|

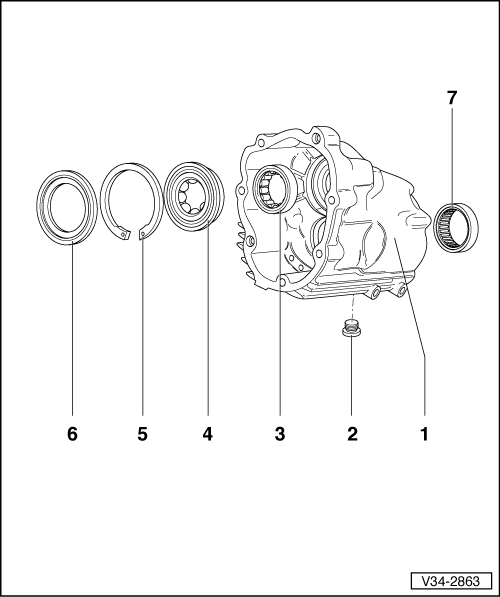

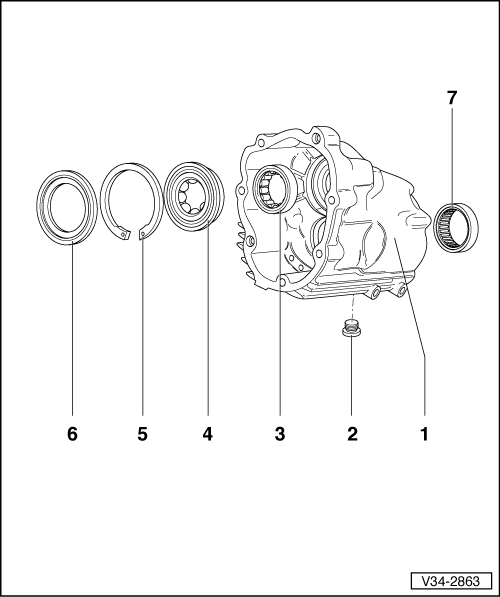

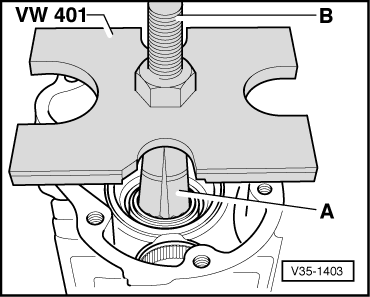

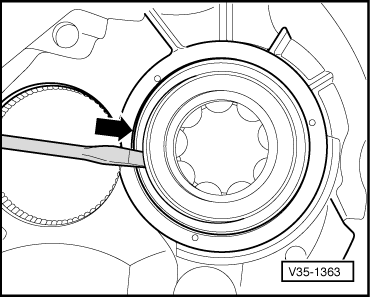

→ Fig.4 Installing ball bearing for input shaft in end cover

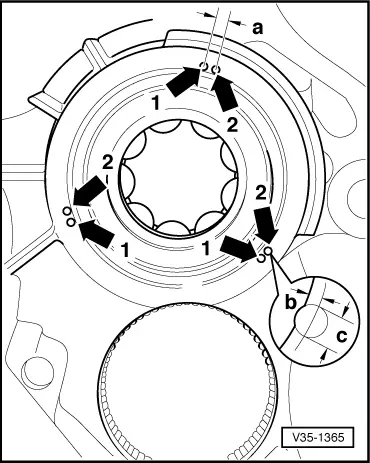

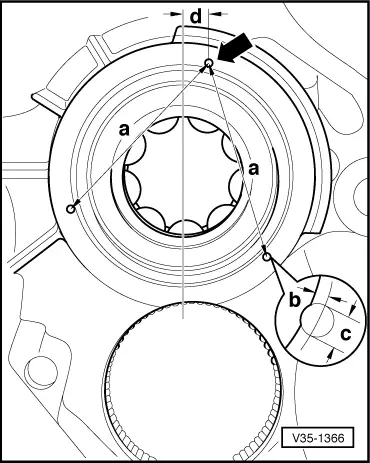

Installation position of circlip:

-

◆ Ends of circlip -arrows- face needle bearing

Note:

Circlip thickness must be re-determined on replacing bearing or end cover.

-

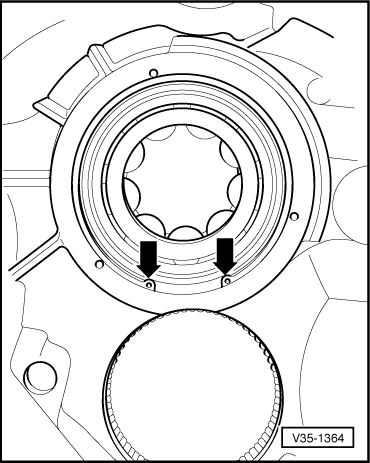

‒ Determining circlip for ball bearing for input shaft:

-

‒ Press home outer race of ball bearing.

-

‒ Determine thickest circlip which can still just be fitted.

-

‒ Axial clearance: max. 0.08 mm

-

‒ Determine circlip from table. Part numbers

=> Parts List

Circlips available:

|

|

|---|

|

Circlip thickness (mm)

|

|

2.55

|

2.65

|

|

2.60

|

2.70

|

|