|

Self-diagnosis function

Self-diagnosis function

The automatic gearbox features electronic/hydraulic control.

The automatic gearbox control unit -J217 receives information from components which influence gear selection. The control unit uses this information to actuate the appropriate solenoid valves in the valve body. The solenoid valves pass the fluid pressure generated by the ATF pump to the clutches/brakes to be applied in each case.

Gearbox control unit fault recognition

The term "self-diagnosis" relates to the electrical/electronic section of the control system.

To enable the cause of the problem to be rapidly established in the event of failure of an electrical/electronic component or an open circuit in the wiring, the control unit is equipped with a fault memory.

Faults are detected by way of electrical signals. Faults occurring in monitored sensors or components are thus stored in the fault memory together with an indication of the type of fault and its location.

The first time a fault occurs, it is stored as being static. Once the fault is no longer present, it initially becomes a sporadic fault (SP).

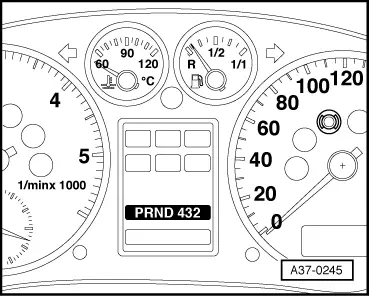

Faults stored in the fault memory as sporadic faults are displayed as "sporadic faults" on fault memory interrogation. "SP" then appears on the right of the display. Provided that the printer is switched on, "sporadic fault" is printed out after the fault designation.

Faults stored in the fault memory as sporadic faults are automatically erased after 40 engine cold starts (with subsequent gearbox warm-up).

Full use of the features offered by the self-diagnosis function can only be made using the vehicle diagnostic, testing and information system VAS 5051 or the fault reader V.A.G 1551 in mode 1 "Rapid data transfer".

For a list of functions covered by the vehicle diagnostic, testing and information system VAS 5051, refer to , List of available functions.

Gearbox control unit safety functions

In the event of failure of one or more components/sensors, automatic gearbox control unit -J217 activates appropriate substitute functions or emergency running programs. This ensures non-destructive operation of the automatic gearbox with the corresponding effects on gearshift function and quality.

If critical faults occur with automatic gearbox control unit -J217 active, the currently engaged gear is initially retained. As soon as the driving situation permits in terms of gearbox and driving safety, the automatic gearbox control unit -J217 activates "mechanical emergency running with active control unit".

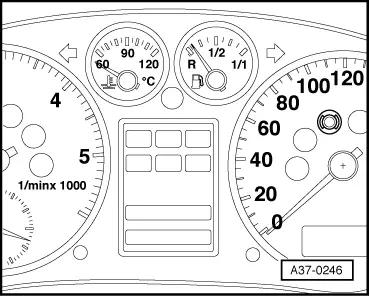

Mechanical emergency running with active control unit

|