A4 Mk1

|

|

|

|

|

|

|

|

|

|

|

|

|

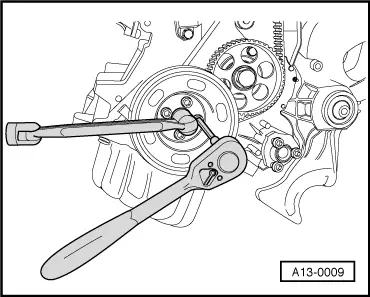

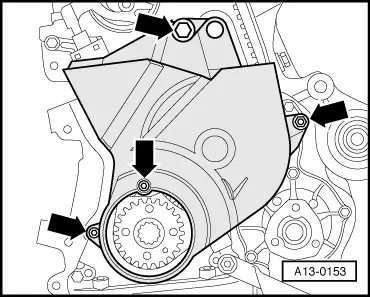

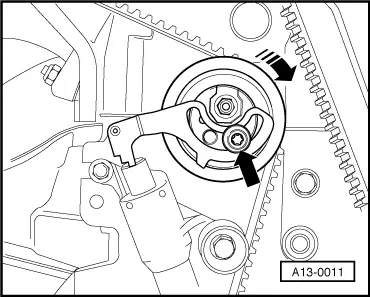

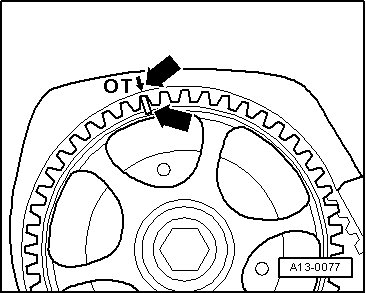

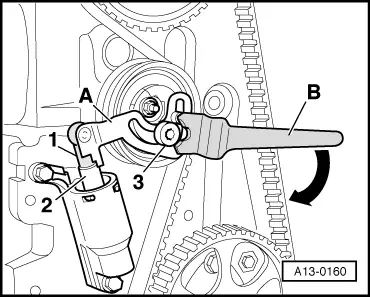

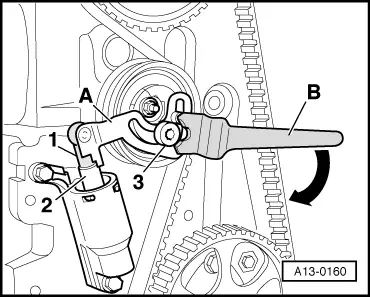

Installing (adjusting valve timing) Notes: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

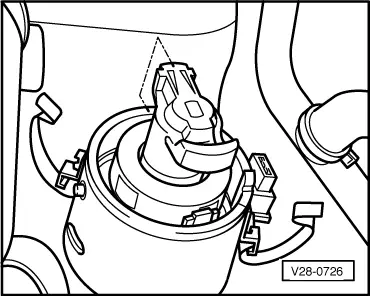

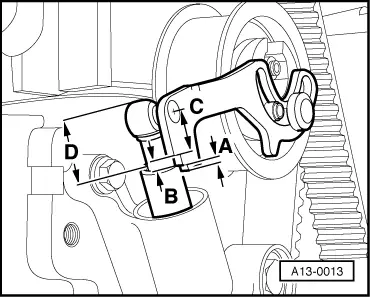

Note: If the end of the piston is in area -A-, this corresponds to a distance -D- of 25 ... 29 mm. |

|

|||||||||||||||||||

Tightening torques

1) Bolt strength rating 10.9 | |||||||||||||||||||