| –

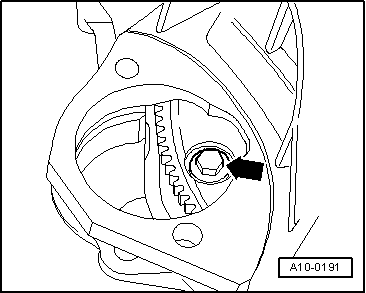

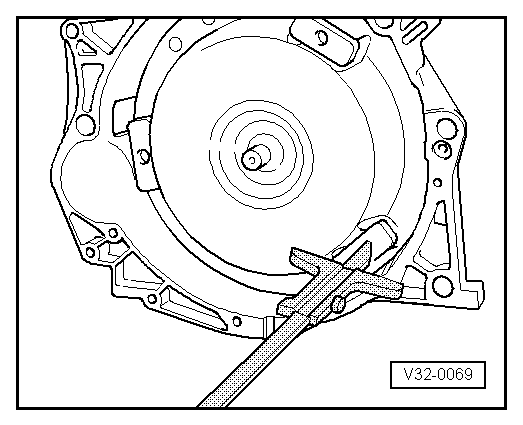

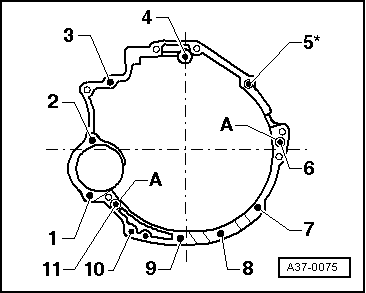

| Before bringing engine and gearbox together, turn torque converter and drive plate on engine so that the holes for one securing bolt are in line with the opening for the starter motor -arrow-. |

Caution | Risk of damage to gearbox if torque converter is installed incorrectly. |

| t

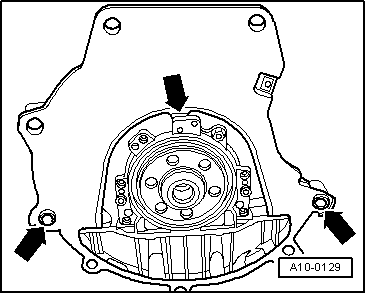

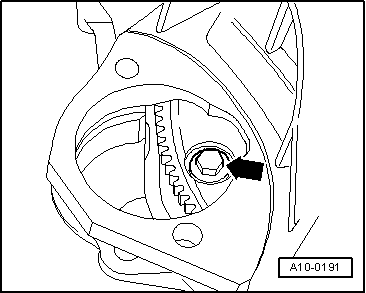

| Before and during tightening of bolts securing engine to gearbox, continually check that the torque converter behind the drive plate can be turned. |

| t

| If the torque converter cannot be turned, the drive lugs of the ATF pump and consequently the gearbox will be damaged when the bolts are finally tightened. |

|

| All vehicles (continued): |

| –

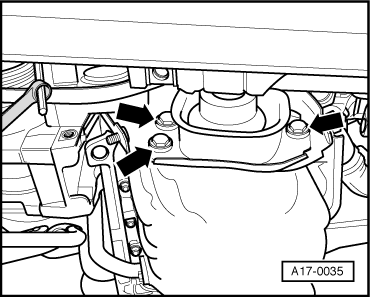

| Join engine onto gearbox and screw in one securing bolt (tighten hand-tight). |

| –

| Slacken spindle of support bracket -10 - 222 A-. |

| –

| Lower engine, inserting studs of engine mountings into consoles for engine mountings. |

| –

| Install engine mountings free of stress. To do so, shake engine before tightening engine mountings. |

|

|

|

Note

Note

Note

Note Note

Note

Caution

Caution