| Installation is carried out in the reverse order; note the following: |

Caution | Avoid damage to sealing surfaces. |

| t

| Carefully remove sealant residue from cylinder head and cylinder block. |

| t

| Ensure that no long scores or scratches are made on the surfaces. |

| Avoid damage to cylinder block. |

| No oil or coolant must be allowed to remain in the blind holes for the cylinder head bolts in the cylinder block. |

| Risk of leaks at cylinder head gasket. |

| t

| Carefully remove any sealant residue from the cylinder head and cylinder block. Ensure that no long scores or scratches are made on the surfaces. |

| t

| Carefully remove any remaining emery and abrasive material. |

| t

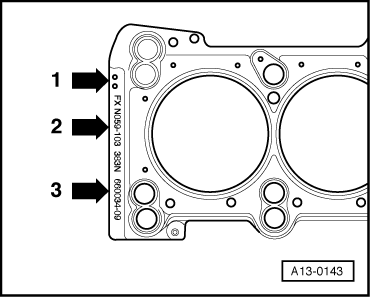

| Do not remove new cylinder head gasket from packaging until it is ready to be fitted. |

| t

| Handle the cylinder head gasket very carefully to prevent damage to the silicone coating or the indented area of the gasket. |

| Avoid damage to open valves. |

| When installing an exchange cylinder head, the plastic protectors fitted to protect the open valves should not be removed until the cylinder head is ready to be fitted. |

| Avoid damage to valves and piston crowns after working on valve gear. |

| Turn the engine carefully at least 2 rotations to ensure that none of the valves make contact when the starter is operated. |

|

Note | t

| Renew the bolts tightened with specified tightening angle. |

| t

| Renew self-locking nuts as well as seals, gaskets and O-rings. |

| t

| Cylinder heads must not be reworked on TDI engines. |

| t

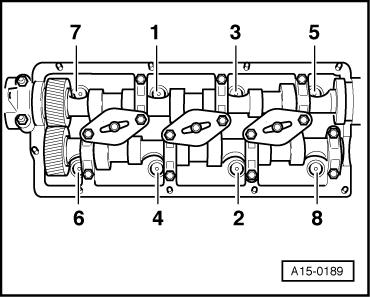

| When installing an exchange cylinder head with camshafts fitted, the contact surfaces between the hydraulic compensation elements, roller rocker fingers and cams must be oiled. |

| t

| Hose connections and air pipes and hoses must be free of oil and grease before assembly. |

| t

| After fitting a new cylinder head or cylinder head gasket, change the engine oil and coolant. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Caution

Caution