A4 Mk1

|

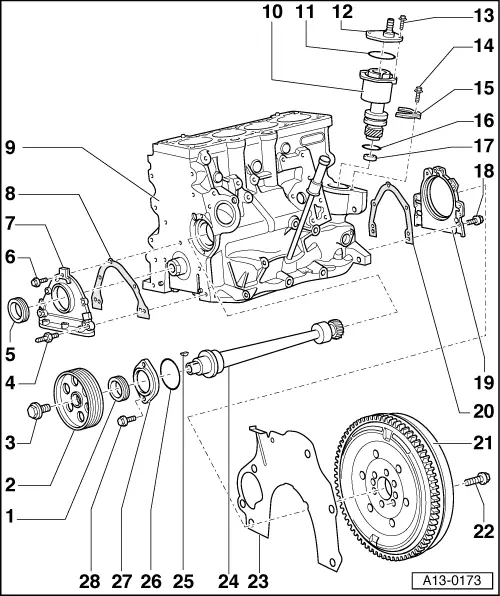

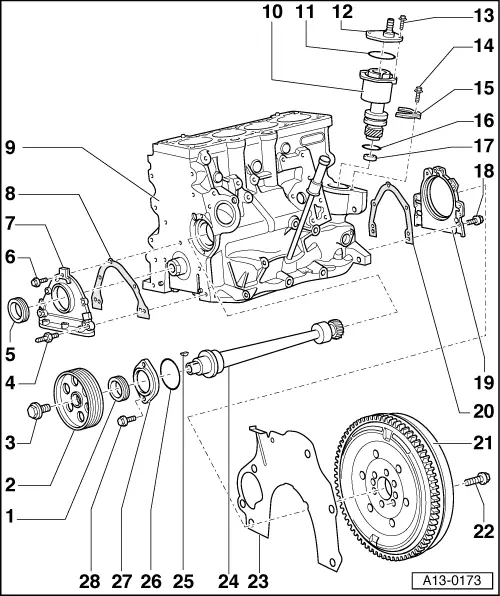

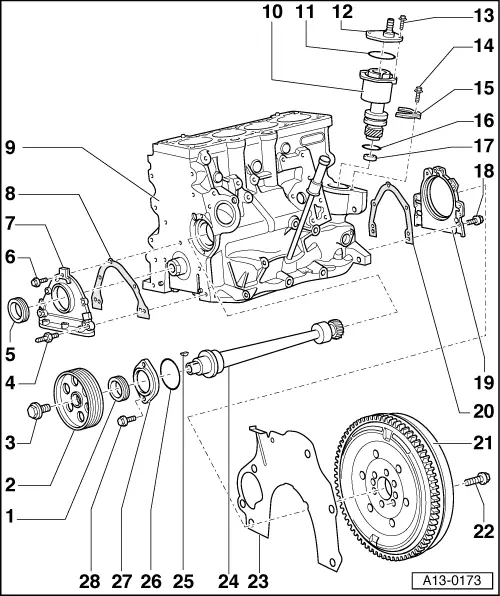

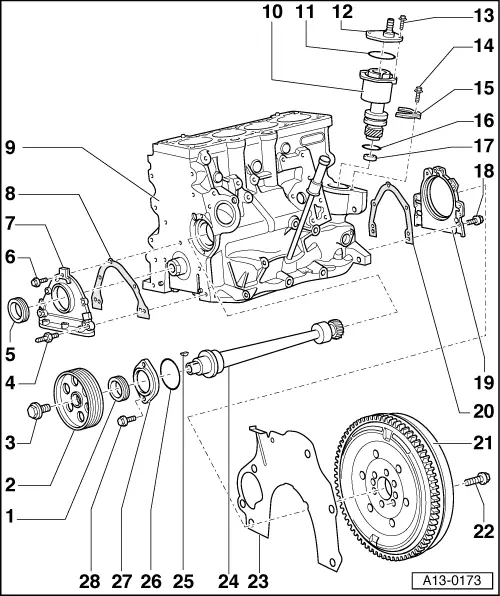

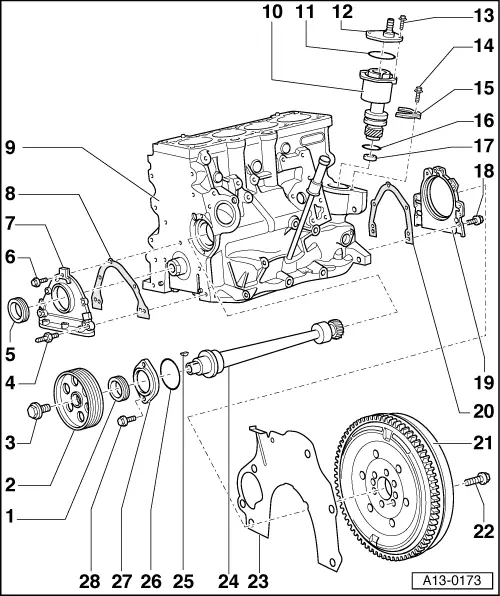

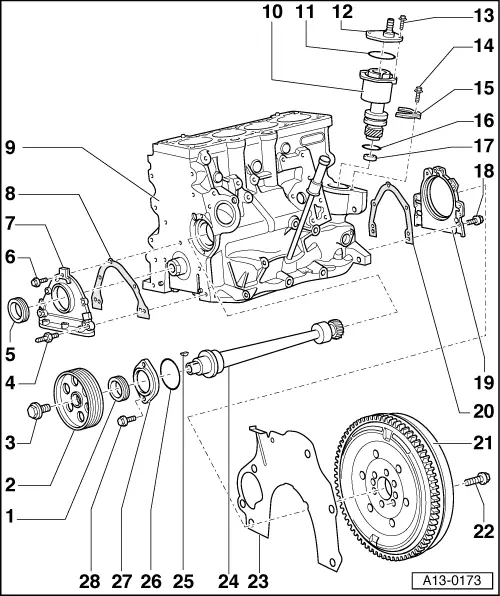

Removing and installing sealing flanges and flywheel/drive plate

Removing and installing sealing flanges and flywheel/drive plate

|

|

|

|

Note: For repairs to the clutch:

|

|

|

=> Parts List |

|

|

|

|

=> Parts List

|

|

|

|

|

|

|

|

|

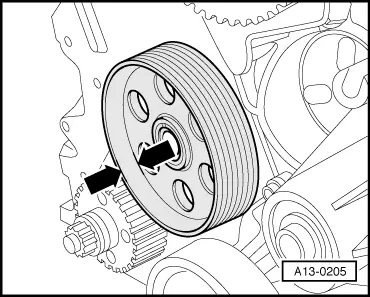

→ Fig.1 Installation position of intermediate shaft sprocket

|