A4 Mk1

|

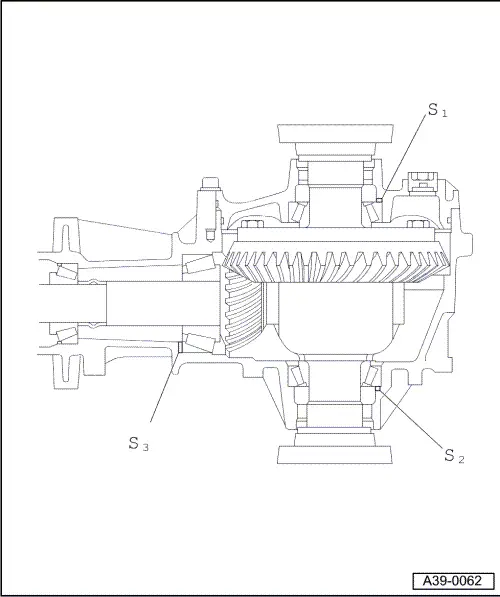

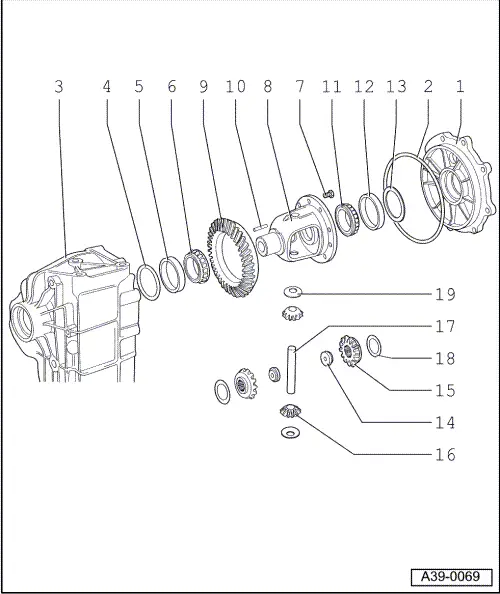

Dismantling and assembling differential

Dismantling and assembling differential

|

|

|

|

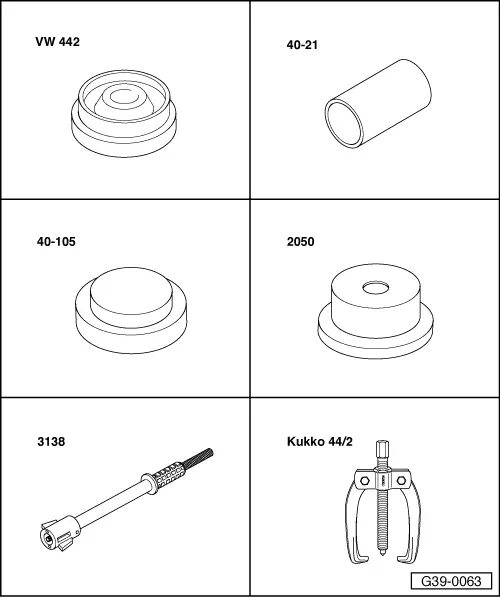

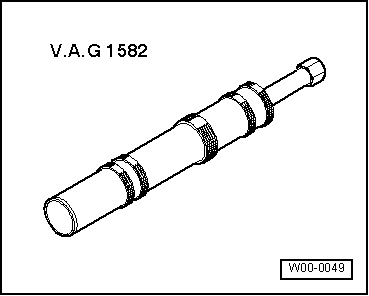

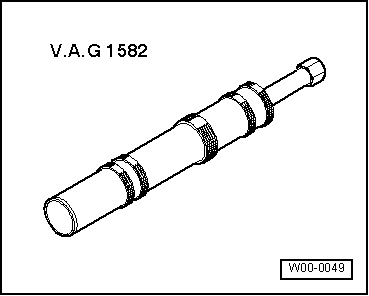

Special tools, testers and other items required

|

|

|

|

|

|

|

|

|

|

|

|

|

Notes:

|

|

|

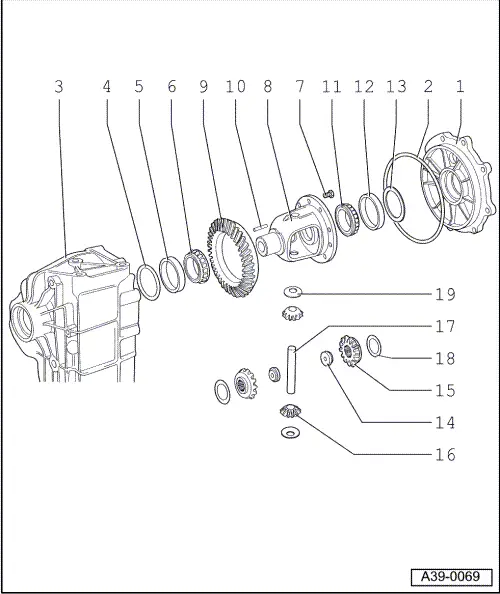

=> Parts List

|

|

|

=> Parts List |

|

|

|

|

|

|

|

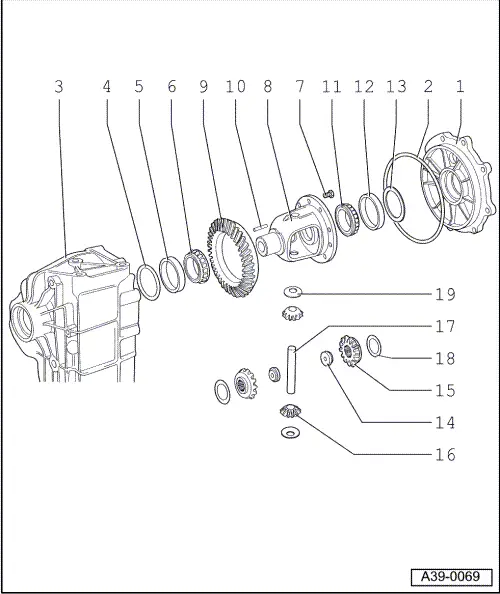

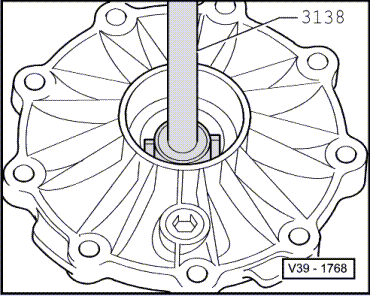

→ Fig.1 Driving outer race for taper roller bearing, small out of housing

|

|

|

|

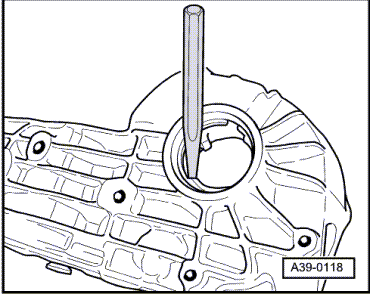

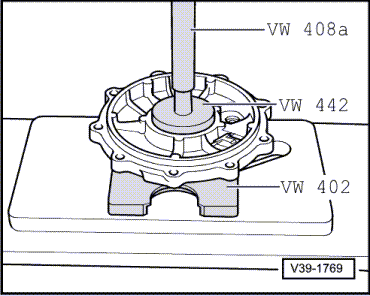

→ Fig.2 Pressing home outer race for taper roller bearing, small in housing

|

|

|

|

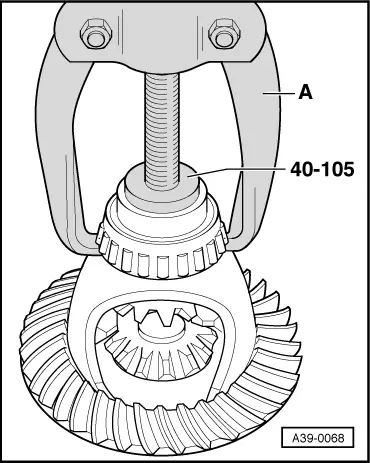

→ Fig.3 Pulling off inner race for taper roller bearing, small

|

|

|

|

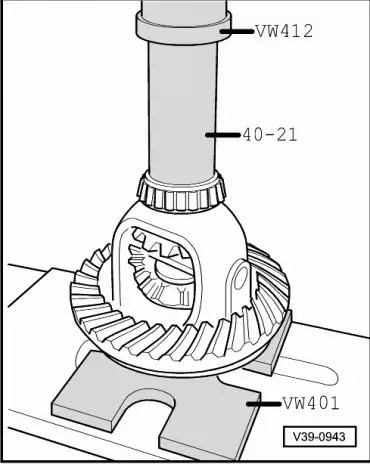

→ Fig.4 Pressing on inner race for taper roller bearing, small Attention:

Wear protective gloves.

|

|

|

|

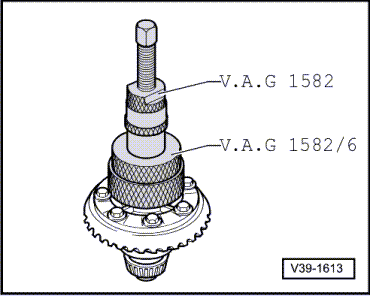

→ Fig.5 Pulling off inner race for taper roller bearing, large

|

|

|

|

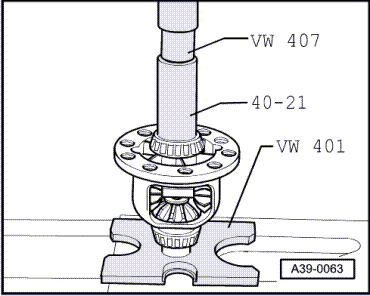

→ Fig.6 Pressing on inner race for taper roller bearing, large Attention:

Wear protective gloves.

|

|

|

|

→ Fig.7 Driving outer race for taper roller bearing, large out of cover

|

|

|

|

→ Fig.8 Pressing outer race for taper roller bearing, large into cover |

|

|

|

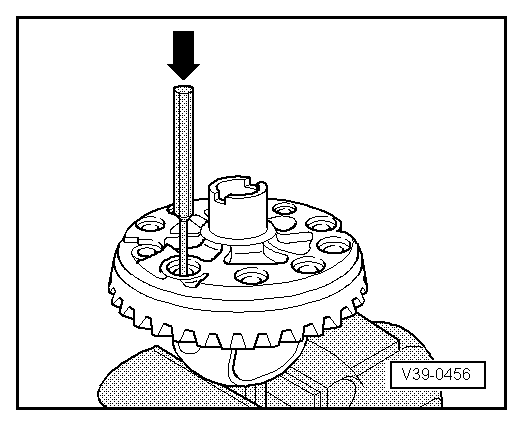

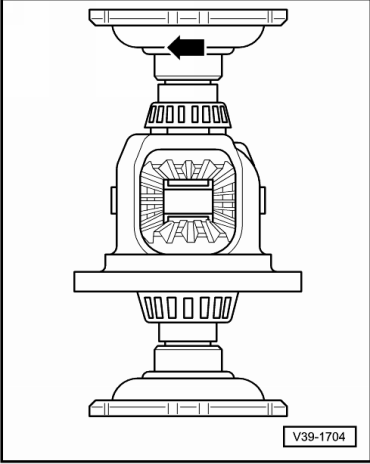

→ Fig.9 Driving crown wheel off housing |

|

|

|

→ Fig.10 Fitting crown wheel Attention:

Wear protective gloves.

|

|

|

|

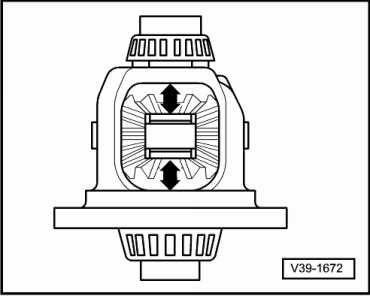

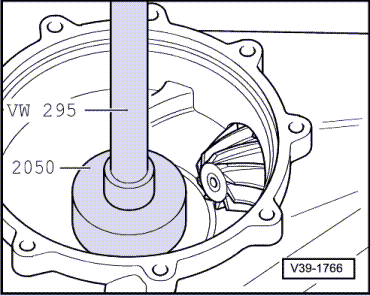

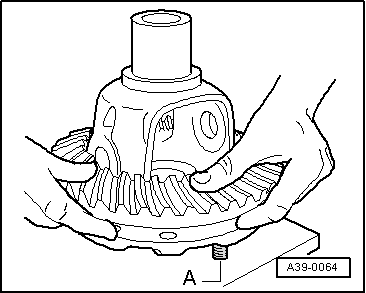

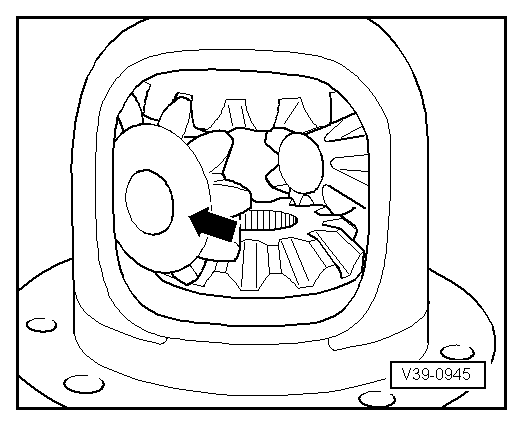

→ Fig.11 Installing bevel gears

|

|

|

|

Note: → Correct setting has also been made if there is no perceptible clearance, but bevel gears can still just be turned -arrow-. |