A4 Mk1

|

Removing and installing engine

Removing

Notes:

Vehicles with automatic gearbox:

|

|

|

|

All models:

|

|

|

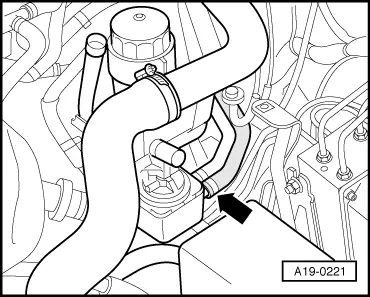

Attention:

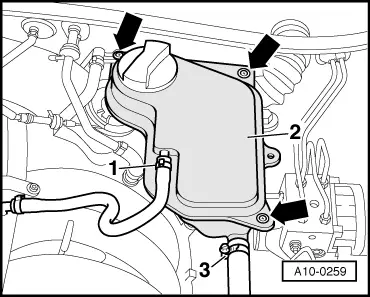

Hot vapour may escape when opening expansion tank. Cover cap with cloth and open carefully.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

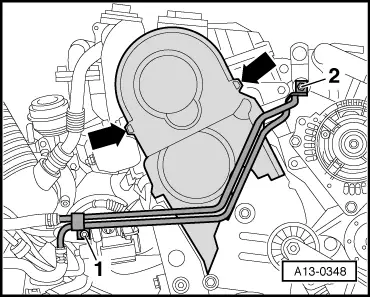

Vehicles with automatic gearbox: Note: Observe rules for cleanliness when working on automatic gearbox:

|

|

|

|

Vehicles with air conditioner:

|

|

|

|

All models:

|

|

|

|

|

|

|

|

|

|

|

|

|

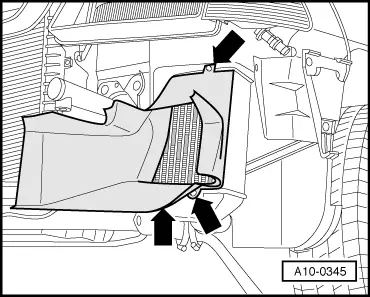

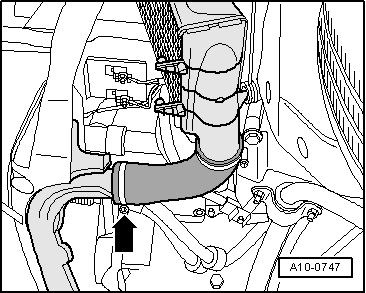

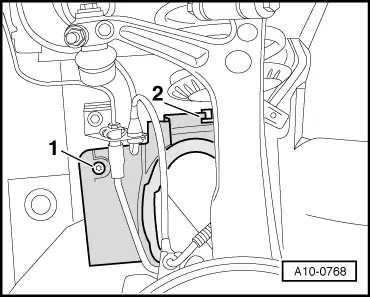

Vehicles with air conditioner: Attention:

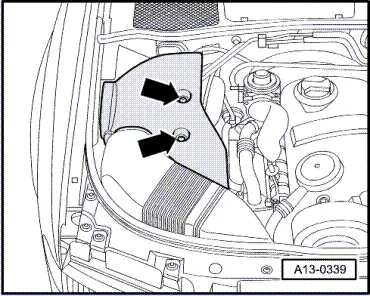

Never open refrigerant circuit of air conditioner. Note: To prevent damage to condenser and refrigerant lines/hoses ensure that lines and hoses are not stretched, kinked or bent.

Note: Protect wing panel from damage. |

|

|

|

All models:

|

|

|

|

Attention:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Notes:

|

|

|

|

|

|

|

Vehicles with automatic gearbox:

|

|

|

|

All models:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

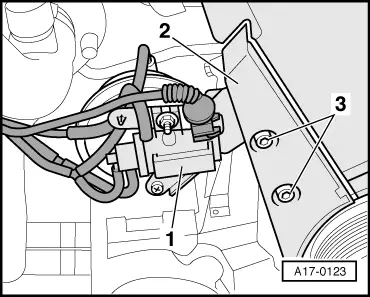

Vehicles with manual gearbox:

|

|

|

|

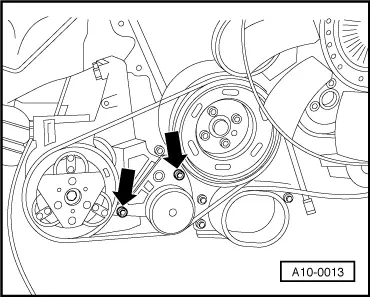

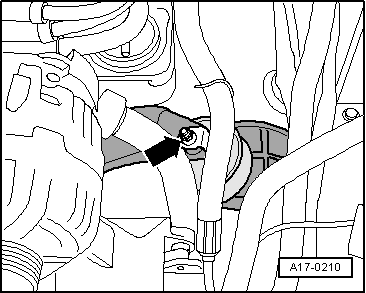

All models: Note: Before removing, mark direction of ribbed belt with chalk or felt-tipped pen. Running a used belt in the opposite direction could destroy it.

|

|

|

|

|

|

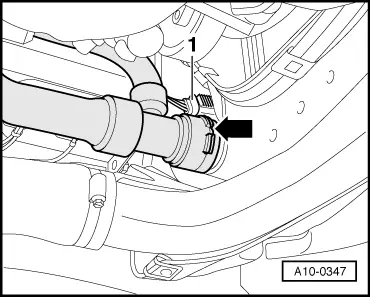

Note: To avoid damage, decoupling element of exhaust system is never to be kinked by more than 10 °. |

|

|

|

Vehicles with air conditioner: Attention:

Never open refrigerant circuit of air conditioner. Note: Before removing, mark direction of ribbed belt with chalk or felt-tipped pen. Running a used belt in the opposite direction could destroy it.

|

|

|

|

All models:

|

|

|

|

|

|

|

|

|

|

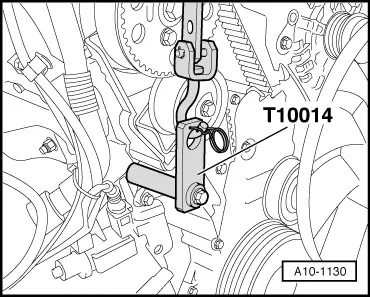

Vehicles with automatic gearbox:

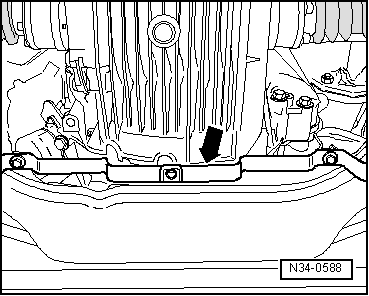

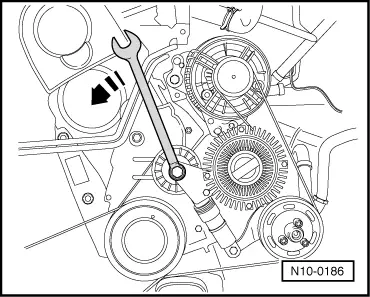

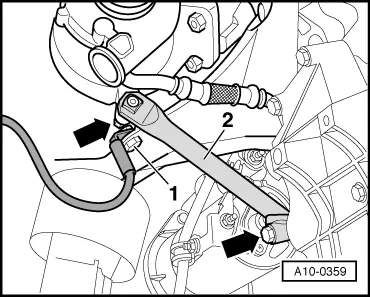

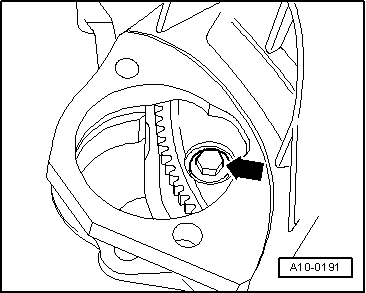

Note: When loosening torque converter bolts, counterhold crankshaft by applying spanner to central bolt on vibration damper. |

|

|

|

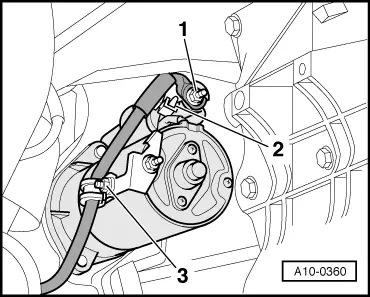

All models:

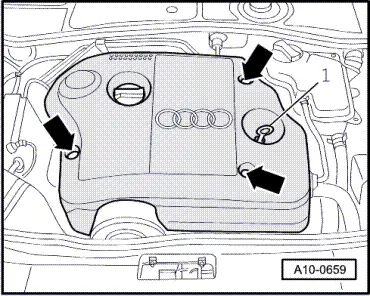

Note: Different mounting holes are provided for different engine versions.

|

|

|

|

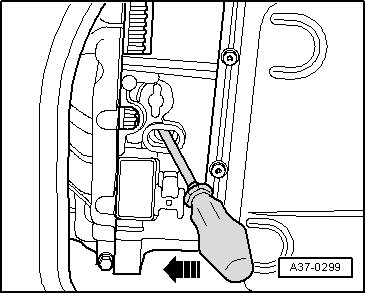

Note: If the bolts will not unscrew:

Attention:

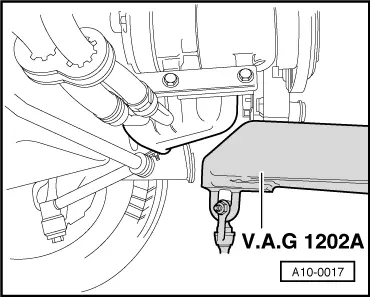

To avoid injury, ensure the support is secure. |

|

|

|

|

|

Notes:

|

|

|

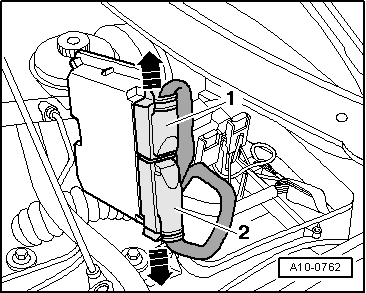

Note: The coolant hoses can remain connected to the lines.

|

|

|

|

|

|

|

|

|

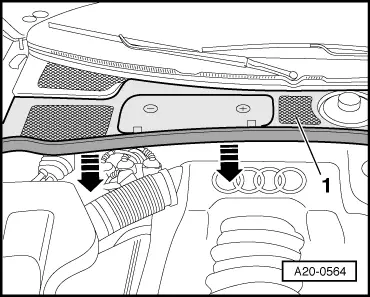

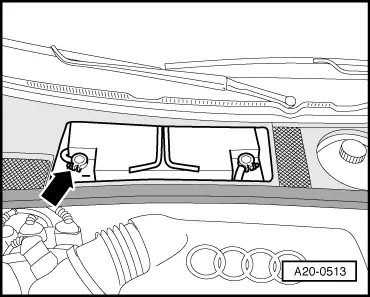

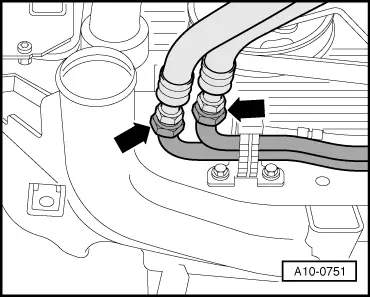

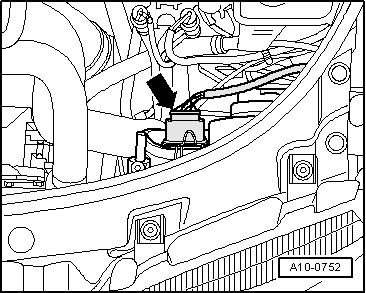

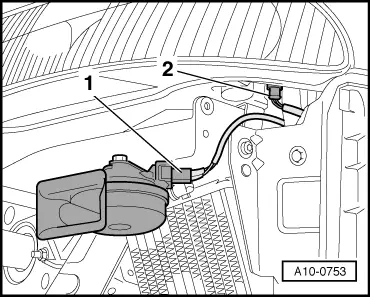

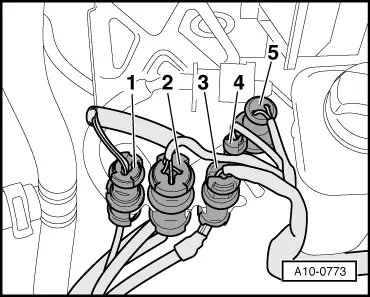

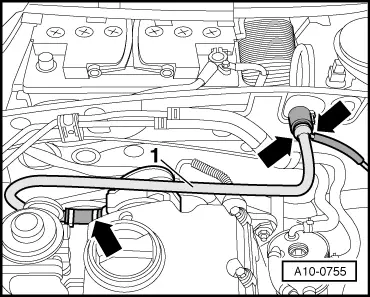

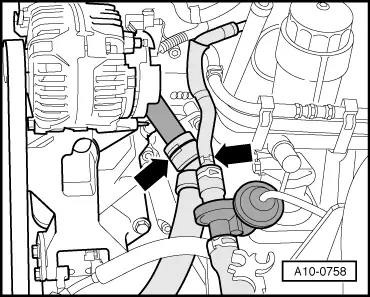

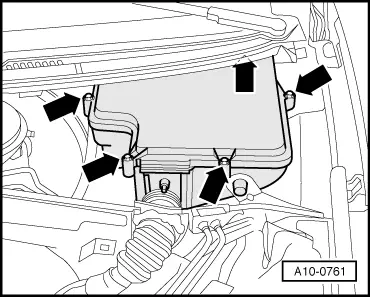

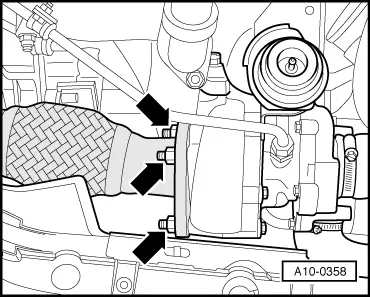

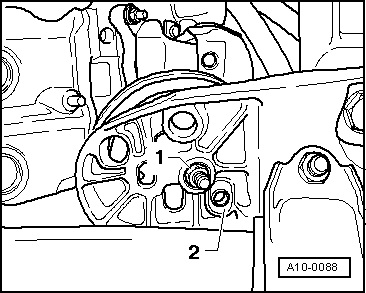

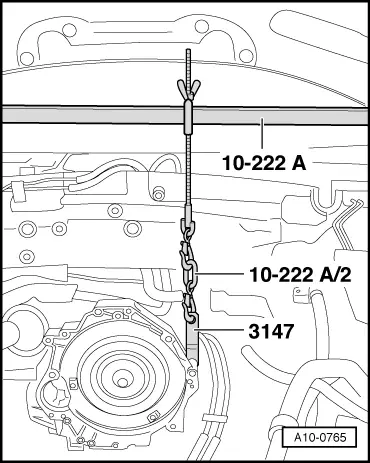

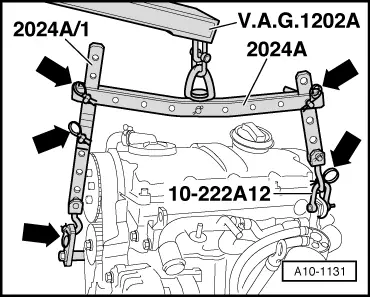

Note: For alignment with centre of gravity of assembly, holes of support hook rails must be positioned as shown. Attention:

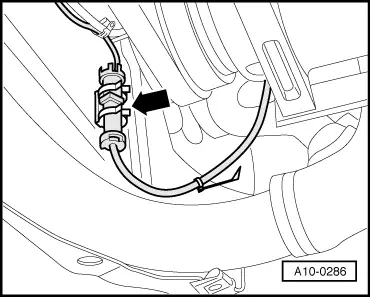

Support hooks and setting pins at lifting tackle must be secured with fasteners (arrows in Fig.).

Note: Check that all hoses and other connections between engine and body have been detached.

Note: Make sure no wires are damaged at the top on the bulkhead. |

|

|

|

Vehicles with automatic gearbox:

All models:

Vehicles with automatic gearbox:

|