A4 Mk1

|

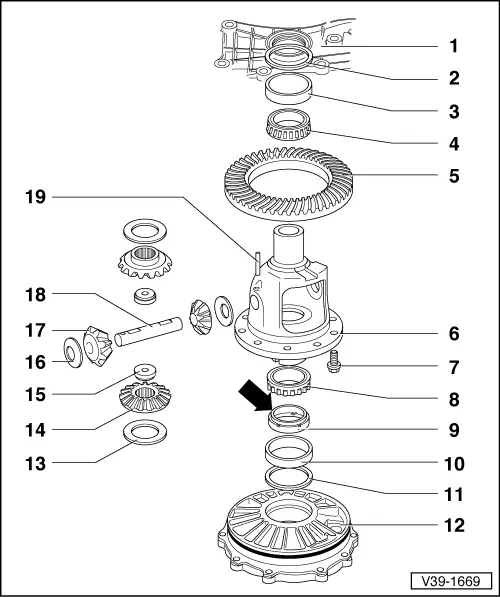

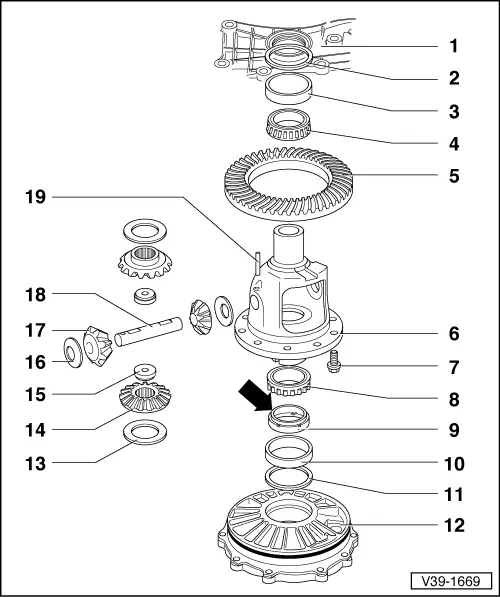

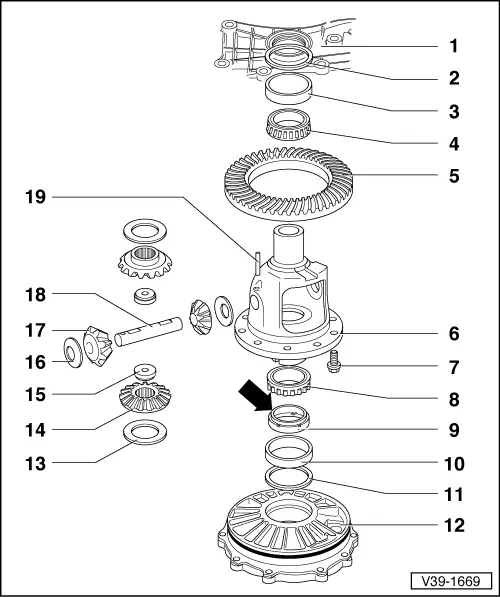

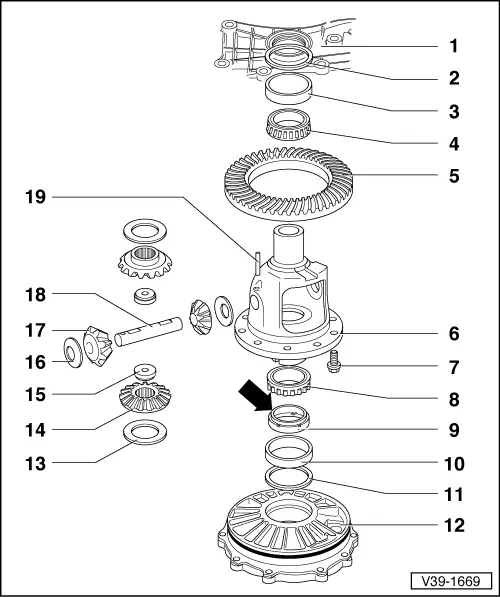

Dismantling and assembling differential (gearbox with no oil pump)

Dismantling and assembling differential (gearbox with no oil pump)

|

|

|

|

|

|

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|

|

|

|

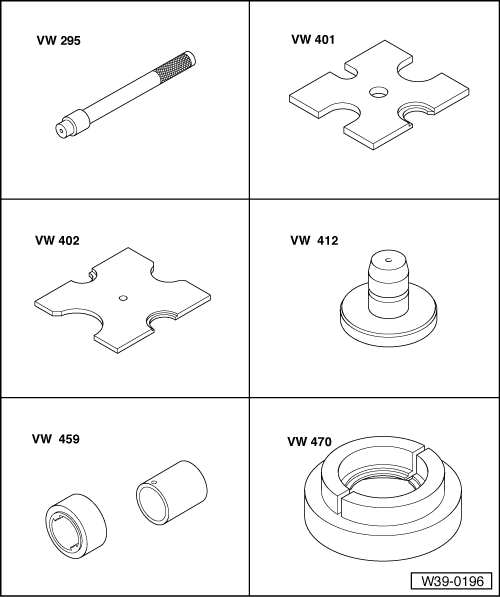

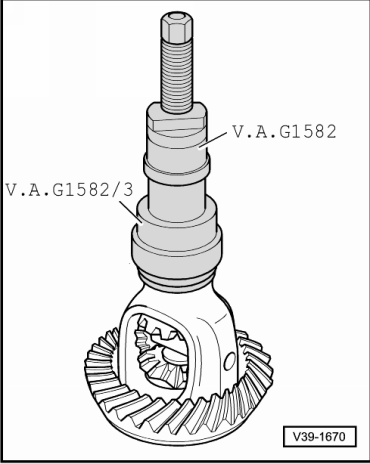

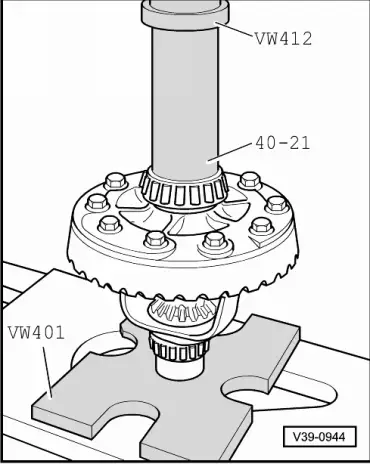

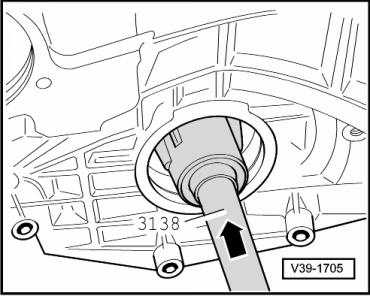

→ Fig.1 Pulling inner race for taper roller bearing, small off housing

|

|

|

|

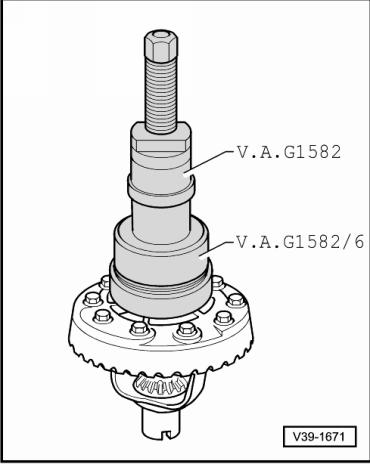

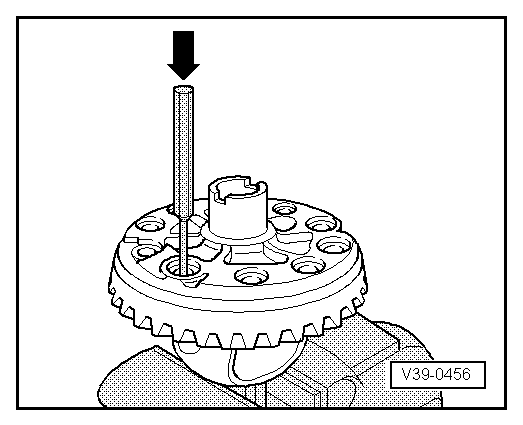

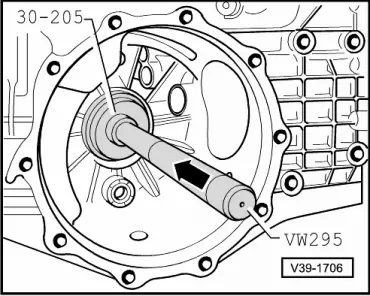

→ Fig.2 Pulling inner race for taper roller bearing, large off housing

|

|

|

|

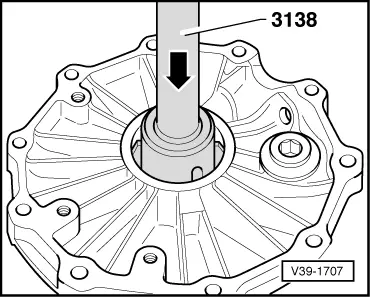

→ Fig.3 Pressing on inner race for taper roller bearing, small

Attention:

Wear protective gloves. |

|

|

|

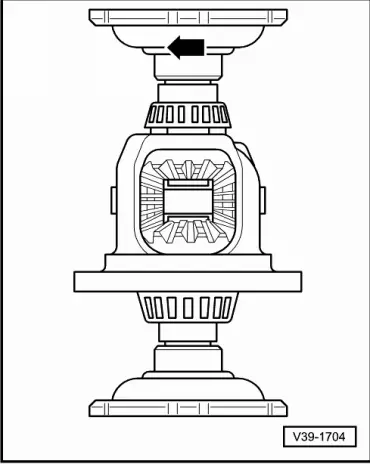

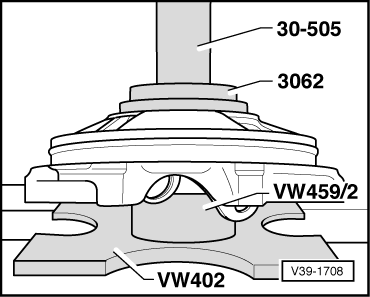

→ Fig.4 Pressing on inner race for taper roller bearing, large

Attention:

Wear protective gloves. |

|

|

|

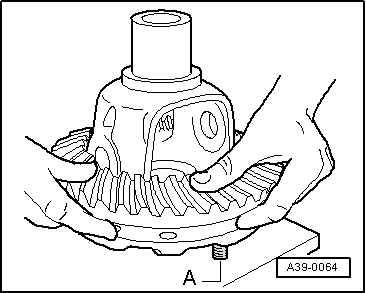

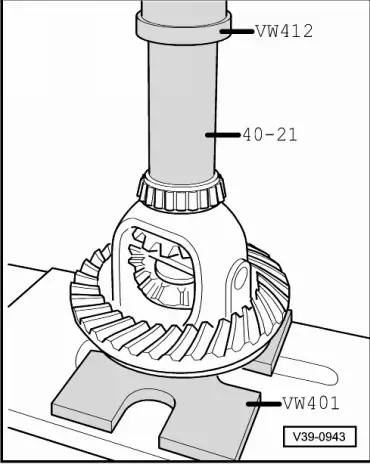

→ Fig.5 Driving crown wheel off housing |

|

|

|

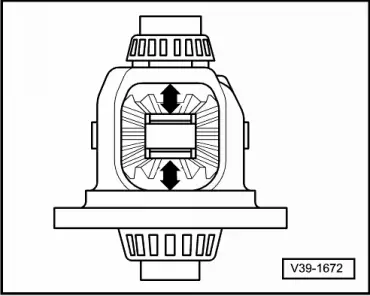

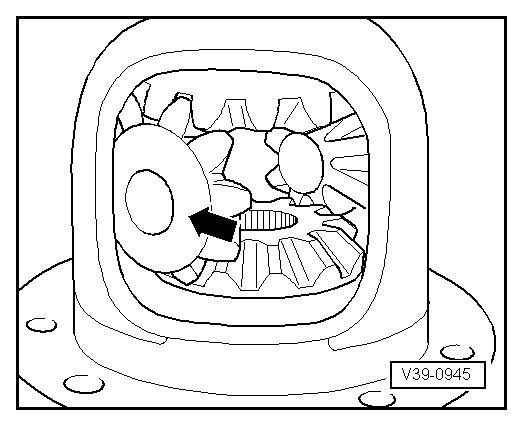

→ Fig.7 Installing bevel gears

|

|

||||||||||

Note: → Correct setting has also been made if there is no perceptible clearance, but bevel gears can still just be turned -arrow-.

=> Parts List Shims available

| ||||||||||

|

|

|

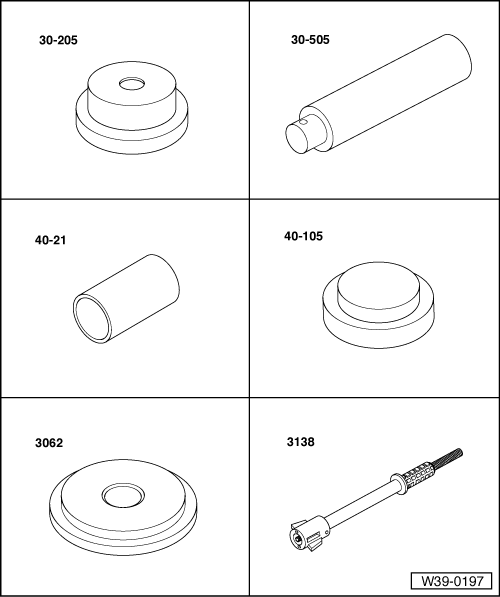

→ Fig.9 Driving outer race for taper roller bearing, small out of gearbox housing |

|

|

|

Fig.10 → Driving outer race for taper roller bearing, small into gearbox housing |

|

|

|

→ Fig.11 Driving outer race for taper roller bearing, large out of cover

|

|

|

|

→ Fig.12 Driving outer race for taper roller bearing, large into cover |