| –

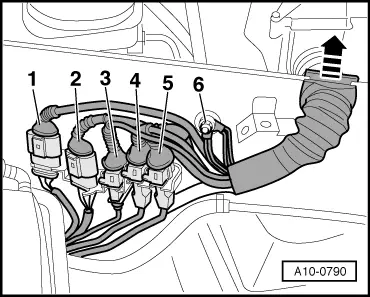

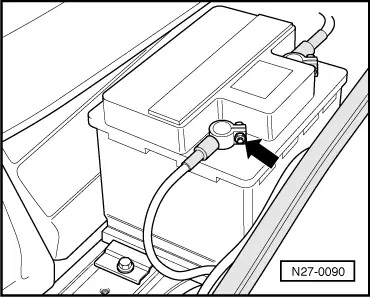

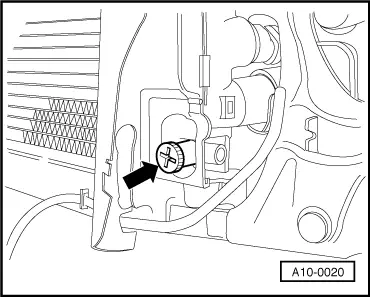

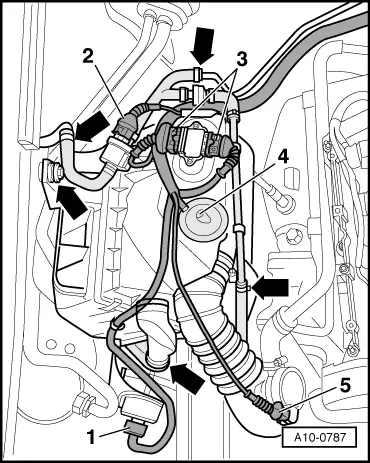

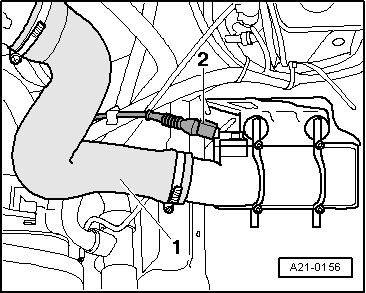

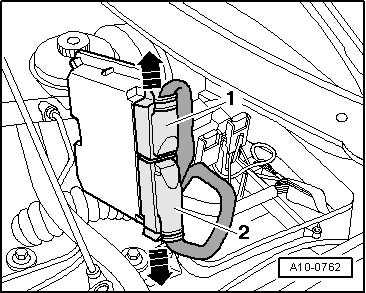

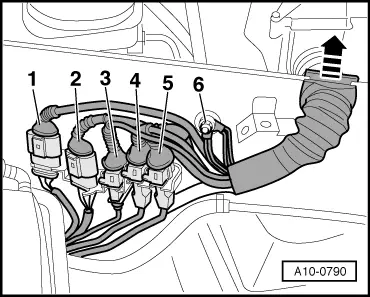

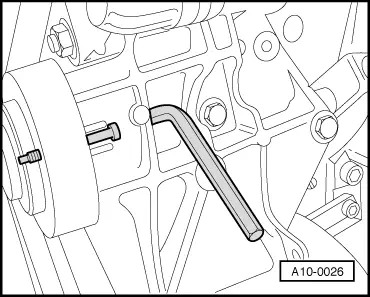

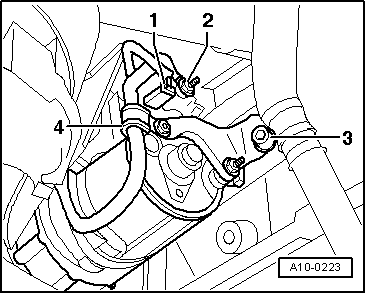

| Unscrew earth wire -6-. |

| –

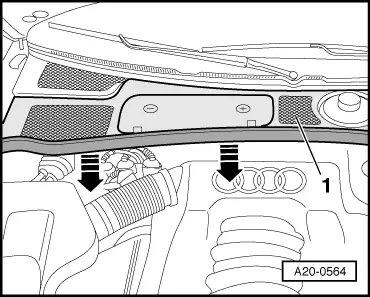

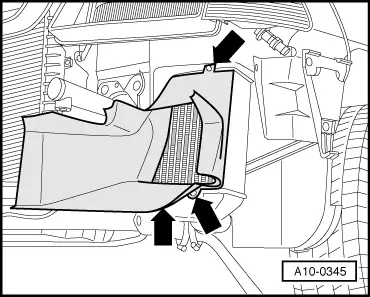

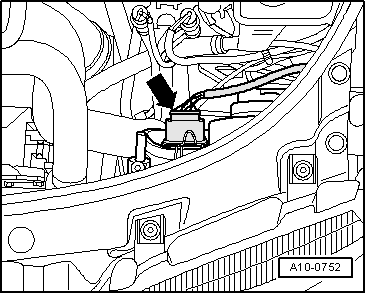

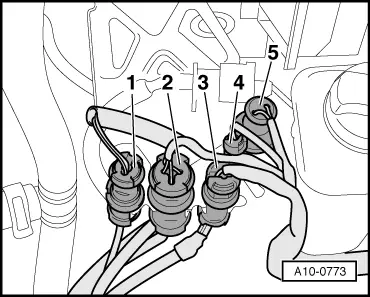

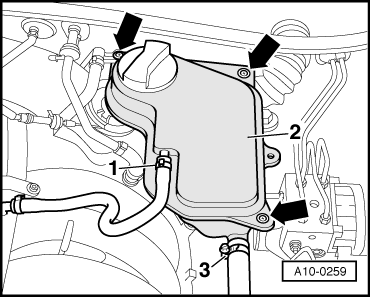

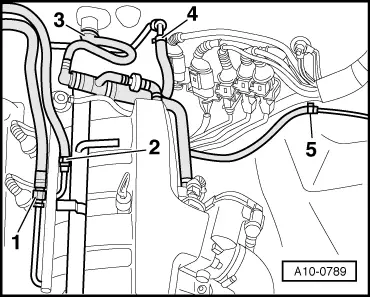

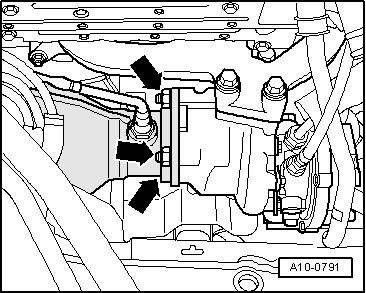

| Detach electrical connectors -1 ... 5- from bracket. |

| –

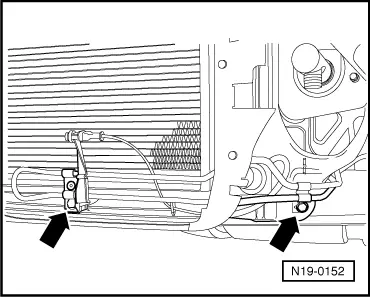

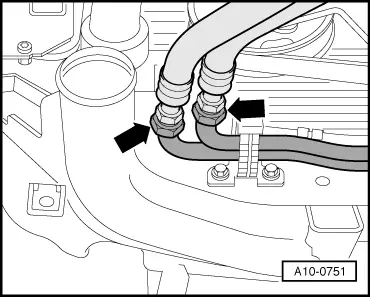

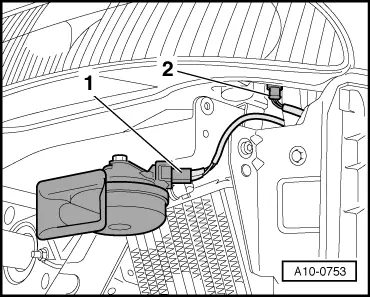

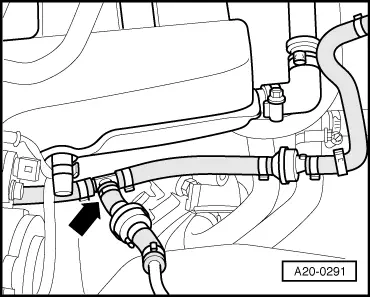

| Unplug electrical connectors: |

| 1 - | For Lambda probe after catalytic converter -G130- (brown, vehicles with 2 Lambda probes) |

| 2 - | For Lambda probe -G39- (before catalytic converter; black) |

| –

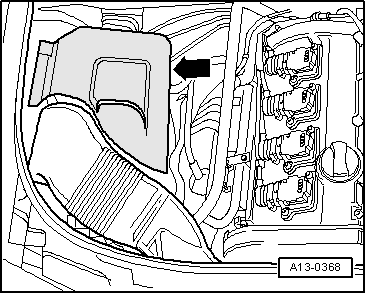

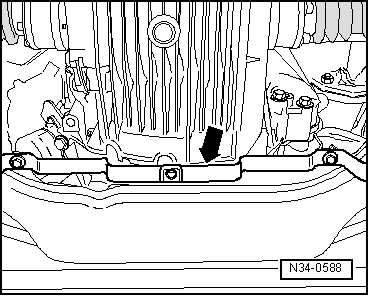

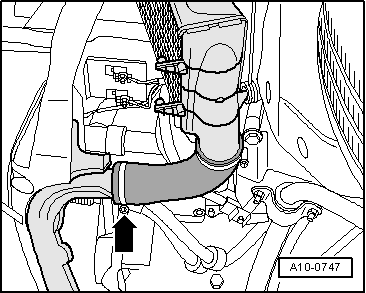

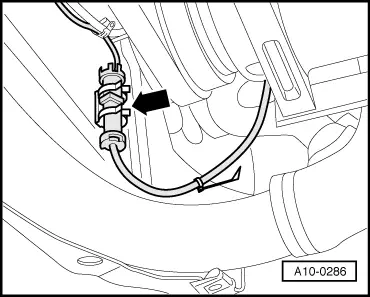

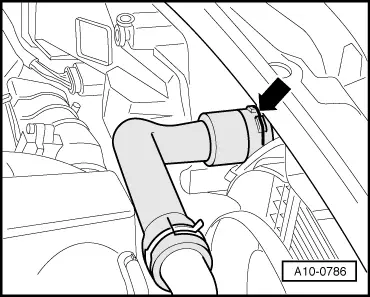

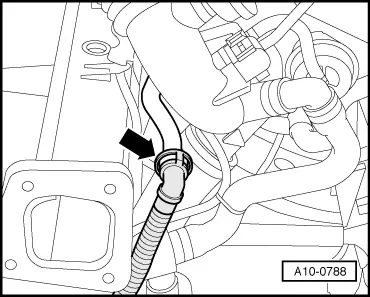

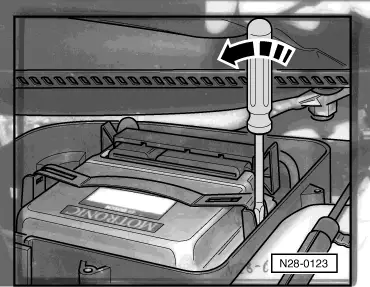

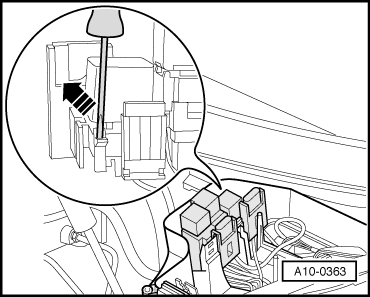

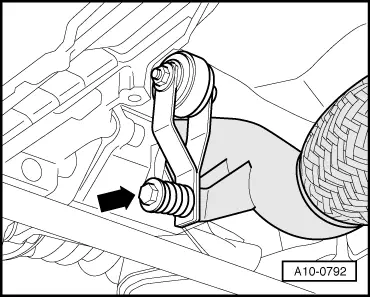

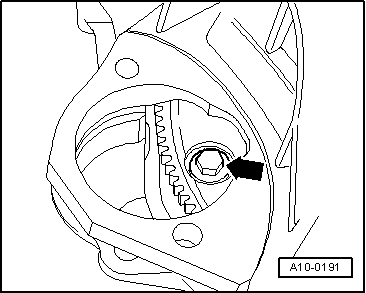

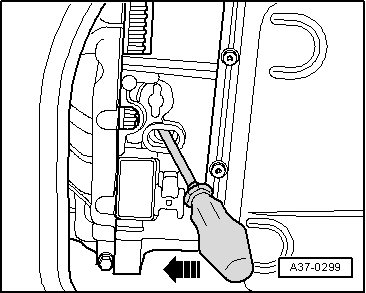

| Unhook wiring harness -arrow- and move it clear. |

| –

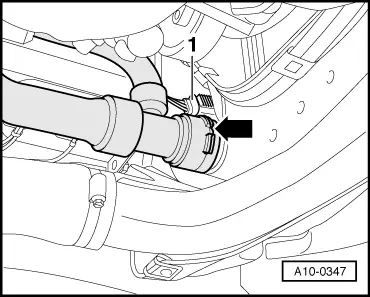

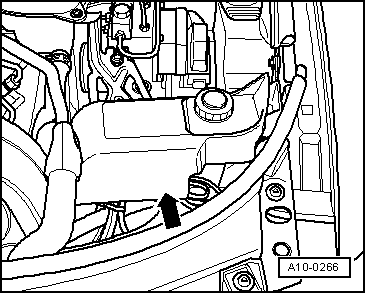

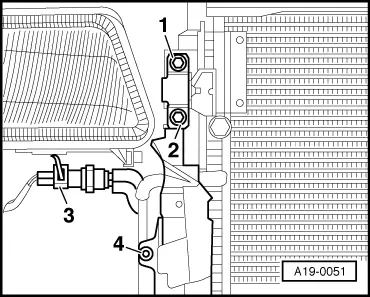

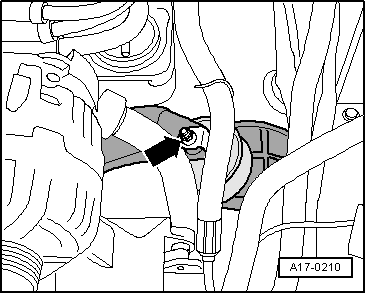

| Unplug electrical connector from speedometer sender -G22- on left of gearbox, and move wire clear. |

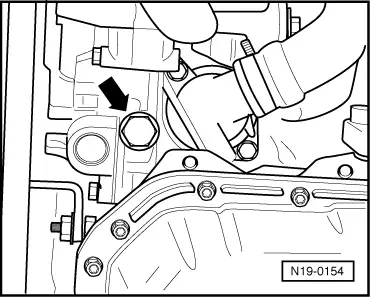

| Vehicles with manual gearbox: |

| –

| Unplug electrical connector for reversing light switch -F4- from gearbox and move electrical wire clear. |

| All vehicles (continued): |

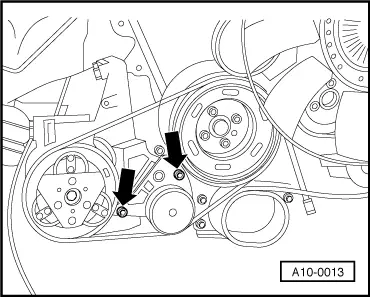

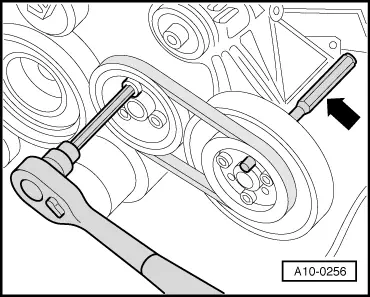

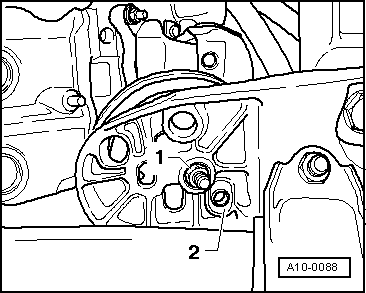

Caution | If a used belt runs in the opposite direction when it is refitted, this can cause breakage. |

| Before removing, mark direction of rotation of poly V-belt with chalk or felt-tipped pen for re-installation. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Caution

Caution WARNING

WARNING