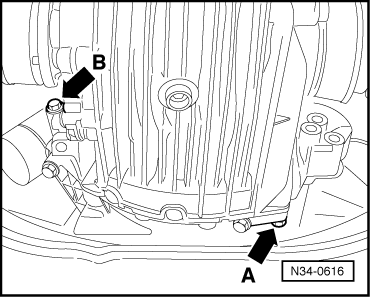

Note: When lowering gearbox ensure hydraulic pipe/hose to slave cylinder is not damaged. |

|

|

Note: Do not depress clutch pedal after removing slave cylinder.

Note: When lowering gearbox ensure there is sufficient clearance to drive shafts. |