A4 Mk1 Automatic Gearbox 01V Self-diagnosis: Multi-function switch F125 Check

|

Electrical check

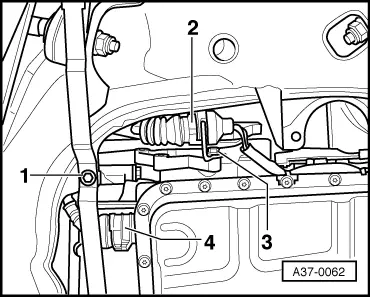

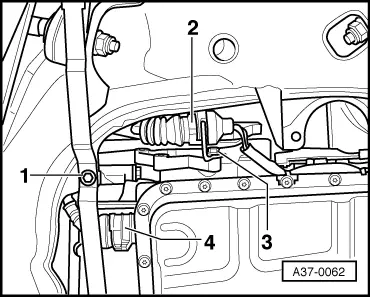

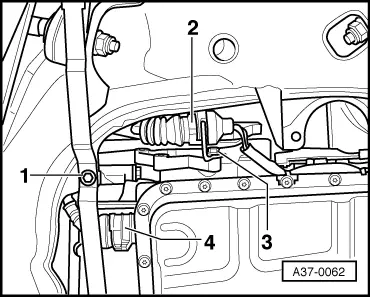

Checking multi-function switch -F125 (driving range sensor)

Notes:

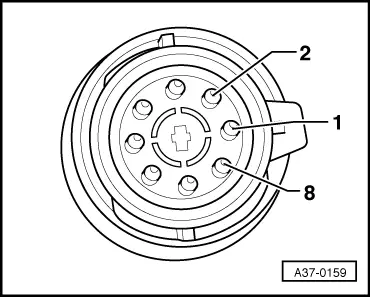

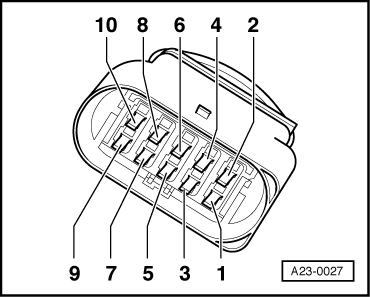

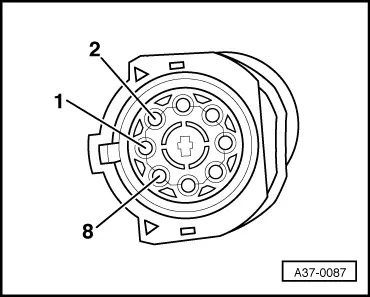

Use is made of two different multi-function switches: 1. Multi-function switch with 8-pin connector=>Checking, Page 01-315 onwards 2. Multi-function switch with 10-pin connector=>Checking, Page 01-326 onwards Checking for multi-function switch with 8-pin connector |

|

|

|

1. Checking operation

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Checking for gearbox with 8-pin connector at multi-function switch -F125

1) Switch V.A.G 1526 to maximum ω range Checking for gearbox with 8-pin connector at multi-function switch -F125

1) Switch V.A.G 1526 to maximum ω range Checking for gearbox with 8-pin connector at multi-function switch -F125

1) Switch V.A.G 1526 to maximum ω range Notes:

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

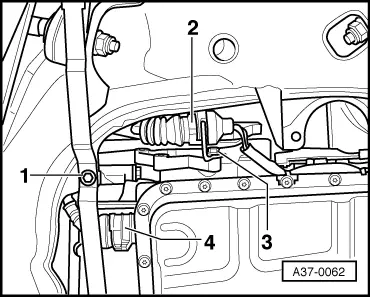

2. Checking power supply of 8-pin multi-function switch

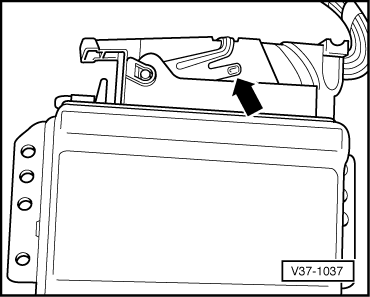

Checking is performed at connector with spring clip (sockets) to gearbox control unit. |

|

|||||||||

Notes: If functional check and power supply of multi-function switch are OK, check wiring from automatic gearbox control unit -J217 to multi-function switch -F125 => Page 01-321 | |||||||||

|

|

|

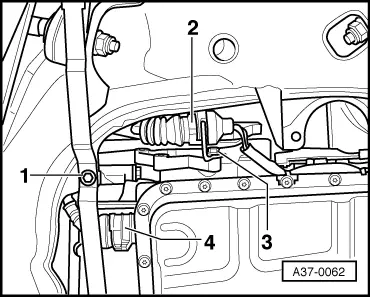

3. Checking wiring from automatic gearbox control unit -J217 to 8-pin multi-function switch -F125

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Checking for gearbox with 8-pin connector at multi-function switch -F125

Checking for gearbox with 8-pin connector at multi-function switch -F125

1) Switch V.A.G 1526 to maximum ω range 2) Fuse for multi-function switch -F125 power supply | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

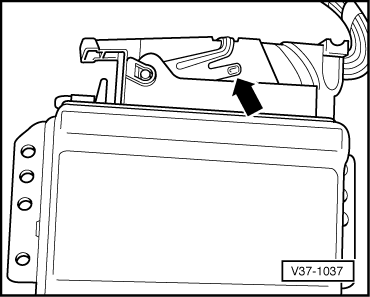

4. Checking wiring from automatic gearbox control unit -J217 to 8-pin connector at multi-function switch

|

|

|

|

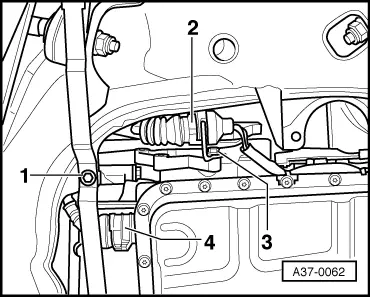

1. Checking operation

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Checking for gearbox with 10-pin connector at multi-function switch -F125

1) Switch V.A.G 1526 to maximum ω range

1) Switch V.A.G 1526 to maximum ω range

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

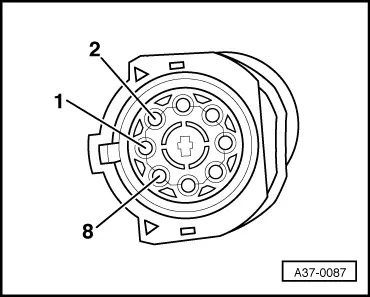

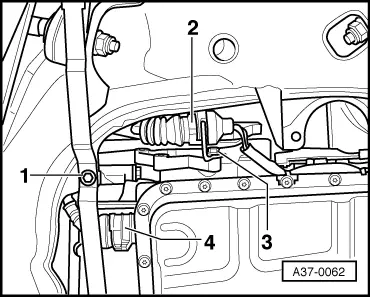

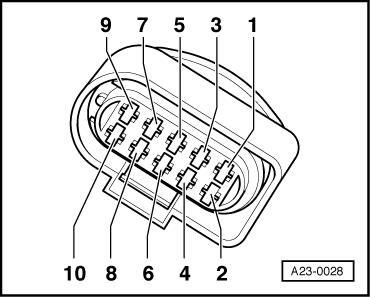

2. Checking power supply of 10-pin multi-function switch Checking is performed at connector (sockets) to gearbox control unit. |

|

|||||||||

Notes: If functional check and power supply of multi-function switch are OK, check wiring from automatic gearbox control unit -J217 to multi-function switch -F125 => Page 01-331 | |||||||||

|

|

|

3. Checking wiring from automatic gearbox control unit -J217 to 10-pin multi-function switch -F125

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Checking for gearbox with 10-pin connector at multi-function switch -F125

Checking for gearbox with 10-pin connector at multi-function switch -F125

Checking for gearbox with 10-pin connector at multi-function switch -F125

Checking for gearbox with 10-pin connector at multi-function switch -F125

1) Switch V.A.G 1526 to maximum ω range 2) Fuse for multi-function switch -F125 power supply | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

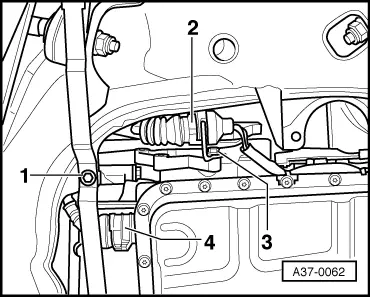

4. Checking wiring from automatic gearbox control unit -J217 to 10-pin connector at multi-function switch |

|

|||||||||||||||||||||||||||||||||||||||||||||

Checking is performed between 10-pin connector (sockets) and test box V.A.G 1598/20 at control unit connector.

Checking for gearbox with 10-pin connector at multi-function switch -F125

|