A4 Mk1

|

Dismantling and assembling engine

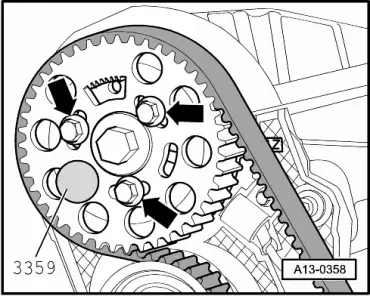

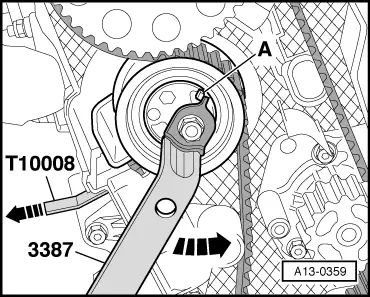

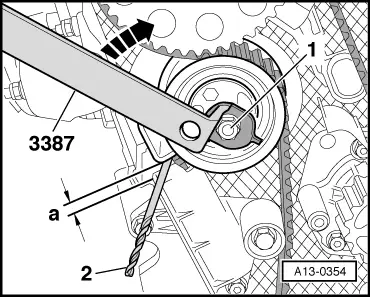

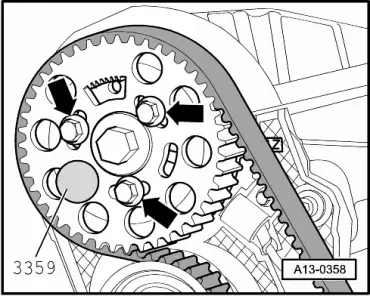

Removing and installing toothed belt

|

|

|

|

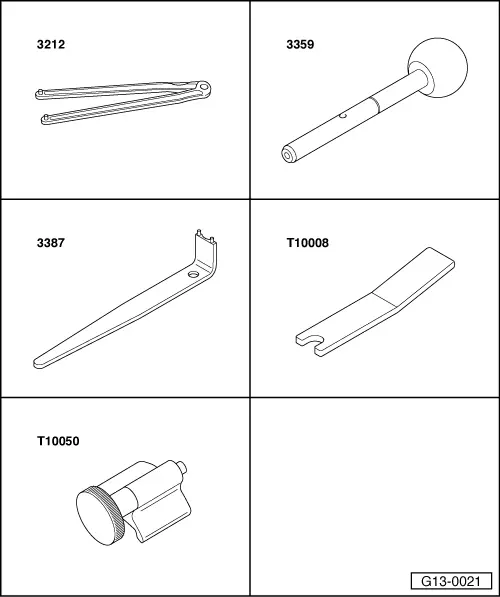

Special tools and workshop equipment required

=> Parts List |

|

|

|

Removing

|

|

|

|

|

|

|

|

|

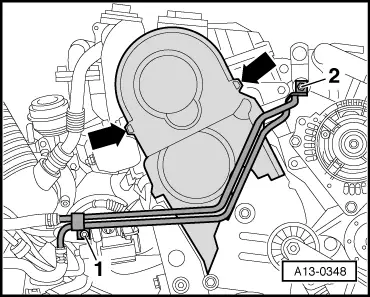

Note: The coolant hoses can remain connected to the lines.

|

|

|

|

|

|

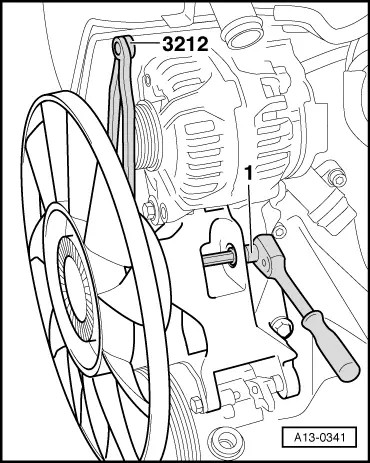

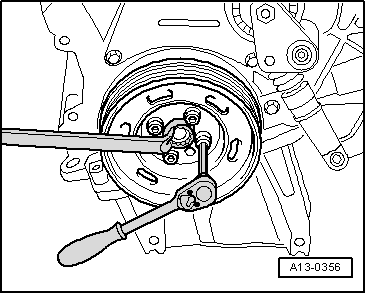

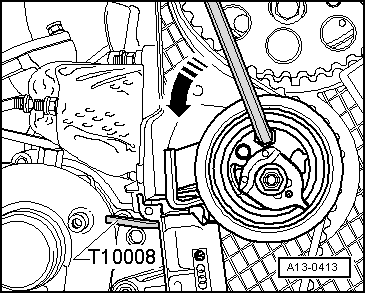

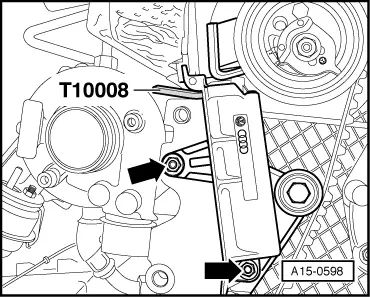

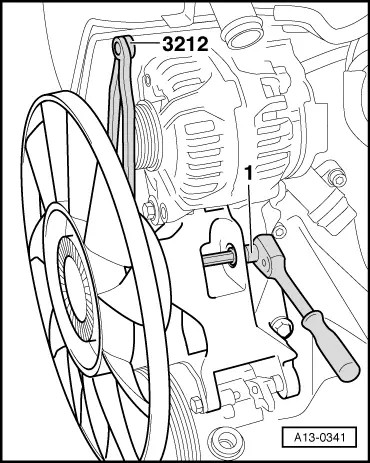

Note: Provide support with box wrench at central bolt when unfastening and tightening vibration damper. |

|

|

|

|

|

|

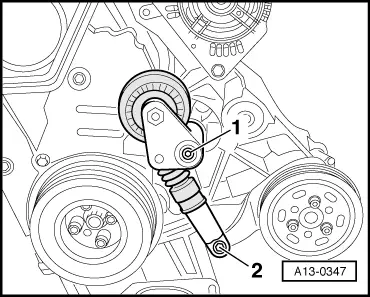

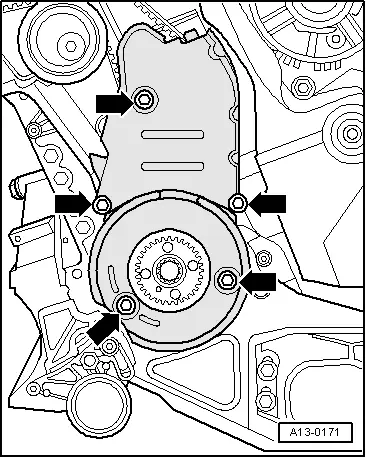

Attention:

Engine is only to be cranked by turning crankshaft in direction of engine rotation (clockwise). Note: Use central bolt of crankshaft as application point for cranking engine.

Notes:

|

|

|

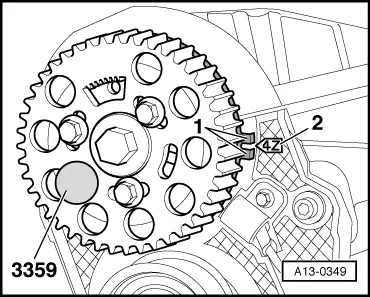

Notes:

|

|

|

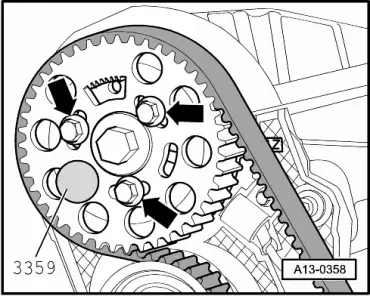

Notes:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

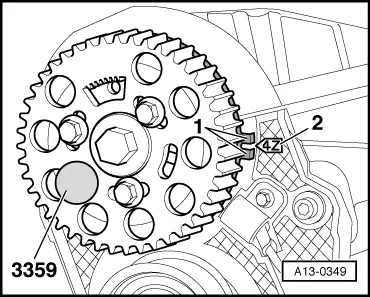

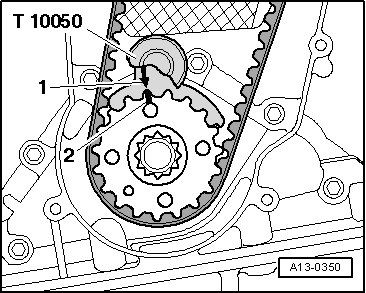

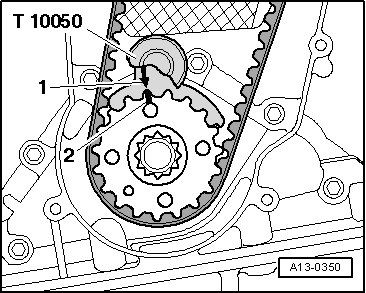

Checking valve timing

Notes:

|

|

|

Notes:

|

|

|

|

If hub cannot be locked:

Attention:

Engine is only to be cranked by turning crankshaft in direction of engine rotation (clockwise).

|

|

||||||||||||||||||||||||||||||||||

Tightening torques

1) 45°corresponds to one eighth of a turn 2) Insert with locking fluid1; => Parts List 3) Replace bolts 4) 90°corresponds to quarter of a turn | ||||||||||||||||||||||||||||||||||