| –

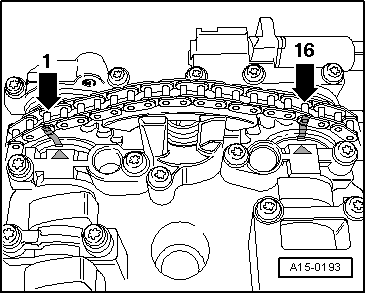

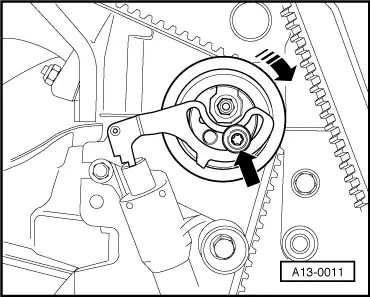

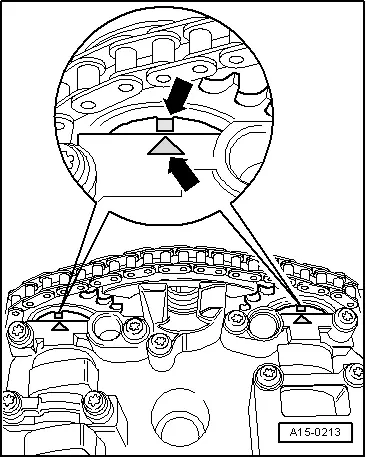

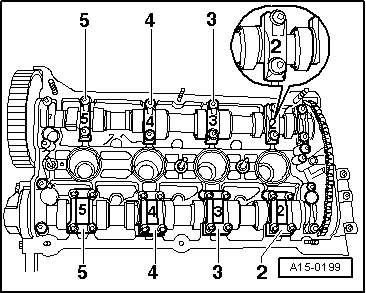

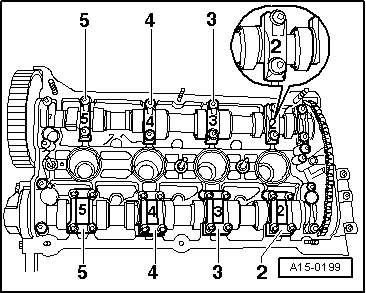

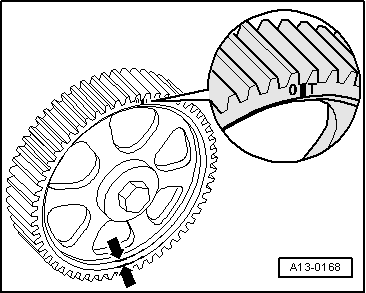

| Install camshaft sprocket. |

| l

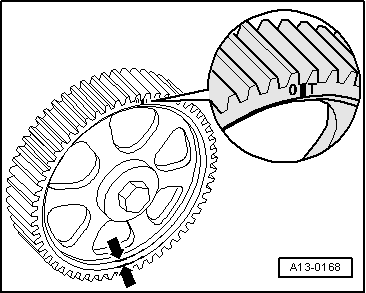

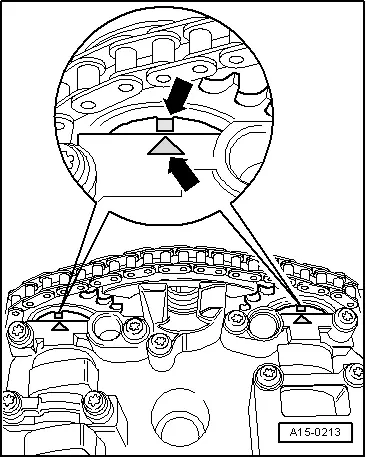

| Installation position: The thinner web of the camshaft sprocket faces outwards -arrows- and the marking for “TDC” is visible. |

| –

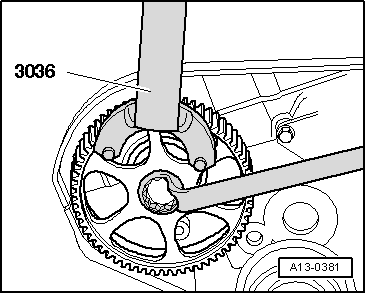

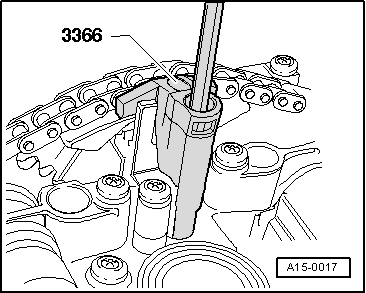

| Tighten camshaft sprocket bolt using counterhold tool -3036-. |

| –

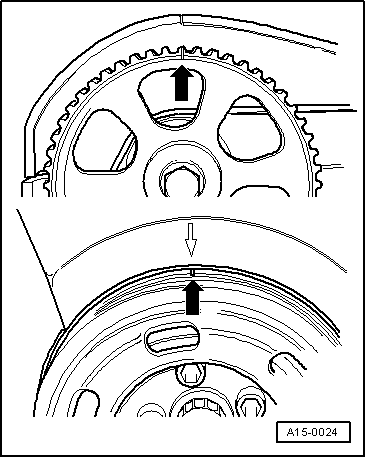

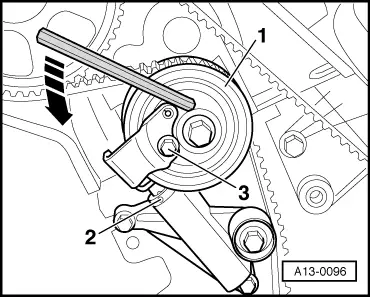

| Turn crankshaft approx. 45° clockwise to “TDC” position via toothed belt sprocket bolt. |

| –

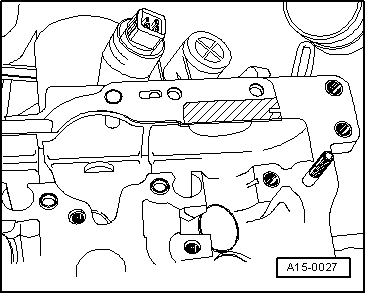

| Install toothed belt (adjust valve timing): vehicles up to 05.1999 → Anchor, vehicles from 06.1999 onwards → Anchor. |

Note | t

| After installing camshafts, wait for approx. 30 minutes before starting engine. Hydraulic valve compensation elements have to settle (otherwise valves will strike pistons). |

| t

| After working on the valve gear, turn the engine carefully at least 2 rotations to ensure that none of the valves make contact when the starter is operated. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution