Adjust Crown Wheel for Enhanced Performance

|

Adjusting crown wheel

Adjusting crown wheel

|

|

|

|

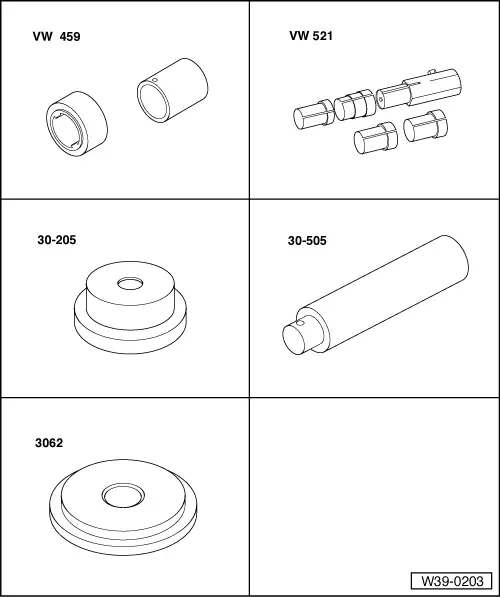

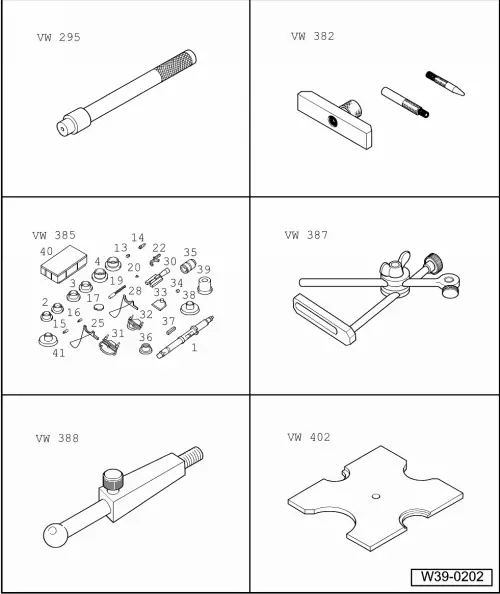

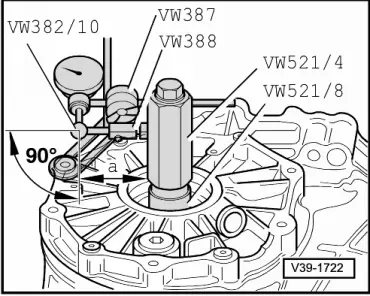

(differential adjustment) Operations following which crown wheel has to be adjusted => Table, Page 39-57 Special tools, workshop equipment, testers, measuring instruments and other items required

|

|

|

Note: A 1.20 mm thick shim "S2" is provisionally inserted as standard measure. This is referred to in the following as "S2*". "S2*" is replaced with final "S2" after determining backlash. |

|

|

|

|

|

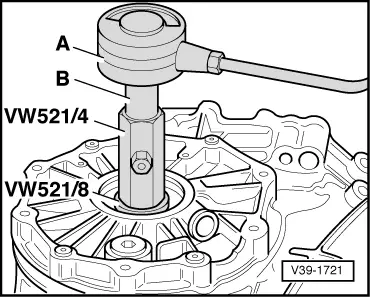

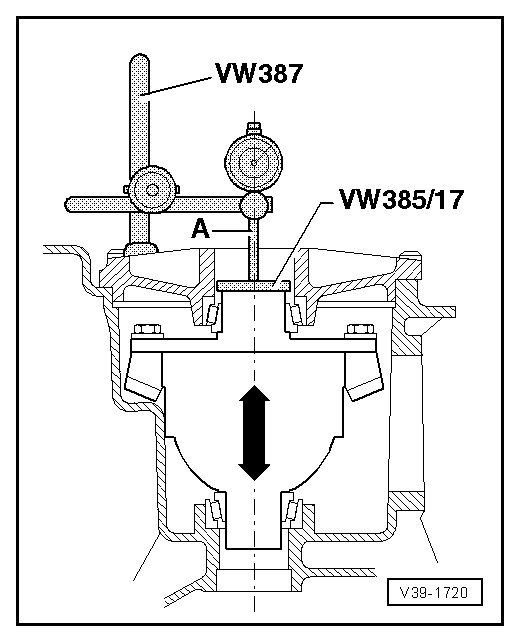

Note: Tip of dial gauge must be located at centre of differential.

Notes: |

|

|||||||||||||||||||||||||||||||||||||||||

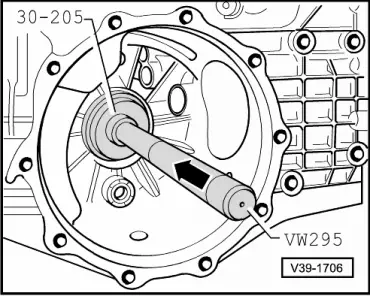

Determining thickness of shim "S1*" Notes:

Measuring friction torque (check) Notes:

| |||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

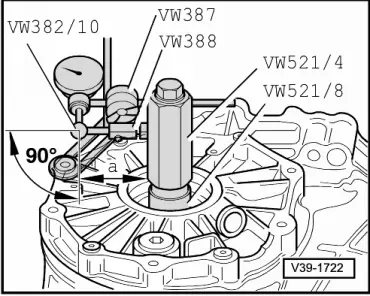

Note: If the individual values determined in this measurement differ by more than 0.06 mm, there is a problem either with the installation of the crown wheel or with the actual pinion set. Check assembly operations and replace pinion set if necessary. Determining average backlash

Determining thickness of shim "S2"

=> Parts List Shims available for "S2"

1) The tolerances of the shims permit determination of any thickness; fit 2 shims if necessary Determining thickness of shim "S1"

=> Parts List Shims available for "S1"

1) The tolerances of the shims permit determination of any thickness; fit 2 shims if necessary | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

→ Check measurement

Notes:

|