A4 Mk1

|

|

|

Notes:

|

|

|

|

|

|

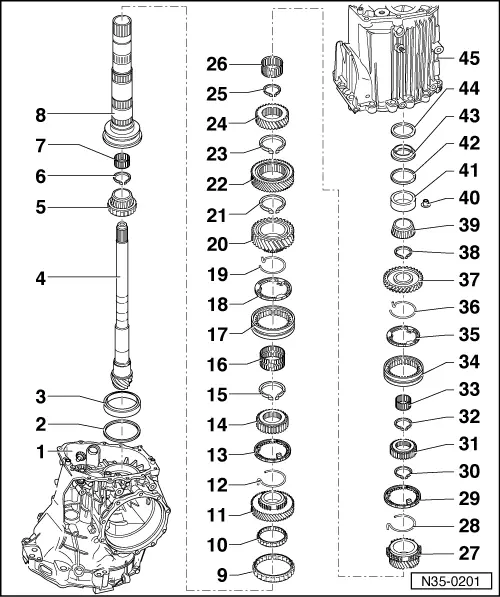

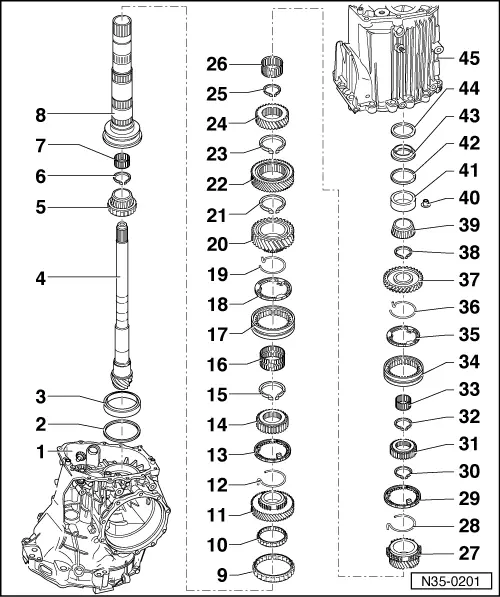

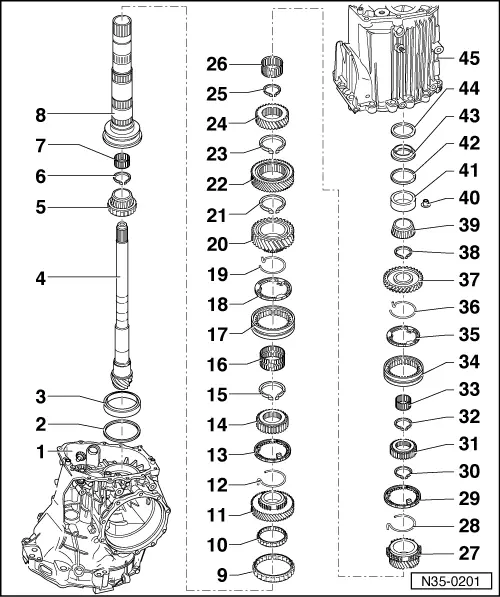

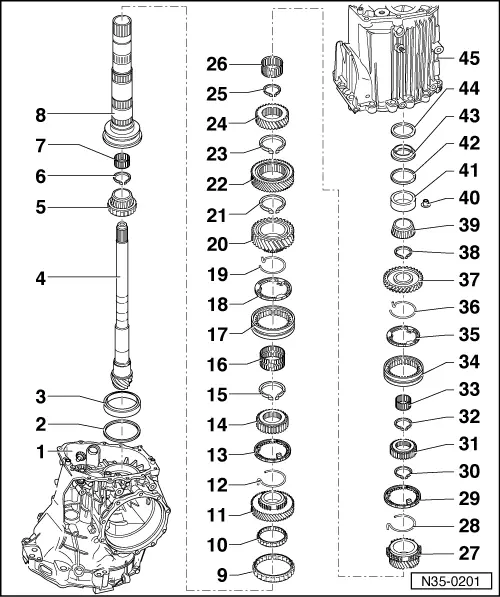

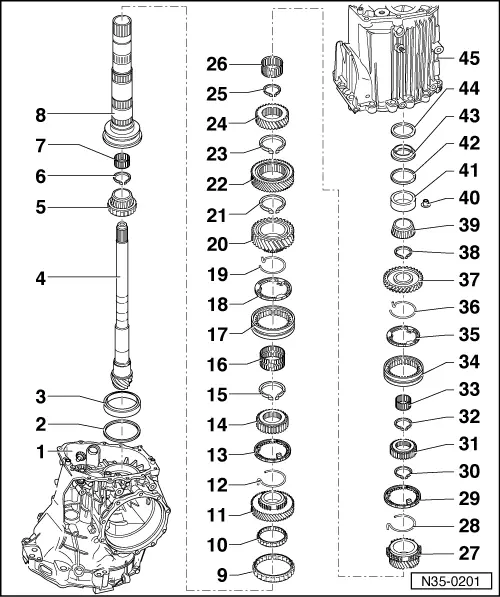

=> Parts List |

|

|

=> Parts List

|

|

|

|

|

=> Parts List |

|

|

=> Parts List |

|

|

|

|

=> Parts List => Parts List

|

|

|

|

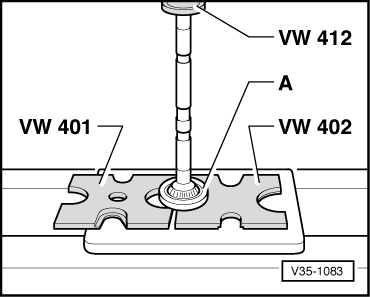

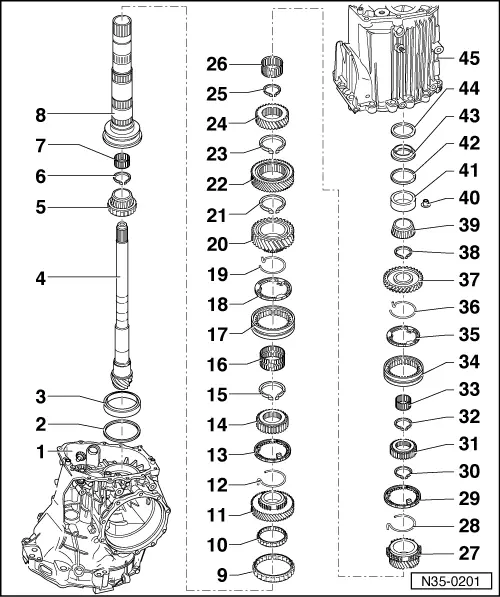

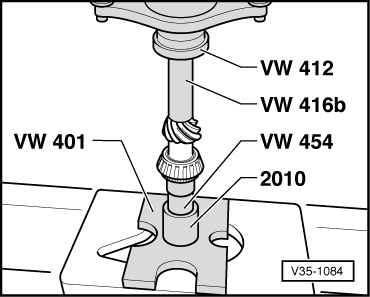

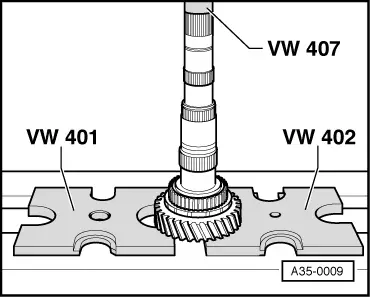

→ Fig.1 Pulling out outer race for double taper roller bearing

When tightening the bolt the outer race will be pulled out of the housing. |

|

|

|

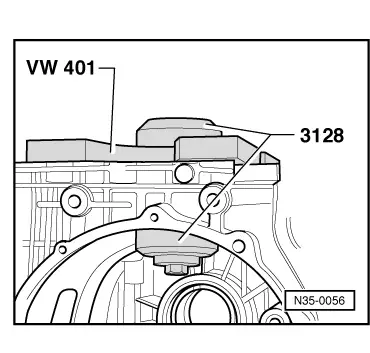

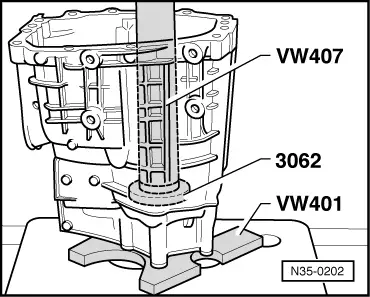

→ Fig.3 Pressing in outer race for double taper roller bearing The smaller diameter of thrust pad VW 3062 faces outer race. |

|

|

|

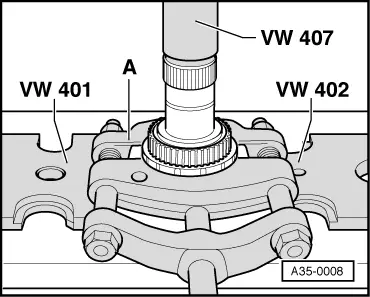

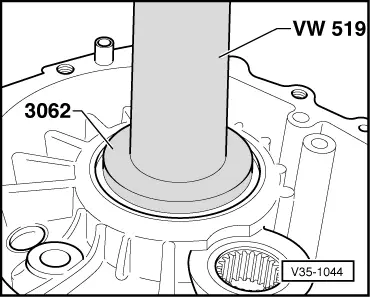

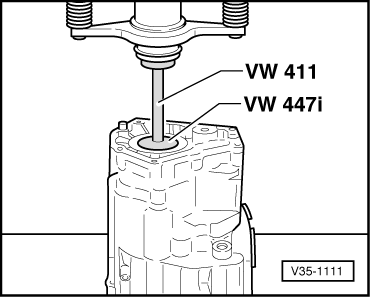

→ Fig.4 Pressing on inner race for double taper roller bearing |

|

|

|

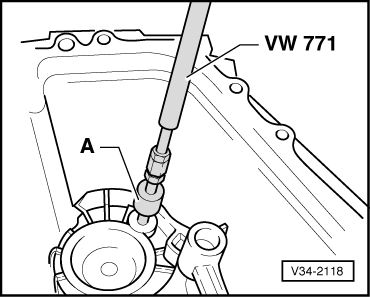

→ Fig.6 Pulling out securing bush for small taper roller bearing outer race

|

|

|

|

→ Fig.7 Pressing out outer race for taper roller bearing

|

|

|

|

→ Fig.8 Pressing in outer race for taper roller bearing |

|

|

|

→ Fig.9 Pressing off inner race for taper roller bearing

|

|

|

|

→ Fig.10 Pressing on inner race for taper roller bearing

|

|

|

|

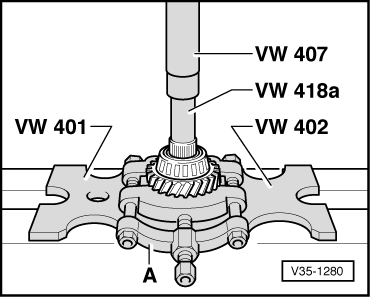

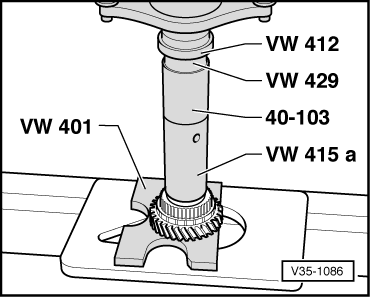

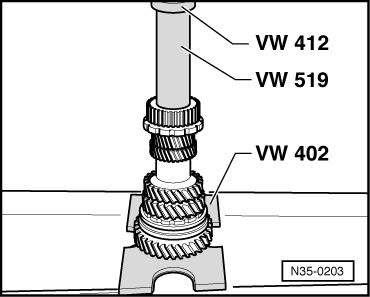

→ Fig.12 Pressing off 4th gear wheel

|

|

|

|

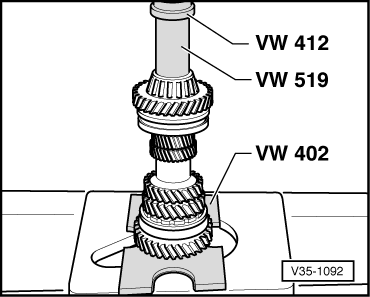

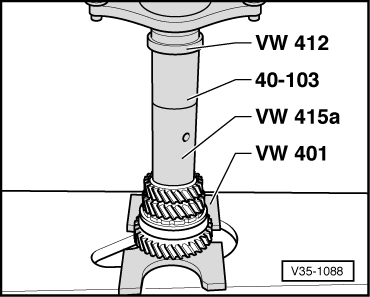

→ Fig.13 Pressing off 3rd gear wheel

|

|

|

|

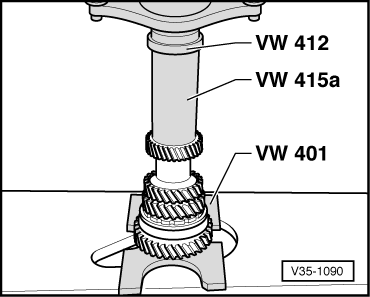

→ Fig.14 Pressing off synchro hub for 1st and 2nd gear

|

|

||||||||||||||||||||

|

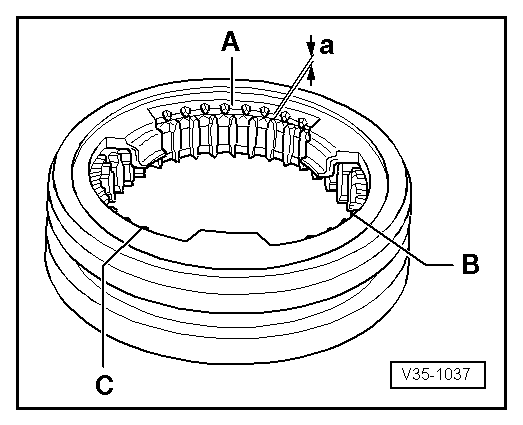

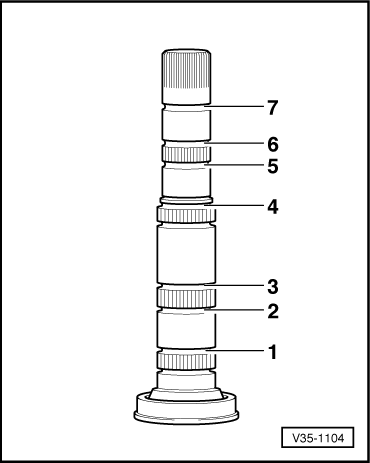

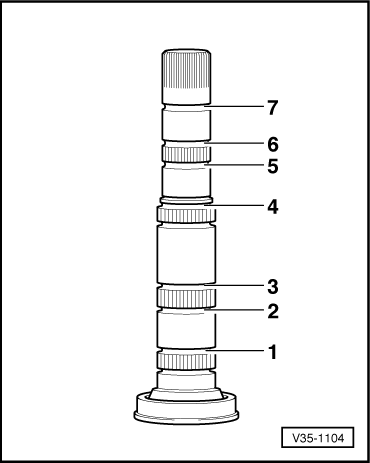

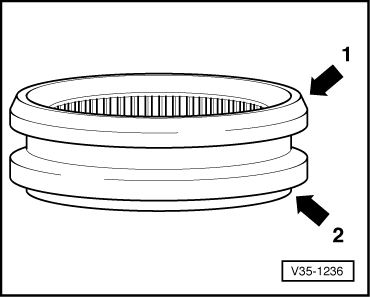

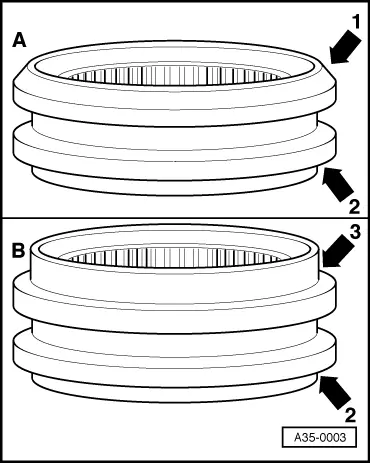

→ Fig.15 Installation position of circlips

| ||||||||||||||||||||

|

||||||||||||||||||||

=> Parts List | ||||||||||||||||||||

|

|

|

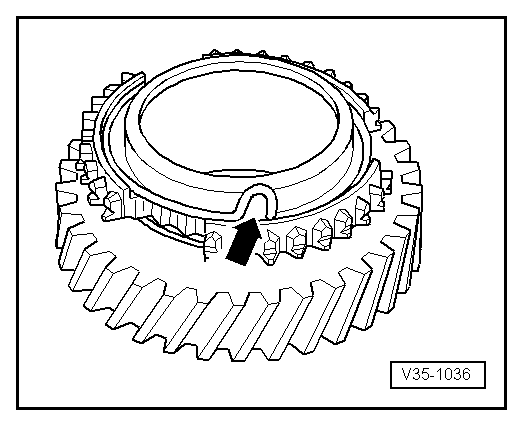

→ Fig.16 Inserting spring in sliding gear The bent end of the spring (arrow) must be hooked in the hole in the sliding gear. |

|

|

|

→ Fig.18 Pressing on synchro-hub for 1st and 2nd gear

|

|

|

|

→ Fig.19 Installation position of locking collar for 1st and 2nd gear

|

|

|

|

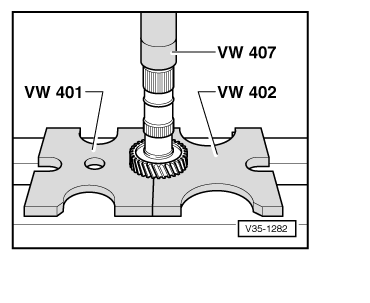

→ Fig.20 Pressing on 3rd gear wheel

|

|

|

|

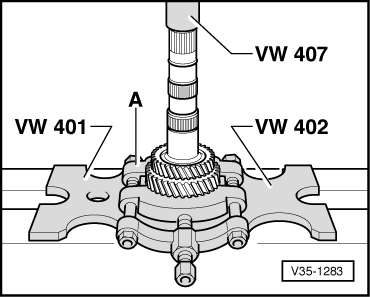

→ Fig.21 Pressing on 4th gear wheel

|

|

|

|

→ Fig.22 Pressing on 5th gear and reverse gear synchro hub

|

|

|

|

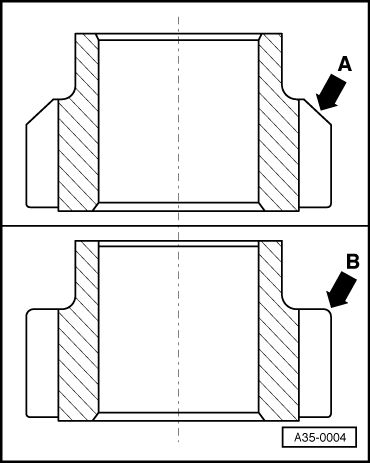

→ Fig.23 Installation position of locking collar for 5th and reverse gear Only locking collars with chamfered edges -A- as well as with large shoulders -B- are fitted.

|