|

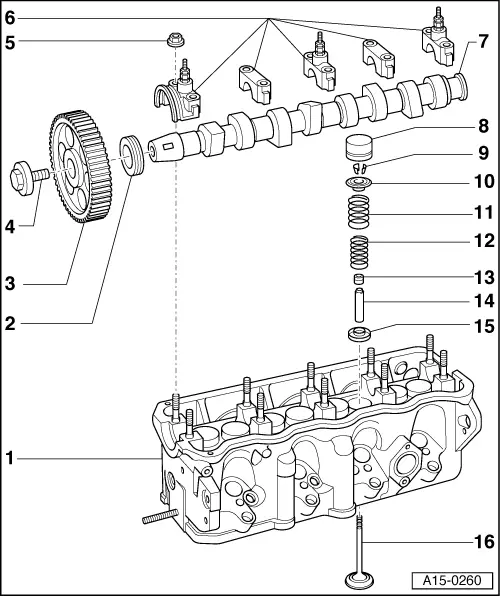

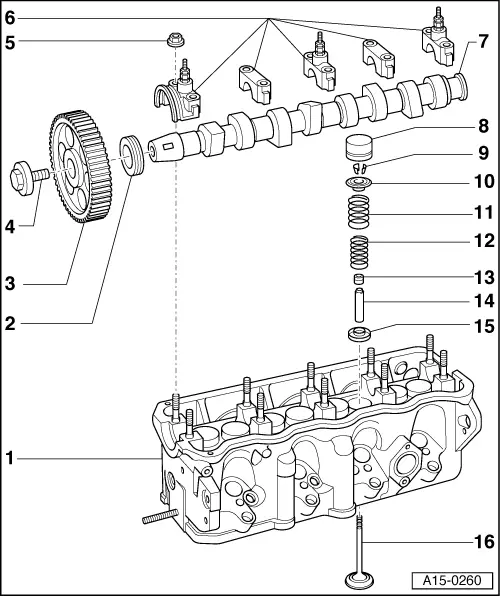

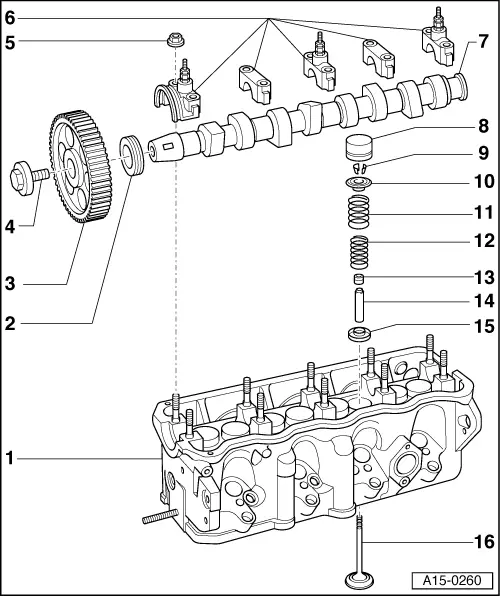

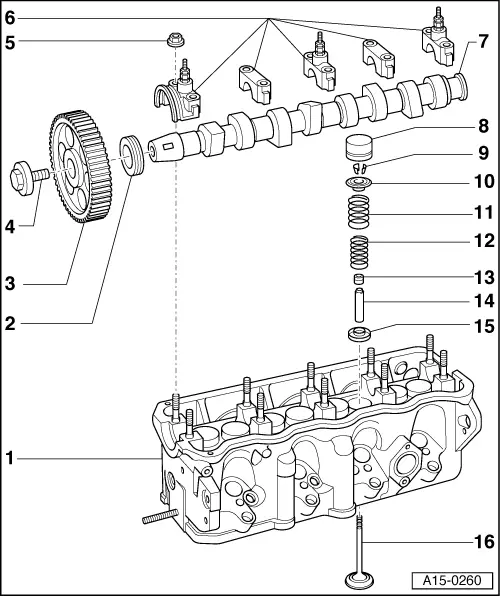

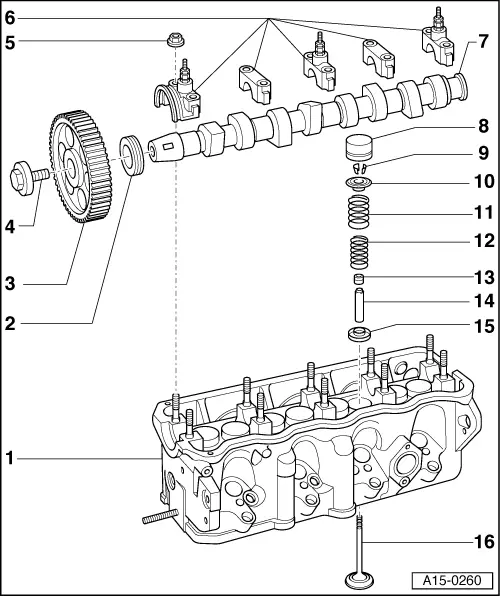

Servicing valve gear

Servicing valve gear

Notes:

-

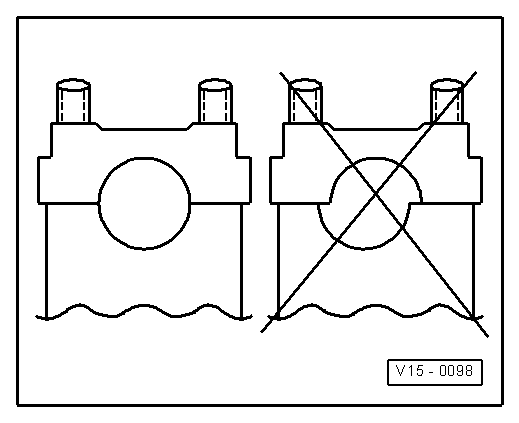

◆ Cylinder heads with cracks between valve seats can still be used without a reduction of service life, if cracks are slight, max. 0.5 mm wide.

-

◆ After installing the camshaft, wait for about 30 minutes before starting the engine. Hydraulic valve compensation elements have to settle (otherwise valves will strike pistons).

-

◆ After working on the valve gear, turn the engine carefully at least 2 rotations to ensure that none of the valves make contact when the starter is operated.

-

◆ Renew all gaskets and seals.

-

◆ Note current specifications when using sealant:

=> Parts List

|