A4 Mk1

|

Servicing valve gear

Removing and installing camshafts and camshaft adjusters

Removing

|

|

|

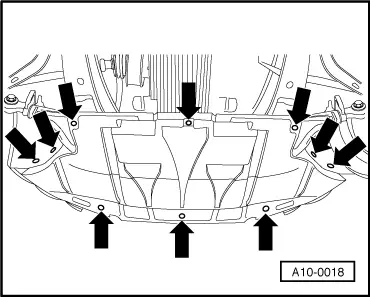

=> General body repairs; Repair group 63; Front bumper; Removing and installing front bumper

=> General body repairs; Repair Group 50; Removing and installing lock carrier; Service position of lock carrier

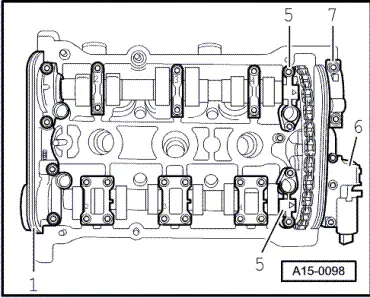

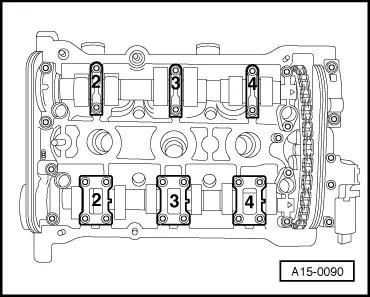

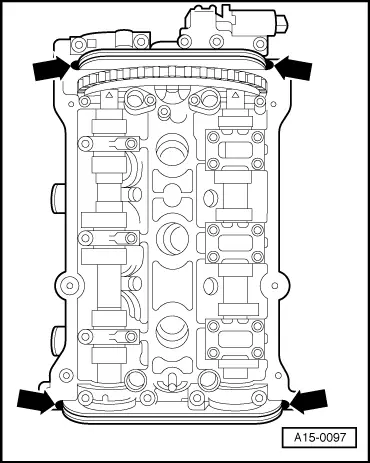

Left cylinder head:

Right cylinder head

All:

|

|

|

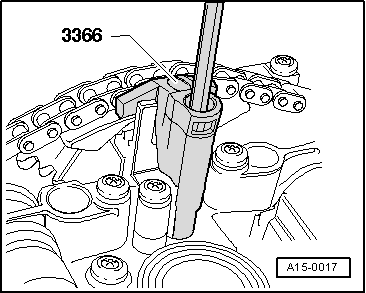

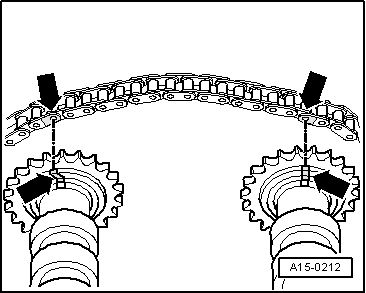

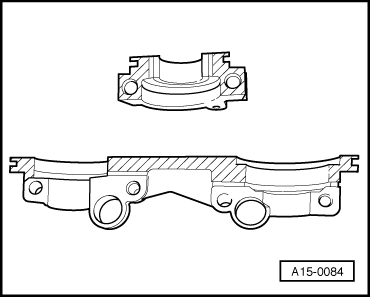

Make sure that the retaining catches do not break off when levering out the oil pipes. |

|

|

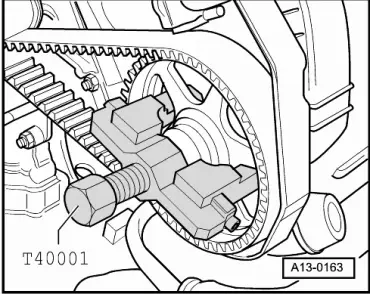

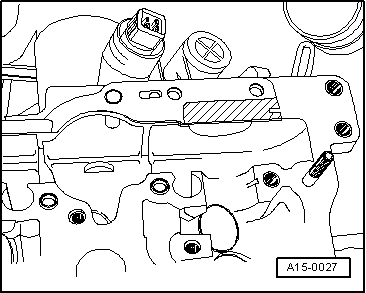

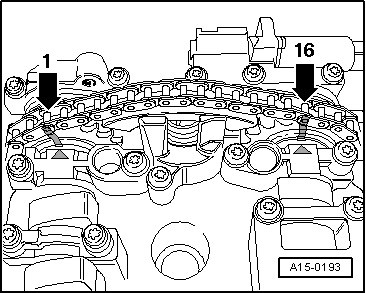

Note: Do not overtighten retainer for chain tensioner, otherwise camshaft adjuster can be damaged. |

|

|

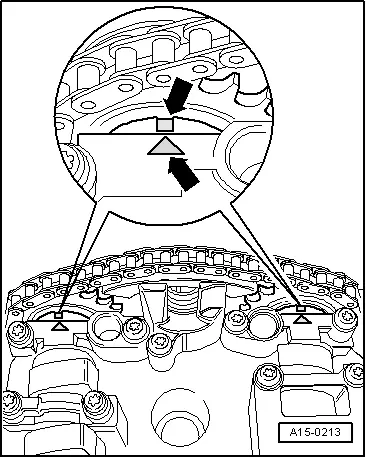

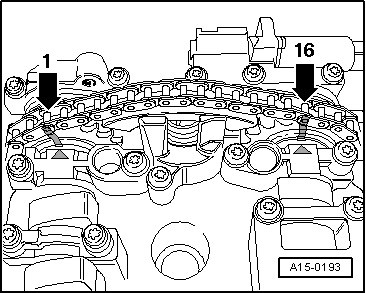

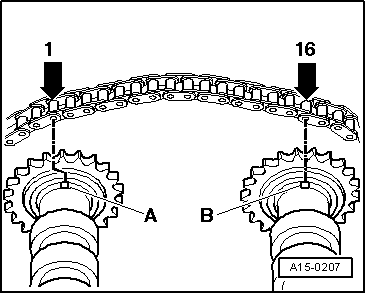

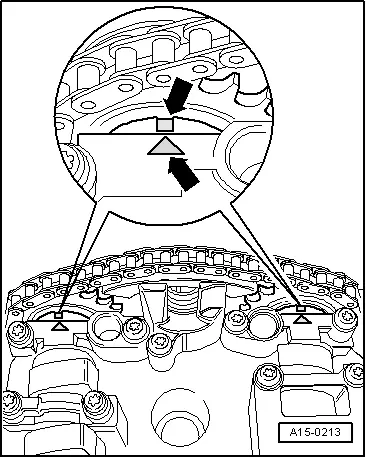

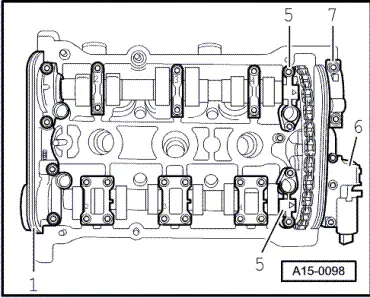

Note: The two markings on the camshafts must be in line with the two arrows on the bearing caps. |

|

|

|

Notes:

|

|

|

Installing |

|

|

|

|

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

=> Parts catalogue

Notes:

|

|

||||||||||||||||||||||||||||||

=> Parts Catalogue

Tightening torques

| ||||||||||||||||||||||||||||||