A4 Mk1

|

Removing and installing engine

Installing

Installation is carried out in the reverse order, when doing this note the following: Note: When performing repairs, renew seals, gaskets, self-locking nuts and bolts which have a specified tightening angle.

Vehicles with manual gearbox

Vehicles with automatic gearbox

=> Parts catalogue

|

|

|

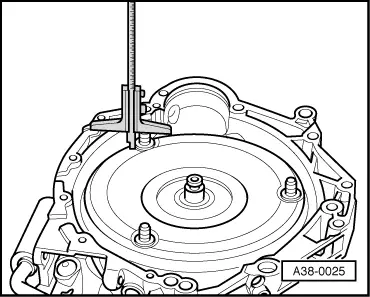

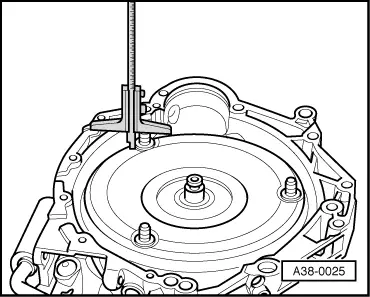

Checking position of torque converter → If the torque converter has been installed correctly, the distance between the joint surface on the torque converter bellhousing and the bottom contact surface on the torque converter studs should be approx 24.5 mm (automatic gearbox 01N). |

|

|

|

→ If the torque converter has not been fully inserted, this distance will be approx. 13 mm. Important

If the torque converter is not installed correctly, the torque converter drive plate or the ATF pump will be seriously damaged when the gearbox is joined to the engine.

All models

Notes:

=> Current flow diagrams, Electrical fault-finding and Fitting locations

=> Radio operating instructions

Note: Faults will have been stored in the memory because connectors have been unplugged. Therefore interrogate and erase fault memory after installing engine.

|