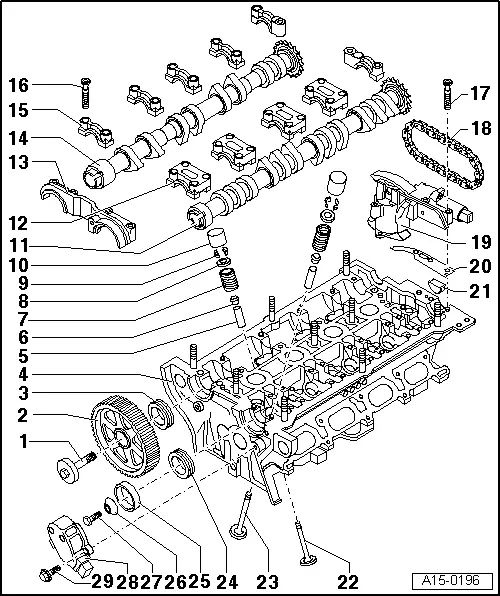

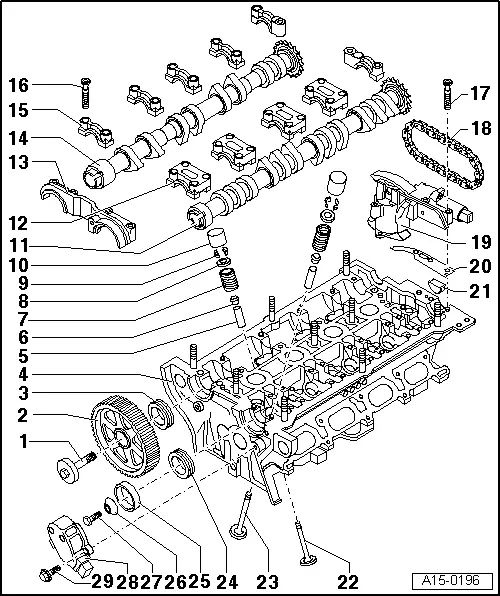

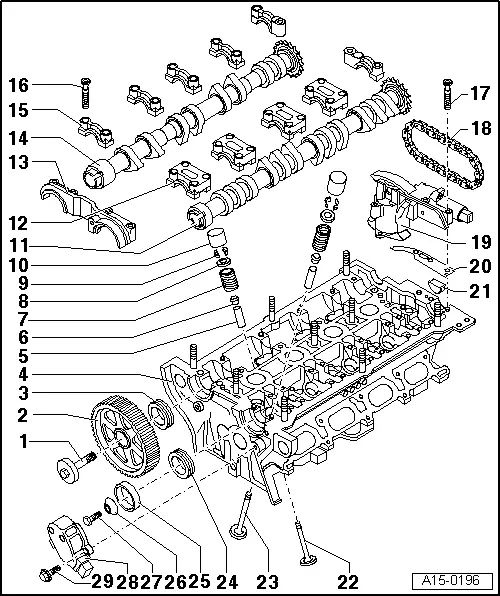

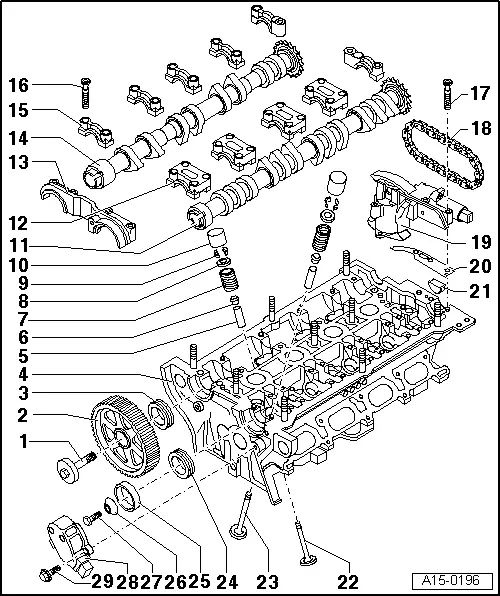

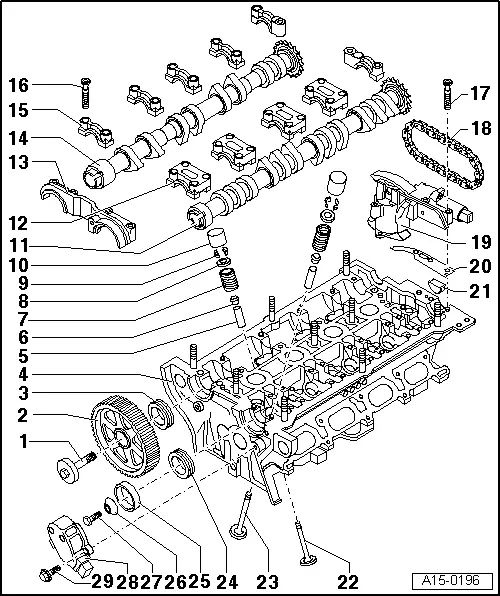

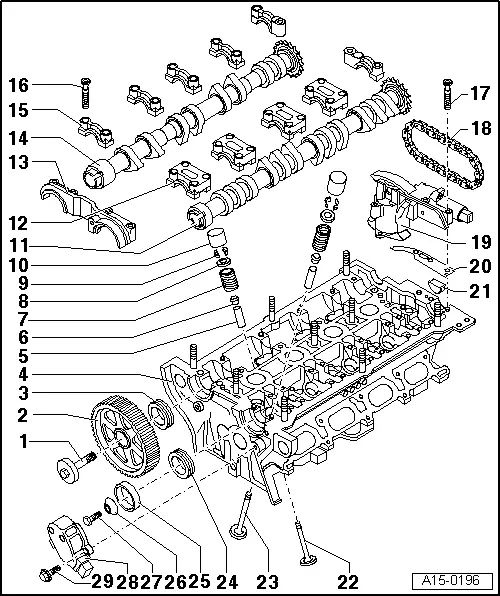

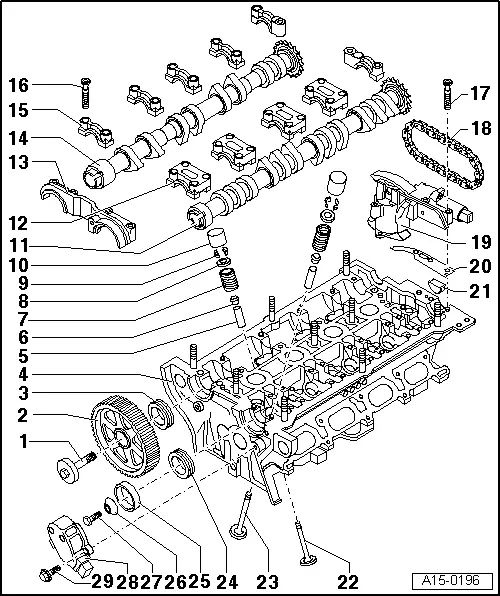

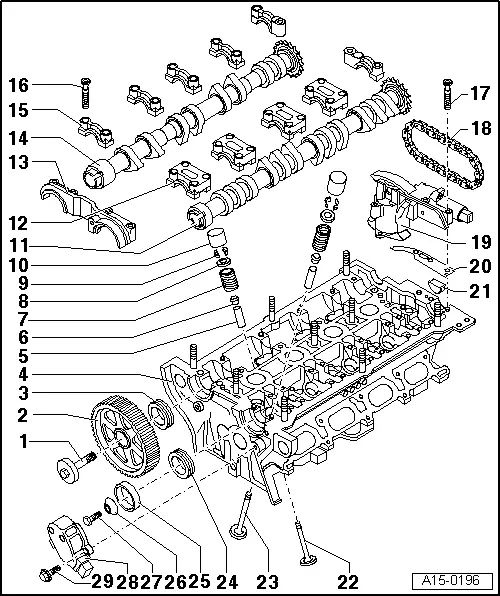

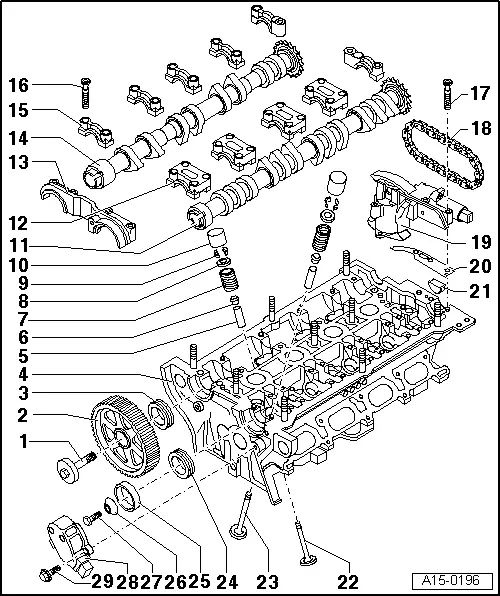

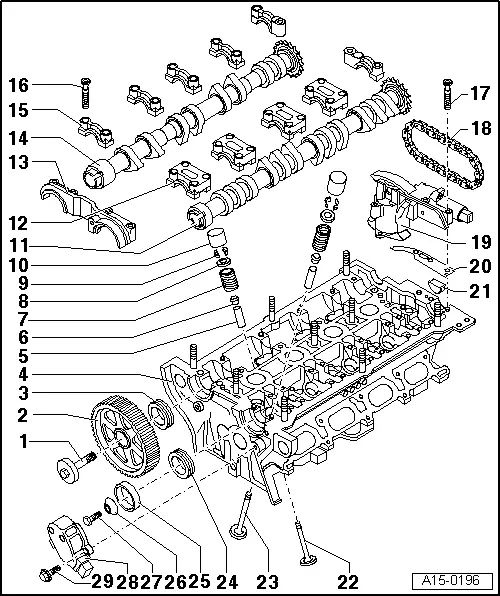

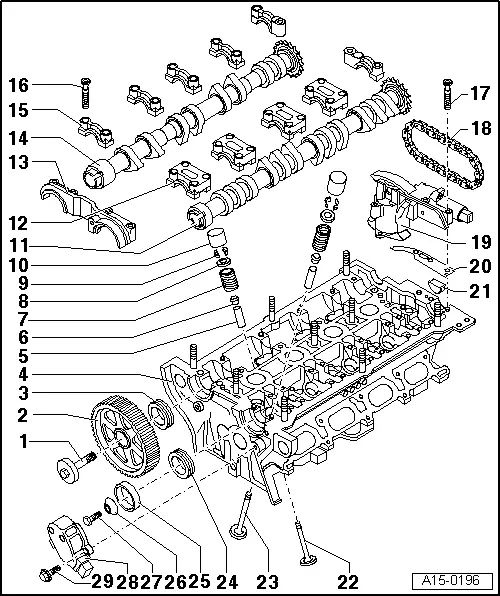

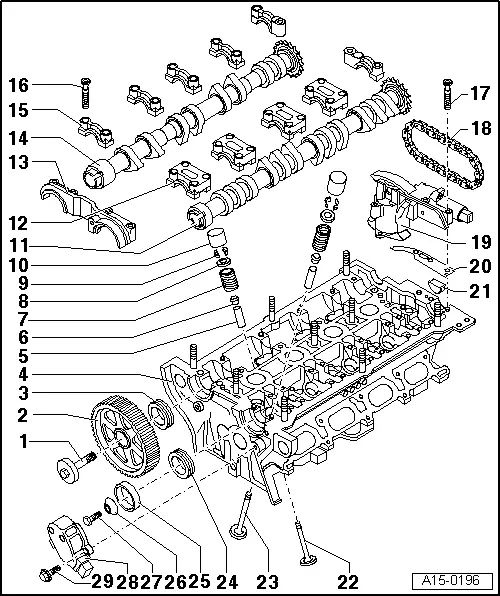

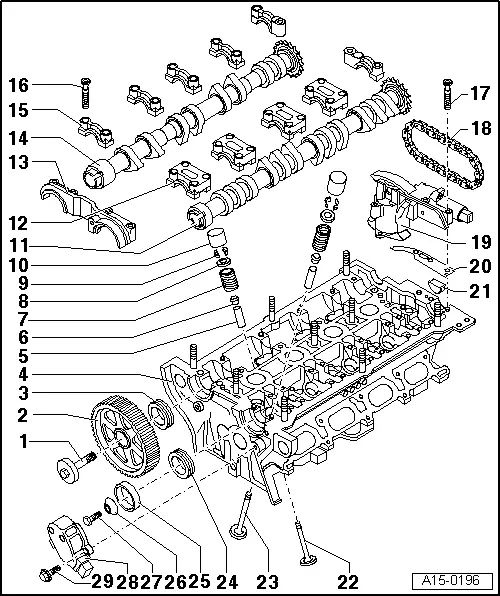

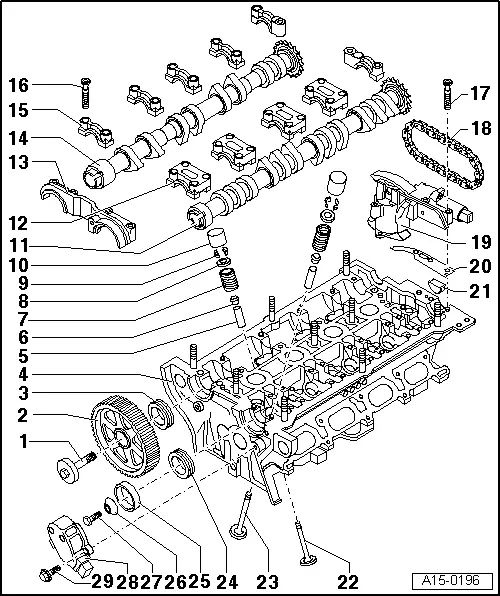

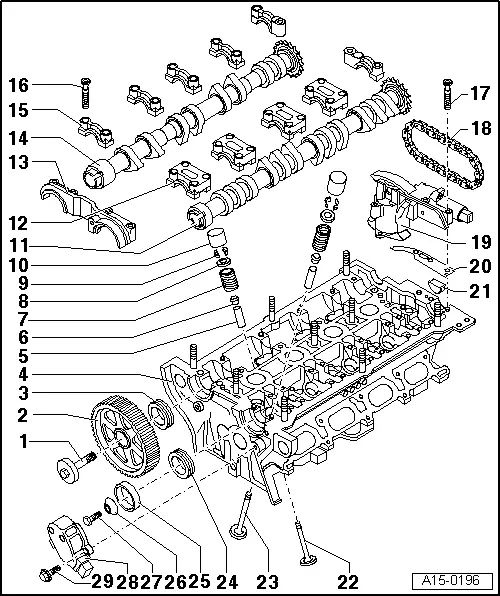

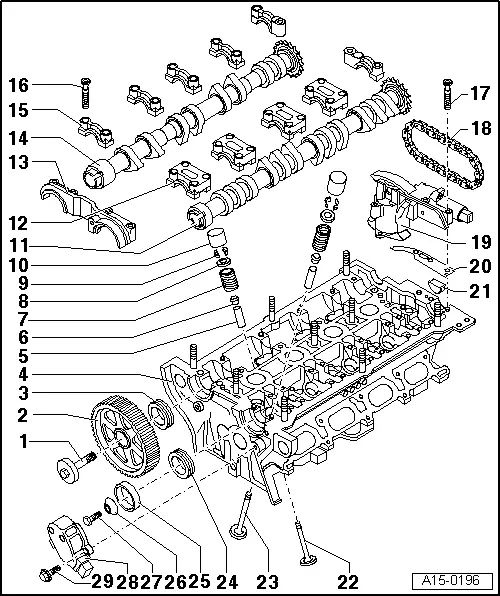

- Metal/rubber gasket

- Gasket

- Exhaust valve

-

◆ With sodium filling

-

◆ Note instructions on scrapping valves with a sodium filling => Page 15-43

-

◆ Do not rework, only grinding-in is permitted

-

◆ Valve dimensions => Fig. 1

-

◆ Checking valve guides, grinding in valve seats => Page 15-73

- Inlet valve

-

◆ Do not rework, only grinding-in is permitted

-

◆ Valve dimensions => Fig. 1

-

◆ Checking valve guides, grinding in valve seats => Page 15-73

|