A4 Mk1

|

Servicing end cover

Servicing end cover

|

|

|

|

Note: General repair instructions . |

|

|

|

|

|

|

|

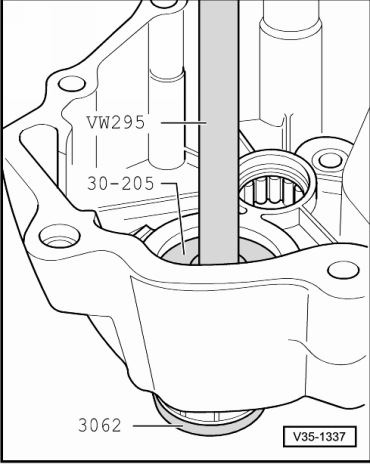

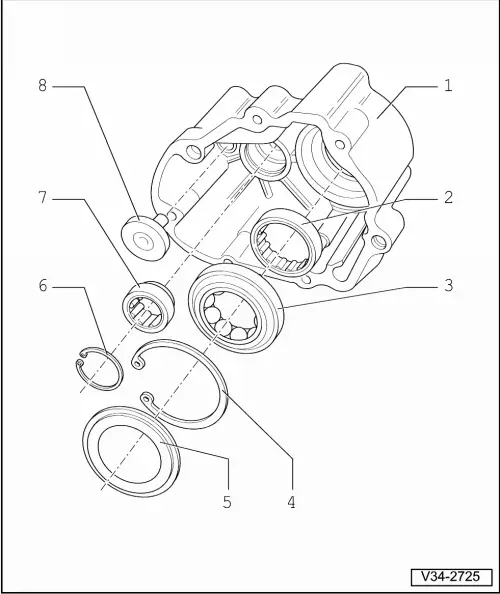

→ Fig.1 Pressing cylinder roller bearing for input shaft out of end cover |

|

|

|

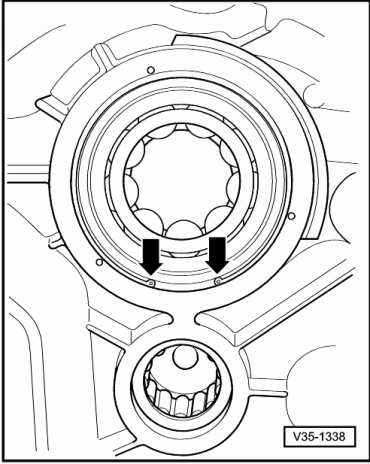

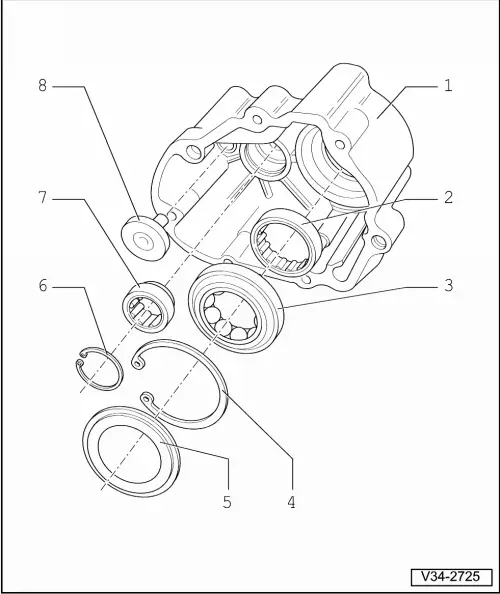

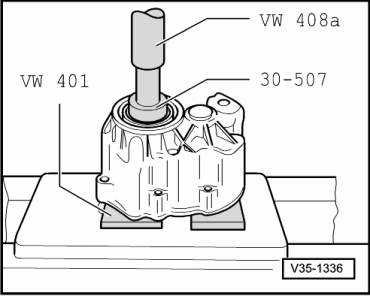

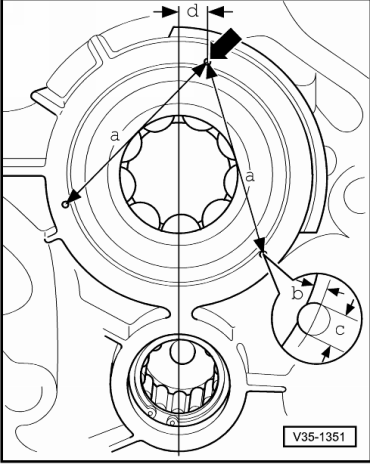

→ Fig.5 Peening baffle plate in position when renewing four-point bearing for input shaft

|

|

|

|

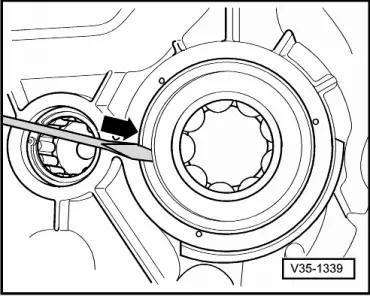

→ Fig.6 Peening baffle plate in position when renewing end cover

|

|

|

|

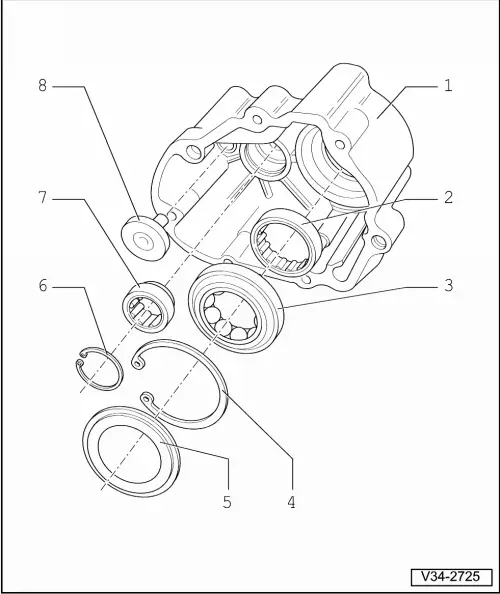

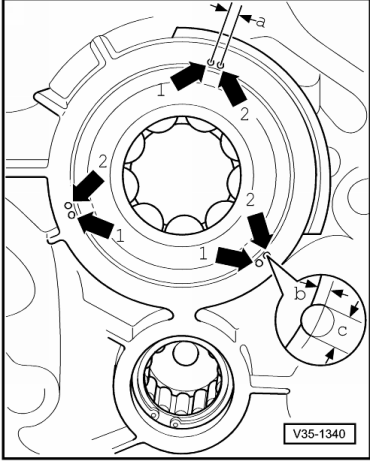

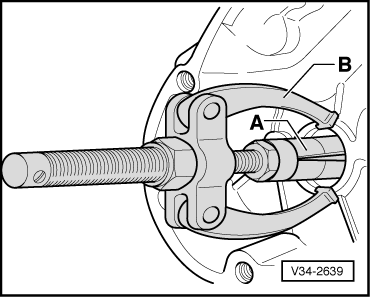

→ Fig.7 Pulling roller sleeve for drive pinion out of end cover

|

|

|

|

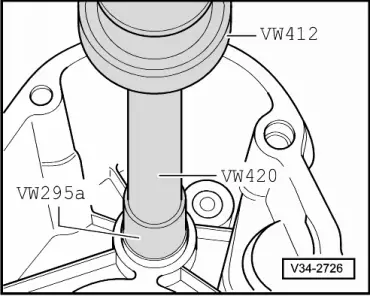

→ Fig.8 Driving roller sleeve for drive pinion into end cover

|

|

|

|

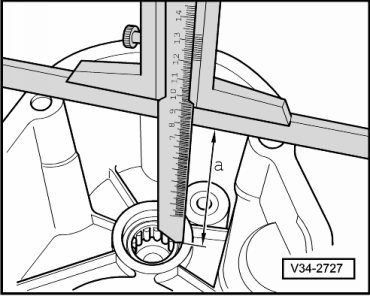

→ Fig.9 Installation position of roller sleeve for drive pinion

|