|

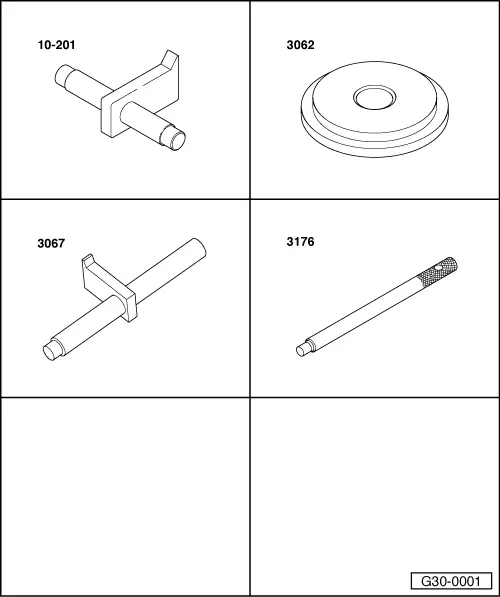

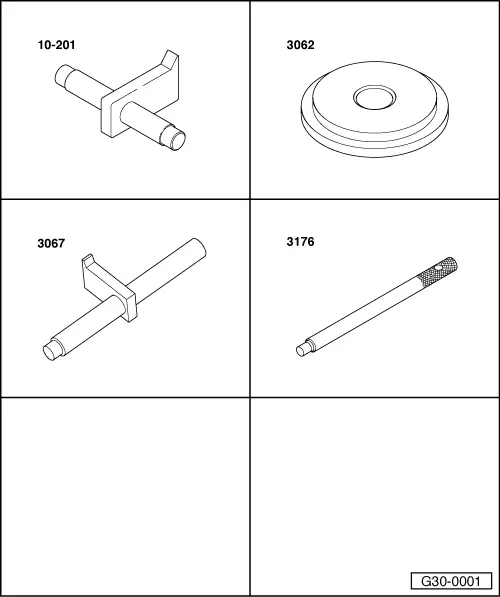

Special tools and workshop equipment required

-

◆ Counterhold 10-201

-

◆ Thrust pad 3062

-

◆ Counterhold 3067 (for vehicles with V6 TDI engine)

-

◆ Centring mandrel 3176

-

◆ Grease G 000 100

Notes:

-

◆ Heed general repair instructions .

-

◆ Before replacing clutch plate and pressure plate, refer to

=> Fault-finding No. 9 - Complaints about clutch and clutch mechanism

-

◆ Vehicles with V6 2.7l bi-turbo engine (S4 and RS4) are fitted with an SAC pressure plate (SAC = self-adjusting clutch) which requires resetting of an adjuster ring if only the clutch plate is replaced.

-

◆ So as not to damage SAC pressure plate on removal and installation, pay attention to assembly specifications for SAC pressure plate

=> Page 30-56.

-

◆ Checking SAC pressure plate for torsion => Page 30-55, Fig.2

-

◆ Replace clutch plates and pressure plates where riveted joint is damaged or loose.

-

◆ Assign clutch plate and pressure plate by way of engine code.

=> Parts List

-

◆ Clean input shaft splines and - in the case of used clutch plates - hub splines, remove corrosion and apply extremely thin layer of grease G 000 100 to splines. Then move clutch plate back and forth on input shaft until hub moves freely on shaft. Excess grease must be removed.

-

◆ Pressure plates have an anti-corrosion coating and are greased. Only the contact surface may be cleaned, as otherwise the clutch service life will be considerably shortened.

-

◆ To reduce the odour nuisance of a scorched clutch, thoroughly clean bell housing, flywheel and parts of engine facing gearbox.

|