A4 Mk1

|

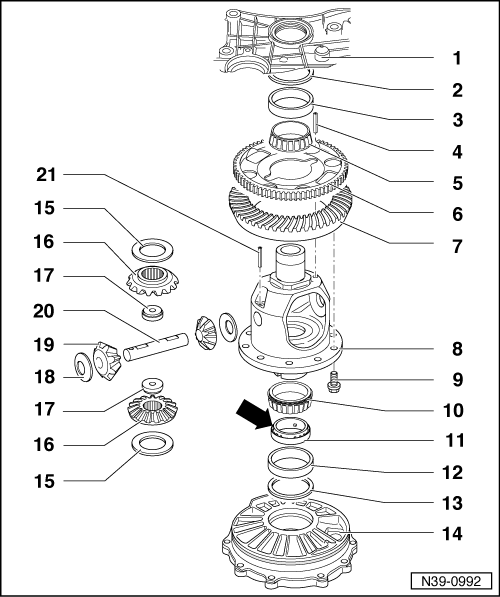

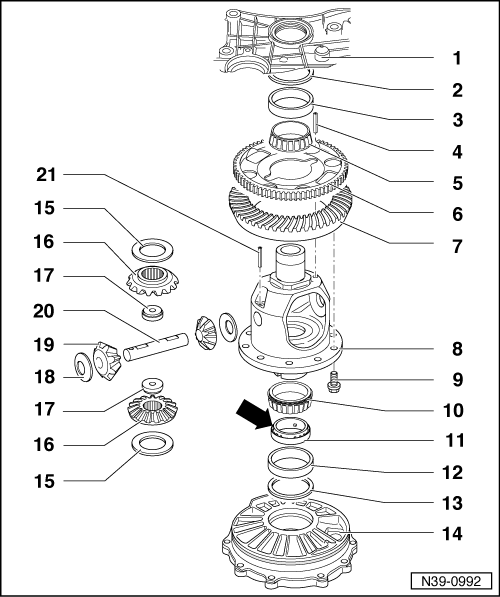

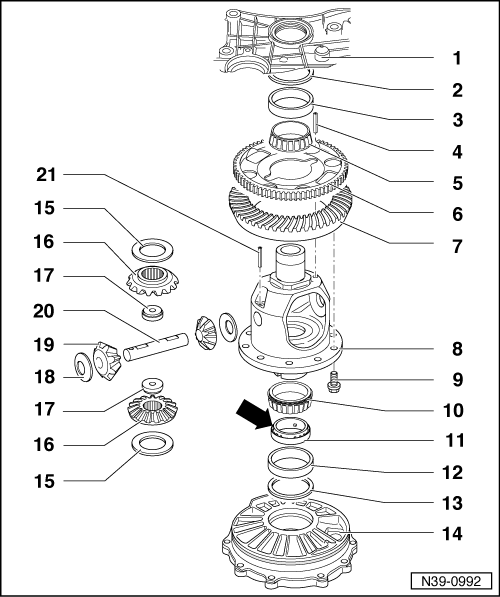

Dismantling and assembling differential (gearbox with oil pump)

Dismantling and assembling differential (gearbox with oil pump)

|

|

|

|

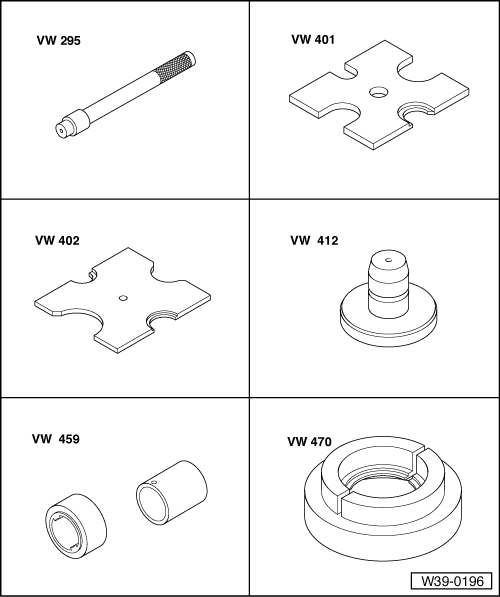

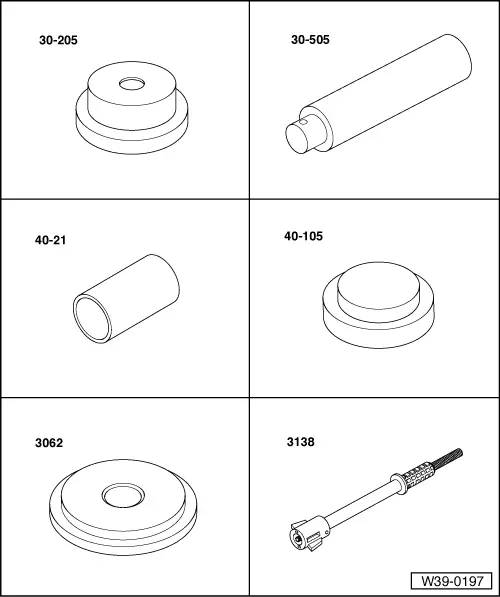

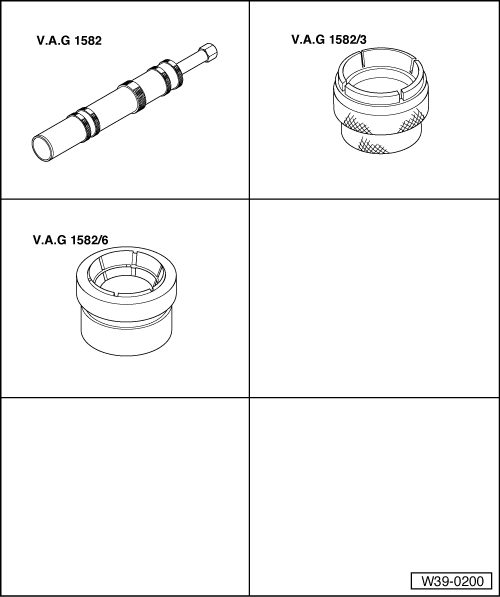

Special tools, workshop equipment, testers, measuring instruments and other items required

|

|

|

|

Special tools, workshop equipment, testers, measuring instruments and other items required

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

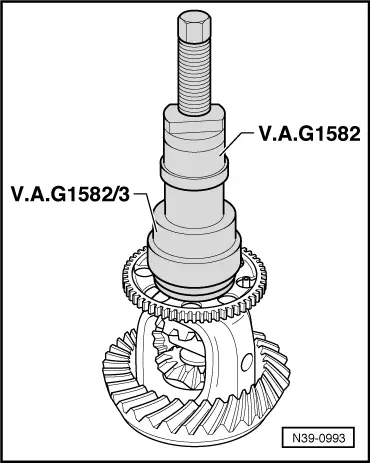

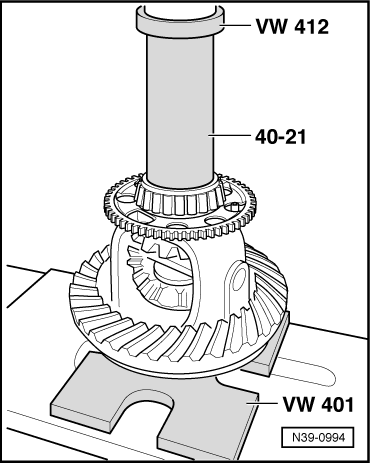

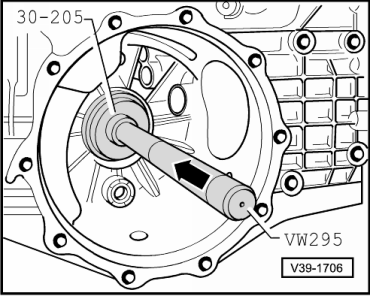

→ Fig.1 Pulling off small taper roller bearing inner race

|

|

|

|

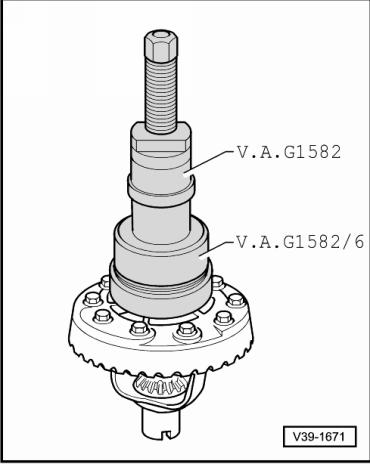

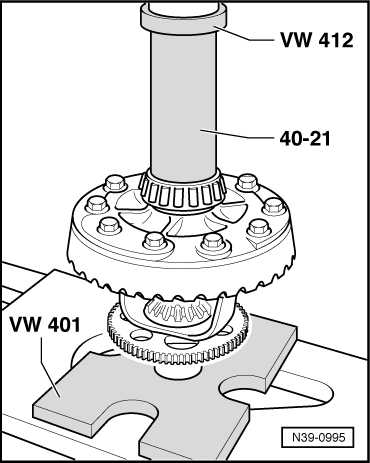

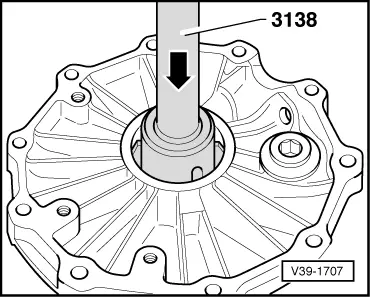

→ Fig.2 Pulling off large taper roller bearing inner race

|

|

|

|

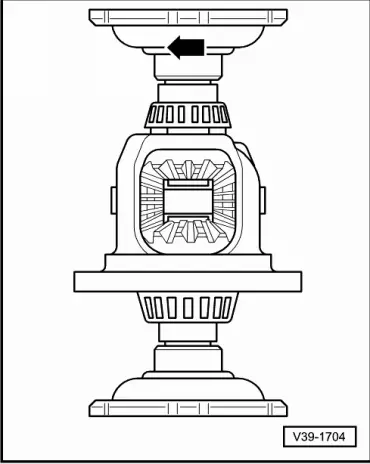

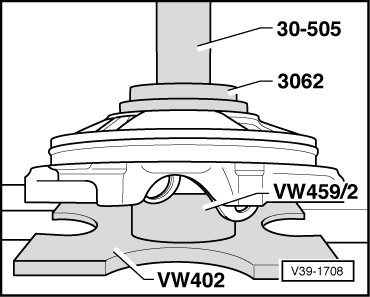

→ Fig.3 Pressing on small taper roller bearing inner race

|

|

|

|

→ Fig.4 Pressing on large taper roller bearing inner race

|

|

|

|

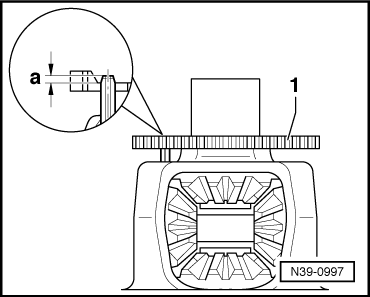

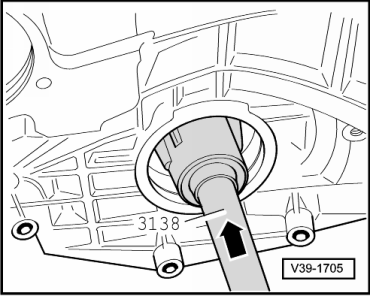

→ Fig.5 Installation position of large drive gear for oil pump

|

|

|

|

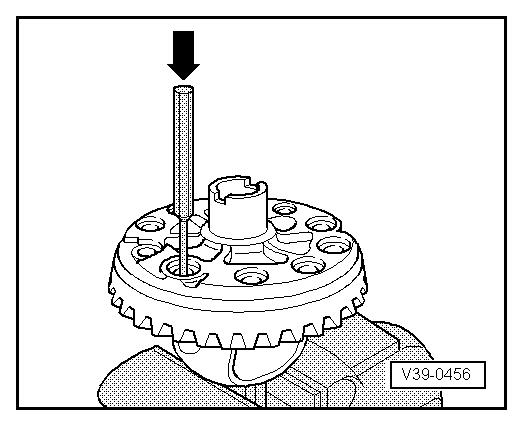

→ Fig.6 Driving in spring pin for large drive gear -1-

|

|

|

|

→ Fig.7 Driving crown wheel off housing |

|

|

|

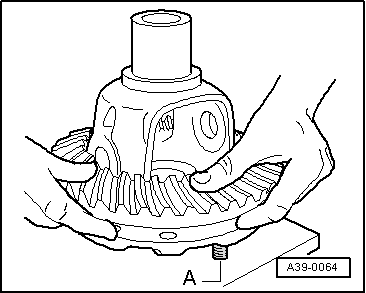

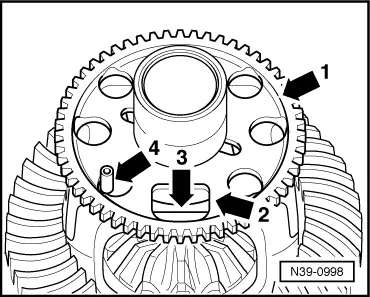

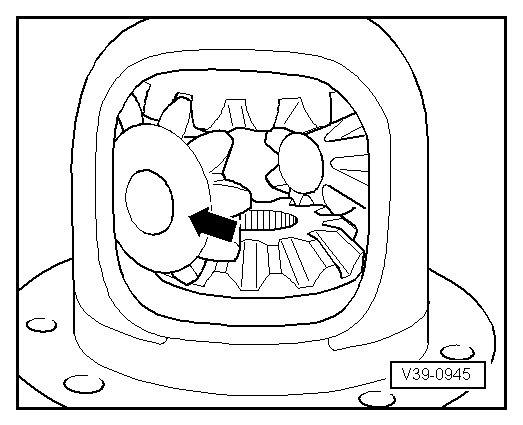

→ Fig.9 Installing bevel gears

|

|

|

|

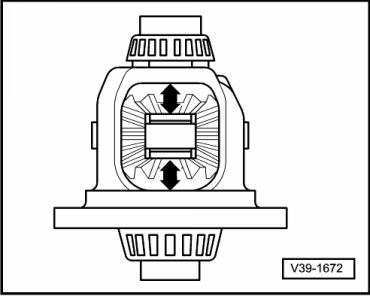

→ Fig.10 Adjusting bevel gears

Note: From now on sun wheels and thrust washers are not to be interchanged.

|

|

|

|

→ Fig.11 Driving small taper roller bearing outer race out of gearbox housing |

|

|

|

→ Fig.12 Driving small taper roller bearing outer race into gearbox housing |

|

|

|

→ Fig.13 Driving large taper roller bearing outer race out of cover

|

|

|

|

→ Fig.14 Driving large taper roller bearing outer race into cover |