A4 Mk1

| Removing engine |

| Special tools and workshop equipment required |

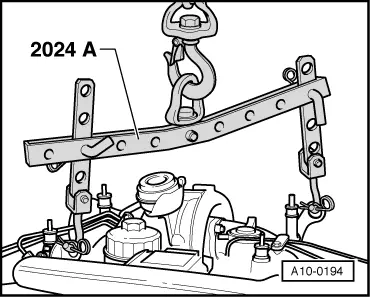

| t | Lifting tackle -2024 A- |

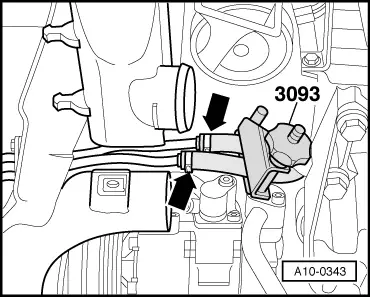

| t | Hose clamps for hoses up to 40 mm -3093- |

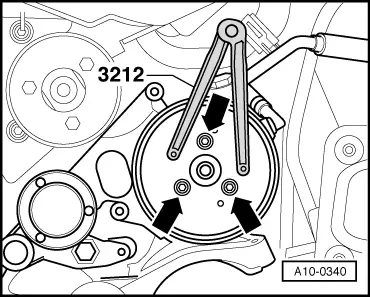

| t | Pin wrench -3212- |

| t | Open-end spanner -3312- |

| t | Hose clip pliers -V.A.G 1921- |

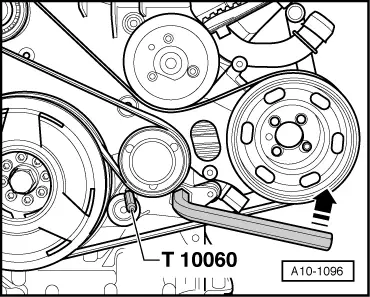

| t | Locking pin -T10060 A- |

| t | Used oil collection and extraction unit -V.A.G 1782- |

| t | Workshop hoist -VAS 6100- |

| t | Drip tray for workshop hoist -VAS 6208- |

| t | Special tool -V/175- for vehicles with automatic gearbox |

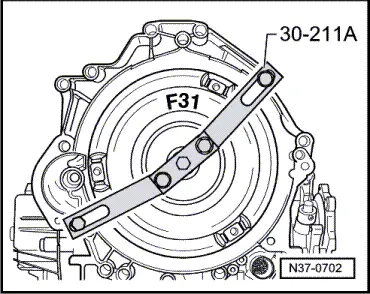

| t | Support bridge -30 - 211 A- for vehicles with automatic gearbox |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

Note

Note

Note

Note

|

|

|

|

|

|

Caution

Caution WARNING

WARNING