| –

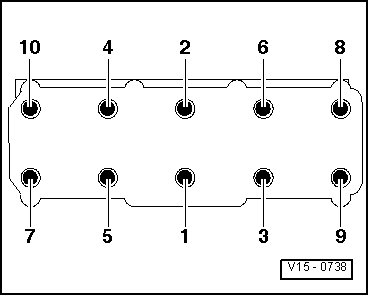

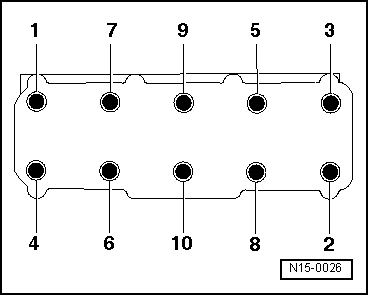

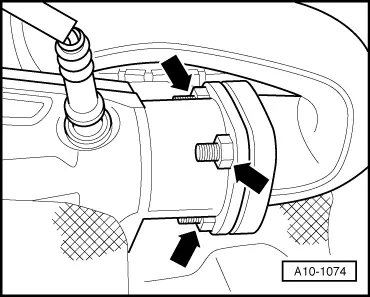

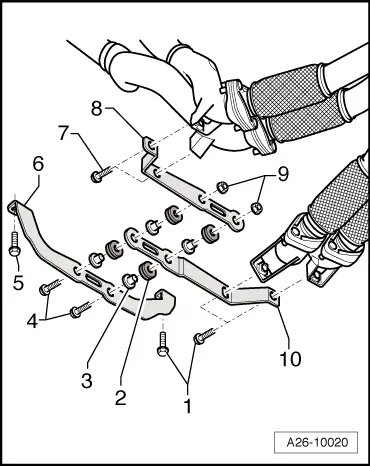

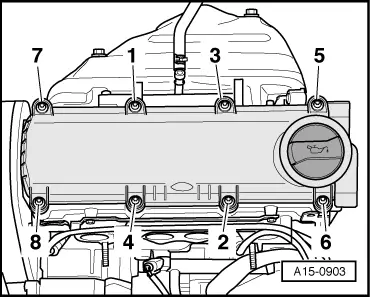

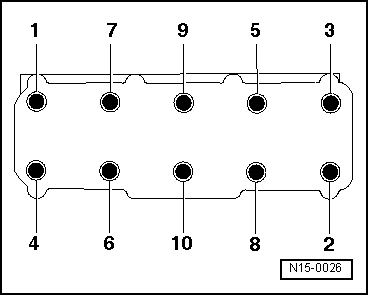

| Remove cylinder head bolts in the sequence: -1 ... 10-. |

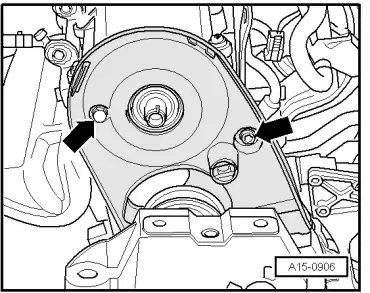

Note | Use special wrench, long reach -T10070- to remove cylinder head bolts. |

| –

| Remove the cylinder head with the assistance of a 2nd mechanic. |

Note | t

| Renew the cylinder head bolts. |

| t

| Renew self-locking nuts and bolts when performing assembly work. |

| t

| Renew bolts which are tightened to a specified angle as well as oil seals and gaskets. |

| t

| If repairing, carefully remove any remaining gasket material from the cylinder head and cylinder block. Ensure that no long scores or scratches are made on the surfaces. |

| t

| Carefully remove any remaining emery and abrasive material. |

| t

| No oil or coolant must be allowed to remain in the blind holes for the cylinder head bolts in the cylinder block. |

| t

| Do not remove new cylinder head gasket from packaging until it is ready to be fitted. |

| t

| Handle gasket very carefully. Damage to the silicone coating or the indented area will lead to leaks. |

| t

| Cylinder heads which have cracks between the valve seats or between a valve seat insert and the spark plug thread can be re-installed without reducing service life, provided the cracks are only slight and do not exceed a maximum of 0.3 mm in width, and no more than the first 4 turns of the spark plug threads are cracked. |

| t

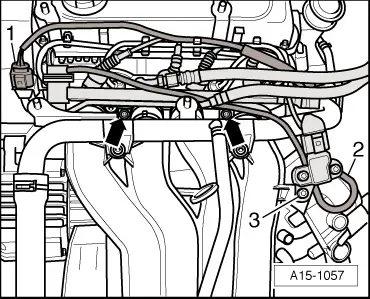

| When installing an exchange cylinder head with fitted camshaft, the contact surfaces between roller rocker fingers and cams must be oiled after installing the head. |

| t

| The plastic protectors fitted to protect the open valves should not be removed until the cylinder head is ready to be fitted. |

| t

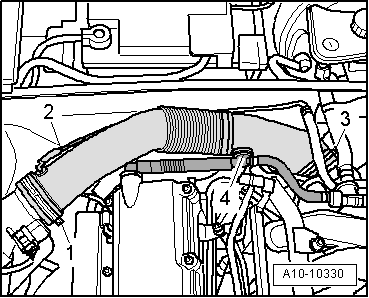

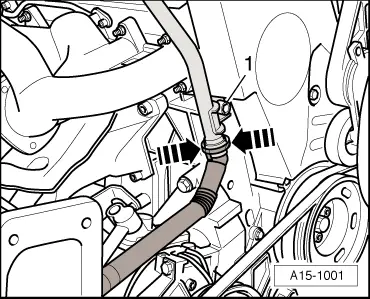

| Secure all hose connections with the correct type of hose clips (same as original equipment) → Parts catalogue. |

| t

| Fit all heat insulation sleeves in the original position when installing. |

| t

| Fit all cable ties in the original positions when installing. |

| t

| After working on the valve gear, turn the engine carefully at least 2 rotations by hand to ensure that none of the valves make contact when the starter is operated. |

| t

| When fitting a new cylinder head or cylinder head gasket, drain off all the old coolant and refill with new coolant. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note

Caution

Caution